Fuel cell technology is rapidly advancing, making hydrogen-powered vehicles more efficient, affordable, and practical. With innovations in materials, infrastructure, and manufacturing, these clean-energy cars are becoming a viable alternative to traditional engines.

Key Takeaways

- Increased Efficiency: Modern fuel cells convert hydrogen to electricity with over 60% efficiency, far surpassing internal combustion engines.

- Longer Driving Range: Newer hydrogen vehicles can travel 300–400 miles on a single tank, rivaling gasoline-powered cars.

- Faster Refueling: Refilling a hydrogen tank takes just 3–5 minutes, much quicker than charging an EV.

- Improved Durability: Advances in membrane and catalyst materials extend fuel cell lifespan to over 200,000 miles.

- Growing Infrastructure: More hydrogen refueling stations are being built, especially in California, Japan, and Europe.

- Cost Reduction: Mass production and innovation are lowering the cost of fuel cells and hydrogen storage systems.

- Zero Emissions: Fuel cell vehicles emit only water vapor, making them a key player in the clean transportation future.

[FEATURED_IMAGE_PLACEHOLDER]

How Fuel Cell Technology Is Improving in Vehicles

Imagine driving a car that runs on hydrogen, refuels in minutes, and leaves behind nothing but water vapor. Sounds like science fiction? It’s not. Fuel cell technology is making this vision a reality—and it’s improving faster than ever. While electric vehicles (EVs) have dominated the clean transportation conversation, hydrogen fuel cell vehicles (FCVs) are quietly gaining momentum as a powerful alternative.

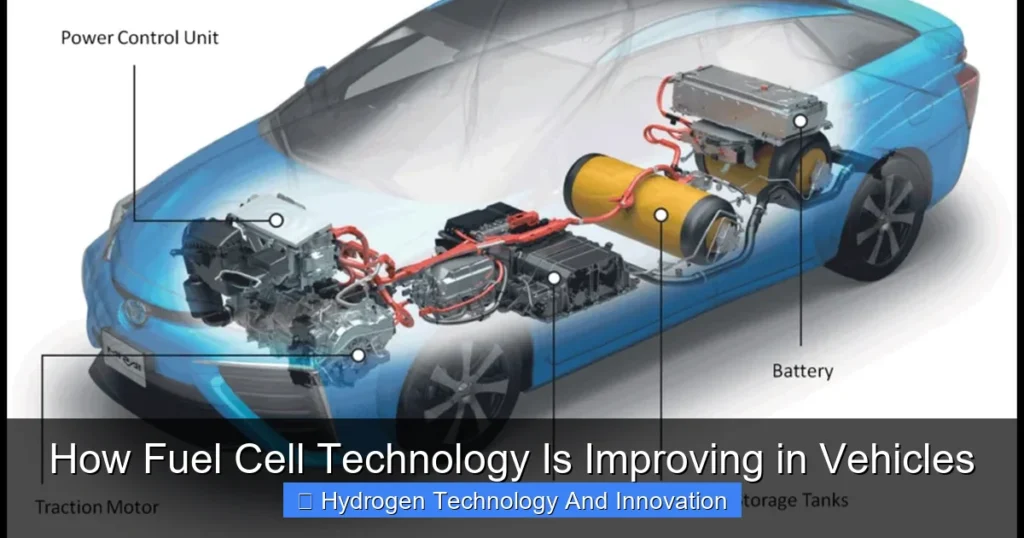

Fuel cell technology uses hydrogen gas to generate electricity through a chemical reaction, powering an electric motor. Unlike battery-powered EVs that rely on large, heavy batteries, FCVs produce their own electricity on board. This means they can offer long range and quick refueling—two major advantages over current EVs. And as technology advances, these benefits are becoming even more pronounced.

The journey of fuel cell vehicles hasn’t been without challenges. High costs, limited infrastructure, and questions about hydrogen production have slowed adoption. But recent breakthroughs in materials science, manufacturing, and energy systems are changing the game. From more durable membranes to smarter thermal management, engineers are solving old problems and unlocking new potential. As a result, fuel cell vehicles are becoming more efficient, reliable, and accessible.

What Is Fuel Cell Technology and How Does It Work?

At its core, a fuel cell is an electrochemical device that converts hydrogen and oxygen into electricity, water, and heat. It works much like a battery, but instead of storing energy, it generates it continuously as long as fuel is supplied. This makes fuel cells ideal for vehicles that need long range and fast refueling.

