Hydrogen refueling stations are designed with multiple layers of safety to prevent leaks, fires, and explosions. Rigorous engineering standards, advanced detection systems, and extensive testing ensure they operate safely in public and private settings.

Key Takeaways

- Hydrogen is flammable but dissipates quickly: Unlike gasoline vapors, hydrogen rises and disperses rapidly in open air, reducing fire risk.

- Stations use multiple safety systems: Leak detectors, automatic shut-offs, ventilation, and fire suppression are standard.

- Strict international standards govern design: Codes like NFPA 2 and ISO 19887 ensure consistent safety across global stations.

- Real-world data shows low incident rates: Decades of operation in countries like Japan and Germany report minimal safety issues.

- Staff are trained for emergencies: Operators receive specialized training to handle leaks, spills, or equipment malfunctions.

- Hydrogen vehicles are built to protect fuel tanks: Composite tanks undergo extreme testing, including gunfire and crash simulations.

- Public perception lags behind reality: Misconceptions about hydrogen safety persist, but engineering and data prove its reliability.

Quick Answers to Common Questions

Are hydrogen refueling stations safe for the public?

Yes, hydrogen refueling stations are designed with public safety in mind. They use leak detectors, ventilation, and automatic shut-offs to prevent accidents. Thousands of stations operate safely worldwide.

Can a hydrogen station explode?

Explosions are extremely rare. Hydrogen disperses quickly, making large explosions unlikely. Most incidents involve small, short-lived fires that self-extinguish.

How do hydrogen stations compare to gas stations in safety?

Studies show hydrogen stations are no more dangerous than gas stations. Hydrogen’s rapid dispersion can actually make it safer in open areas.

What happens if there’s a hydrogen leak?

Sensors detect leaks immediately, triggering alarms and shutting off flow. Ventilation systems disperse the gas, and emergency protocols activate to protect people and equipment.

Are hydrogen fuel tanks safe in accidents?

Yes. Hydrogen tanks are tested to extreme conditions, including crashes, fires, and gunfire. They’re designed to prevent leaks or ruptures.

📑 Table of Contents

- Are Hydrogen Refueling Stations Safe? A Deep Dive into the Facts

- Understanding Hydrogen: The Fuel Behind the Future

- How Hydrogen Refueling Stations Work

- Safety Standards and Regulations

- Real-World Safety Performance

- Public Perception vs. Reality

- The Future of Hydrogen Safety

- Conclusion: Safety Through Design and Diligence

Are Hydrogen Refueling Stations Safe? A Deep Dive into the Facts

Imagine pulling up to a fueling station, but instead of gasoline or diesel, you’re filling your car with hydrogen gas. It sounds futuristic—maybe even a little intimidating. After all, hydrogen is the same element that powered the Hindenburg airship, which famously caught fire in 1937. That disaster left a lasting impression, and many people still associate hydrogen with danger. But today’s hydrogen refueling stations are nothing like the airships of the past. They’re built with cutting-edge technology, strict safety protocols, and decades of engineering refinement.

So, are hydrogen refueling stations safe? The short answer is yes—when designed, operated, and maintained correctly, they are among the safest alternative fueling options available. But let’s not just take that at face value. In this article, we’ll explore the science behind hydrogen, the engineering safeguards in place, real-world performance data, and how these stations compare to traditional fueling methods. Whether you’re a curious driver, a fleet manager, or just someone interested in clean energy, this guide will give you a clear, fact-based understanding of hydrogen safety.

Hydrogen is gaining momentum as a clean fuel alternative, especially for heavy-duty vehicles like buses, trucks, and forklifts. Countries like Japan, South Korea, Germany, and the United States are investing heavily in hydrogen infrastructure. California alone has over 50 hydrogen refueling stations, and more are planned. But with growth comes scrutiny—especially around safety. People want to know: Can I trust this technology? Will it explode? Is it safe to use near my home or workplace?