The heart of a fuel cell is the proton exchange membrane (PEM), a thin, polymer-based material that allows protons to pass through while blocking electrons. When hydrogen gas is fed into the anode side of the fuel cell, a catalyst—usually platinum—splits the hydrogen atoms into protons and electrons. The protons move through the membrane to the cathode, while the electrons are forced to travel through an external circuit, creating an electric current. At the cathode, oxygen from the air combines with the protons and electrons to form water.

This process is clean, quiet, and highly efficient. Unlike internal combustion engines, which waste a lot of energy as heat, fuel cells convert chemical energy directly into electricity with minimal loss. Modern PEM fuel cells can achieve efficiencies of 60% or higher, compared to about 20–30% for gasoline engines.

Types of Fuel Cells Used in Vehicles

Not all fuel cells are the same. While PEM fuel cells dominate the automotive industry, other types are being explored for specific applications.

PEM Fuel Cells are the most common in vehicles due to their quick start-up time, high power density, and ability to operate at relatively low temperatures (around 80°C). They’re ideal for cars, buses, and trucks.

Solid Oxide Fuel Cells (SOFCs) operate at much higher temperatures (700–1,000°C) and are more efficient, but they’re slower to start and better suited for stationary power or heavy-duty applications like ships and trains.

Alkaline Fuel Cells (AFCs) were used in early space missions but are less common today due to sensitivity to carbon dioxide.

For now, PEM remains the gold standard for road vehicles, but research into alternative materials and designs could expand options in the future.

The Role of Hydrogen in Fuel Cell Vehicles

Hydrogen is the fuel that powers fuel cell vehicles. It’s the most abundant element in the universe and can be produced from a variety of sources, including natural gas, water electrolysis, and even biomass.

When hydrogen is produced using renewable energy—like solar or wind power—through a process called electrolysis, the entire lifecycle of the fuel becomes nearly emission-free. This is known as “green hydrogen” and is a key goal for sustainable transportation.

However, most hydrogen today is still made from natural gas in a process called steam methane reforming, which does produce carbon emissions. This is why the environmental benefits of fuel cell vehicles depend heavily on how the hydrogen is made.

Still, even with current production methods, FCVs often have a lower carbon footprint than gasoline cars, especially when considering the full lifecycle. As green hydrogen production scales up, the environmental case for fuel cells will only get stronger.

Recent Advances in Fuel Cell Efficiency and Performance

One of the biggest challenges for early fuel cell vehicles was efficiency. While the theoretical efficiency of fuel cells is high, real-world performance was often limited by heat loss, material degradation, and energy used to run auxiliary systems like air compressors and humidifiers.

Today, engineers are overcoming these hurdles with smarter designs and better materials.

Higher Power Density and Compact Designs

Modern fuel cells are smaller, lighter, and more powerful than ever. Thanks to advances in membrane technology and catalyst design, manufacturers can pack more power into less space. For example, Toyota’s latest Mirai fuel cell stack is 20% smaller and 15% lighter than its predecessor, yet delivers more power.

This means automakers can design sleeker, more aerodynamic vehicles without sacrificing performance. It also opens the door for fuel cells in smaller cars, not just SUVs and sedans.

Improved Catalyst Materials

Platinum has long been the catalyst of choice in PEM fuel cells because it efficiently splits hydrogen atoms. But platinum is rare and expensive, driving up costs.

Researchers are now developing platinum-free or low-platinum catalysts using materials like iron, nitrogen, and carbon. These alternatives can match or even exceed the performance of traditional catalysts while reducing costs by up to 50%.

For instance, a team at the University of California, Los Angeles (UCLA) created a catalyst using cobalt and nitrogen that performs nearly as well as platinum. If commercialized, such innovations could make fuel cells far more affordable.

Better Thermal and Water Management

Fuel cells need to stay within a narrow temperature and humidity range to work efficiently. Too dry, and the membrane cracks. Too wet, and the electrodes flood.

New systems use advanced sensors and software to monitor and adjust conditions in real time. Some designs even recycle water produced during the reaction to keep the membrane hydrated.

These improvements not only boost efficiency but also extend the life of the fuel cell. Where early stacks might last 5,000 hours, today’s models can exceed 20,000 hours—enough for over 200,000 miles of driving.

Hybrid Systems for Enhanced Performance

Some manufacturers are combining fuel cells with small batteries or supercapacitors to create hybrid systems. These setups allow the fuel cell to operate at a steady, efficient load while the battery handles peak power demands, like acceleration.