The good news is that hydrogen refueling stations are subject to rigorous safety standards and continuous monitoring. From the moment hydrogen is produced and transported to the point where it’s dispensed into a vehicle, every step is controlled and safeguarded. Let’s break down how these stations work and why they’re considered safe.

Understanding Hydrogen: The Fuel Behind the Future

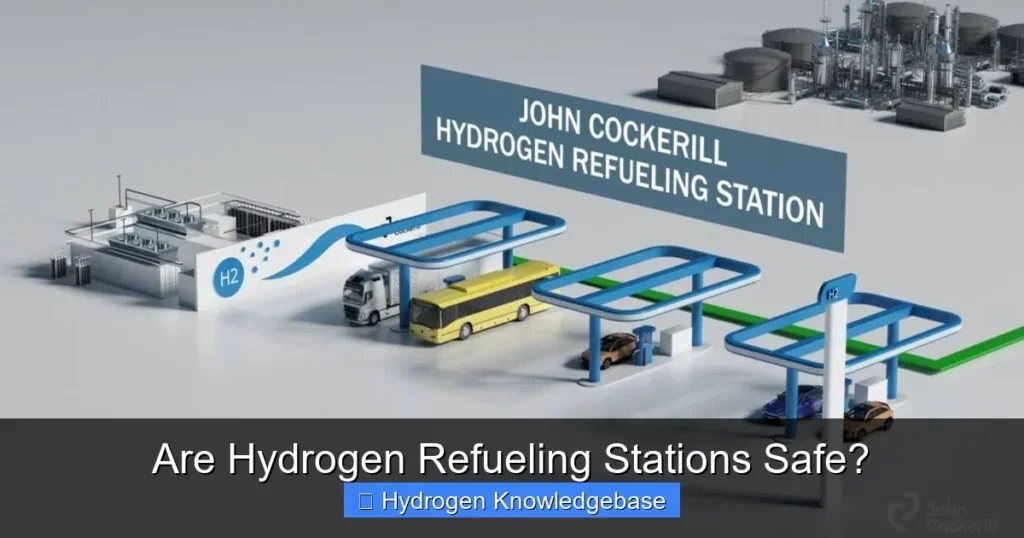

Visual guide about Are Hydrogen Refueling Stations Safe?

Image source: hydrogen.johncockerill.com

Before we dive into station safety, it’s important to understand what hydrogen is and how it behaves. Hydrogen (H₂) is the lightest and most abundant element in the universe. It’s colorless, odorless, and highly flammable—but that doesn’t automatically make it dangerous. In fact, many common substances we use daily, like gasoline and natural gas, are also flammable. The key is understanding how hydrogen compares to these fuels in terms of risk.

One of hydrogen’s most important safety advantages is its low density. Because it’s so light, it rises and disperses quickly when released into the air. Unlike gasoline vapors, which can pool near the ground and create explosive mixtures, hydrogen escapes upward, reducing the chance of ignition. This rapid dispersion is a major reason why hydrogen fires are often short-lived and localized.

Hydrogen vs. Gasoline: A Safety Comparison

Let’s compare hydrogen to gasoline, the fuel most people are familiar with. Gasoline is a liquid that evaporates into vapors, which are heavier than air and can accumulate in low-lying areas. A single spark can ignite these vapors, leading to large, sustained fires. In contrast, hydrogen gas is 14 times lighter than air. If a leak occurs, it shoots upward and dissipates within seconds—especially in open or well-ventilated areas.

Another key difference is ignition energy. Hydrogen requires less energy to ignite than gasoline—about 10 times less. But this doesn’t mean it’s more dangerous. In fact, the low ignition energy means hydrogen can ignite more easily in controlled environments, which is useful for fuel cells. But in an accidental release, the quick dispersion often prevents sustained combustion.

Hydrogen in Fuel Cells: Clean Energy, Minimal Emissions

Most hydrogen-powered vehicles use fuel cells, not internal combustion engines. In a fuel cell, hydrogen reacts with oxygen to produce electricity, with water vapor as the only emission. This process is quiet, efficient, and produces zero greenhouse gases during operation. The hydrogen is stored in high-strength composite tanks on the vehicle, designed to withstand extreme conditions.

These tanks are tested to rigorous standards. They’re shot with bullets, crushed, exposed to fire, and subjected to pressure far beyond normal operating levels. The goal is to ensure they won’t rupture or leak, even in a severe accident. This level of testing gives engineers and regulators confidence in the safety of hydrogen storage.

How Hydrogen Refueling Stations Work

Now that we understand hydrogen’s properties, let’s look at how refueling stations operate. A typical hydrogen station has several key components: a hydrogen source (on-site production or delivery), compression and storage systems, dispensers, and safety controls.

Hydrogen Production and Delivery

Hydrogen can be produced in several ways. The most common method today is steam methane reforming, which uses natural gas. While this process isn’t completely carbon-free, it’s still cleaner than gasoline. The future goal is green hydrogen, produced using renewable energy to split water into hydrogen and oxygen via electrolysis.

Hydrogen is delivered to stations either by tube trailers (high-pressure gas) or liquid tankers (cryogenic liquid). Both methods are well-established and regulated. Tube trailers are like long cylinders on a truck, carrying compressed hydrogen at up to 700 bar (10,000 psi). Liquid hydrogen is cooled to -253°C (-423°F) and stored in insulated tanks.

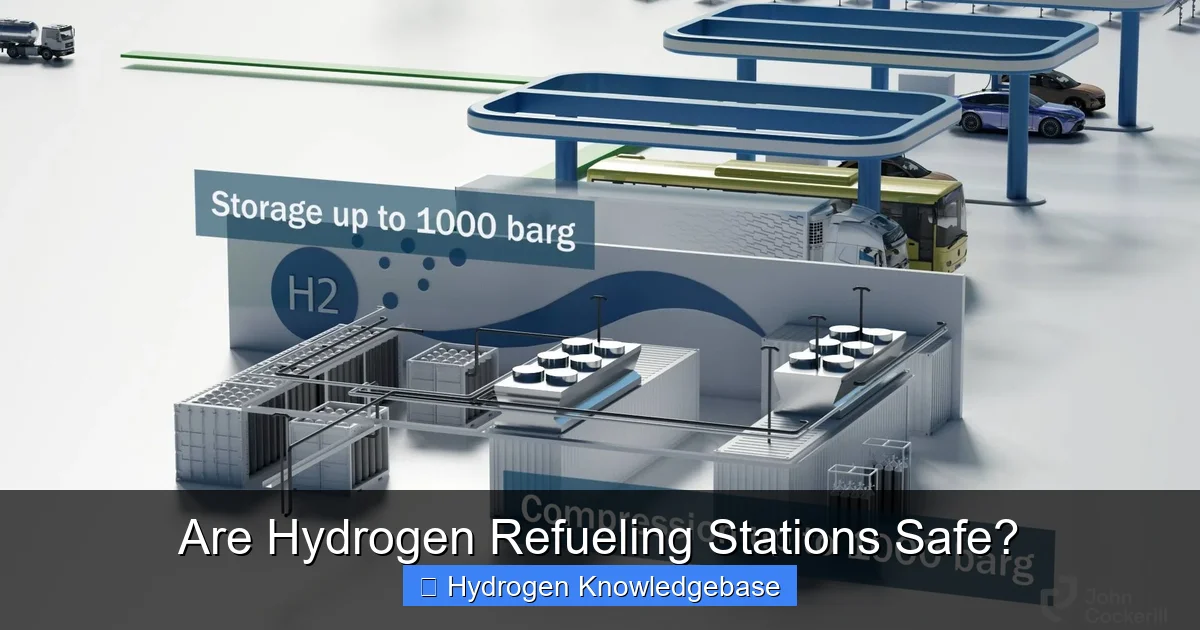

Compression, Storage, and Dispensing

At the station, hydrogen is compressed further and stored in high-pressure tanks. These tanks are made of advanced composites and steel, designed to handle extreme pressures. They’re also equipped with pressure relief devices (PRDs) that release gas safely if pressure gets too high.

When a vehicle arrives, the driver connects a dispenser nozzle to the car’s fuel port. The system checks for leaks and ensures a secure connection before fueling begins. The hydrogen flows into the vehicle’s tank under controlled pressure. The entire process takes about 3 to 5 minutes—similar to gasoline refueling.

Safety Systems in Action

Every hydrogen station is equipped with multiple safety systems. These include:

– **Leak detectors:** Sensors monitor for hydrogen leaks in real time. If a leak is detected, the system can shut off flow and alert operators.

– **Ventilation:** Stations are designed with open layouts and forced ventilation to prevent gas buildup.

– **Fire suppression:** Some stations have water deluge systems or inert gas suppression to control fires.

– **Emergency shutdowns:** Manual and automatic shut-off valves stop hydrogen flow in case of fire, earthquake, or other emergencies.

– **Barriers and signage:** Physical barriers protect equipment, and clear signage warns of hazards.

These systems work together to minimize risk and respond quickly to any incident.

Safety Standards and Regulations

Hydrogen refueling stations don’t operate in a regulatory vacuum. They must comply with strict international codes and standards. These rules cover everything from design and construction to operation and maintenance.

Key Safety Standards

One of the most important standards is **NFPA 2: Hydrogen Technologies Code**, developed by the National Fire Protection Association. This code sets requirements for hydrogen production, storage, handling, and dispensing. It’s used in the U.S. and referenced globally.

Another key standard is **ISO 19887**, which focuses on hydrogen fueling stations for vehicles. It covers safety distances, ventilation, and equipment specifications. The European Union also has its own regulations under the Alternative Fuels Infrastructure Directive.

These standards are updated regularly based on new research and real-world experience. For example, after early hydrogen stations showed minor leaks, standards were revised to require more frequent inspections and better sealing materials.

Certification and Inspections

Before a hydrogen station can open, it must be certified by local authorities and third-party inspectors. This process includes design review, equipment testing, and safety drills. Stations are also subject to regular inspections—often annually or biannually—to ensure compliance.

In California, the state’s Air Resources Board (CARB) oversees hydrogen station safety. They require detailed risk assessments and emergency response plans. Operators must also report any incidents, no matter how minor.

Real-World Safety Performance

Theory and standards are important, but what about real-world performance? How have hydrogen stations actually performed over time?

Global Experience

Countries with the most hydrogen infrastructure—Japan, South Korea, Germany, and the U.S.—have operated stations for over a decade with very few safety incidents. Japan, for example, has more than 160 hydrogen stations and has reported no major accidents. Germany’s H2 Mobility network has over 100 stations and a strong safety record.

In the U.S., the Department of Energy tracks hydrogen safety data through its Hydrogen Incident Reporting Database. Since 2005, there have been fewer than 50 reported incidents at hydrogen stations—most involving minor leaks or equipment malfunctions. None have resulted in serious injury or fatalities.

Case Study: California’s Hydrogen Network

California is a leader in hydrogen infrastructure. The state’s first public hydrogen station opened in 2012. Since then, over 50 stations have been built, serving thousands of fuel cell vehicles. According to the California Fuel Cell Partnership, there have been no major safety incidents.

One station in San Ramon experienced a small leak in 2019 due to a faulty seal. The leak was detected immediately, the system shut down automatically, and no one was injured. The issue was repaired within hours. This incident highlights how safety systems work in practice—detecting problems early and preventing escalation.

Lessons from Incidents

While incidents are rare, they provide valuable lessons. Most issues stem from human error, equipment wear, or improper maintenance—not fundamental flaws in hydrogen technology. For example, a 2019 incident in Norway involved a hydrogen explosion at a filling station. Investigation revealed that a faulty valve allowed hydrogen to mix with air in a compressor, creating an explosive mixture. The station was not following proper maintenance procedures.

This incident led to stricter maintenance requirements and better training for technicians. It also reinforced the importance of following safety protocols—even for experienced operators.

Public Perception vs. Reality

Despite strong safety records, public perception of hydrogen remains mixed. Many people still associate hydrogen with the Hindenburg disaster or nuclear explosions. These fears are understandable but outdated.

Addressing Common Misconceptions

Let’s tackle a few myths:

– **Myth: Hydrogen stations can explode like bombs.**

Reality: Hydrogen disperses too quickly to create large explosions. Most incidents involve small, localized fires that self-extinguish.

– **Myth: Hydrogen is more dangerous than gasoline.**

Reality: Studies show hydrogen is no more dangerous than gasoline when proper safety measures are in place. In some ways, it’s safer due to rapid dispersion.

– **Myth: Hydrogen leaks are hard to detect.**

Reality: Modern sensors can detect hydrogen at concentrations as low as 1%—well below the flammability limit (4%). Many stations also use odorants or visual indicators.

Building Public Trust

To build trust, station operators and governments are increasing transparency. Many stations offer public tours, safety demonstrations, and educational materials. In Japan, hydrogen stations are often located in urban areas, showing that they can coexist safely with homes and businesses.

Social media and news coverage also play a role. When incidents occur, timely and accurate reporting helps prevent panic and misinformation.

The Future of Hydrogen Safety

As hydrogen technology evolves, so do safety practices. Researchers are developing even better materials, sensors, and automation to reduce risk.

Advancements in Technology

New composite tanks are lighter and stronger, reducing the chance of failure. Smart sensors can predict equipment wear before it becomes a problem. Some stations now use AI to monitor operations and detect anomalies in real time.

Green hydrogen production is also improving. As renewable energy becomes cheaper, more stations will use on-site solar or wind power to produce hydrogen, reducing transportation risks.

Expanding Infrastructure

The global hydrogen market is expected to grow rapidly. By 2030, countries like Germany and Japan aim to have hundreds of stations. The U.S. has announced plans to build a national hydrogen network, with funding from the Infrastructure Investment and Jobs Act.

With more stations comes more data, better standards, and improved safety. Each new station benefits from lessons learned at previous ones.

Conclusion: Safety Through Design and Diligence

So, are hydrogen refueling stations safe? The evidence says yes. They are built with multiple layers of protection, governed by strict standards, and operated by trained professionals. Real-world experience shows that incidents are rare and typically minor.

Hydrogen is not without risks—no fuel is. But with proper engineering, maintenance, and oversight, those risks are managed effectively. As the world shifts toward cleaner energy, hydrogen stations will play a key role in reducing emissions and improving air quality.

The next time you see a hydrogen station, don’t think of the Hindenburg. Think of advanced technology, rigorous safety, and a cleaner future. Hydrogen isn’t just safe—it’s a smart choice for the planet.

Frequently Asked Questions

What safety features do hydrogen refueling stations have?

Hydrogen stations include leak detectors, automatic shut-off valves, ventilation systems, fire suppression, and emergency controls. These features work together to prevent and respond to incidents.

How often are hydrogen stations inspected?

Most stations are inspected annually or biannually by certified inspectors. Some jurisdictions require more frequent checks, especially after incidents or equipment changes.

Can hydrogen stations be located near homes or schools?

Yes, many hydrogen stations are safely located in urban and suburban areas. Safety standards require proper setbacks, ventilation, and emergency planning to protect nearby communities.

What training do hydrogen station operators receive?

Operators undergo specialized training in hydrogen safety, emergency response, and equipment maintenance. Training covers leak detection, fire response, and communication protocols.

Is hydrogen more dangerous than natural gas?

Hydrogen and natural gas have similar flammability, but hydrogen disperses faster. Both require careful handling, but hydrogen’s quick rise reduces the risk of accumulation.

What should I do if I smell hydrogen near a station?

Hydrogen is odorless, but some systems add odorants for detection. If you suspect a leak, leave the area immediately and call emergency services. Do not use electronic devices or create sparks.