For example, the Hyundai NEXO uses a hybrid approach to deliver instant torque and smooth power delivery. This not only improves driving dynamics but also reduces wear on the fuel cell, increasing its lifespan.

Durability and Lifespan Improvements

One of the biggest concerns with early fuel cell vehicles was how long the fuel cells would last. Exposure to extreme temperatures, frequent start-stop cycles, and impurities in the hydrogen could degrade components over time.

But thanks to better materials and smarter operating strategies, modern fuel cells are far more durable.

Longer-Lasting Membranes

The proton exchange membrane is critical to fuel cell performance, but it’s also vulnerable to damage. Over time, the membrane can thin, crack, or lose its ability to conduct protons.

Newer membranes are made from reinforced polymers that resist chemical and mechanical stress. Some even incorporate self-healing properties that repair minor damage automatically.

For example, Chemours, a leading materials company, has developed a membrane that maintains performance even after thousands of humidity cycles. This kind of resilience is key to long-term reliability.

Reduced Degradation from Start-Stop Cycles

Frequent starting and stopping can cause voltage spikes that degrade fuel cell components. To combat this, engineers have developed voltage control systems that smooth out power delivery and reduce stress on the stack.

Some vehicles also use a “keep-warm” mode that maintains a low power output when parked, preventing the fuel cell from cooling completely. This reduces the strain of cold starts and extends component life.

Real-World Testing and Validation

Automakers are putting fuel cells through rigorous testing to ensure they can handle real-world conditions. Toyota, for instance, has driven its Mirai over 1 million miles in extreme climates—from the deserts of Arizona to the snowy roads of Canada.

These tests have helped identify weak points and refine designs. As a result, manufacturers now offer warranties of up to 10 years or 150,000 miles on fuel cell systems, giving consumers confidence in their longevity.

Cost Reduction Through Innovation and Scale

One of the biggest barriers to widespread adoption of fuel cell vehicles has been cost. Fuel cells were expensive to produce, and hydrogen storage systems added even more to the price tag.

But that’s changing fast.

Economies of Scale in Manufacturing

As production volumes increase, costs naturally fall. Toyota, Hyundai, and Honda have all ramped up production of their fuel cell models, allowing them to spread development costs over more units.

For example, Toyota has reduced the cost of its fuel cell stack by over 80% since the first Mirai launched in 2014. Much of this comes from standardized parts, automated assembly, and supplier partnerships.

Cheaper Hydrogen Storage Solutions

Storing hydrogen safely and efficiently has always been a challenge. High-pressure tanks are heavy and expensive, but new materials are making them lighter and stronger.

Type IV carbon fiber tanks, which use a plastic liner wrapped in carbon fiber, are now standard in most FCVs. These tanks can withstand pressures of 700 bar (over 10,000 psi) while being significantly lighter than older steel tanks.

Companies like Hexagon Purus and ILJIN Composite are pushing the envelope with even lighter, more durable designs. Some are exploring liquid organic hydrogen carriers (LOHCs) or metal hydrides that store hydrogen at lower pressures.

Government Incentives and Investment

Governments around the world are investing in hydrogen infrastructure and offering incentives to make FCVs more affordable. In the U.S., the Inflation Reduction Act includes tax credits for hydrogen production and fuel cell vehicles.

California offers rebates of up to $5,000 for FCV purchases and has invested over $200 million in hydrogen refueling stations. Similar programs exist in Japan, South Korea, and the European Union.

These incentives help bridge the gap between FCVs and conventional vehicles, making them more accessible to everyday drivers.

Expanding Hydrogen Infrastructure

No matter how good the technology, fuel cell vehicles can’t succeed without a reliable way to refuel. That’s why building a hydrogen refueling network is critical.

Growth in Refueling Stations

The number of hydrogen stations is growing, especially in regions with strong government support. As of 2024, California has over 60 public hydrogen stations, with plans to reach 200 by 2030. Japan has more than 160 stations, and Germany is rapidly expanding its network.

These stations use high-pressure dispensers that can refill a tank in 3–5 minutes—about the same time as a gasoline fill-up. That’s a huge advantage over EVs, which can take 30 minutes to several hours to recharge.

Mobile and On-Site Refueling

For fleet operators and remote areas, mobile refueling units are becoming more common. These truck-mounted systems can deliver hydrogen directly to vehicles, reducing the need for fixed infrastructure.

Some companies are also exploring on-site hydrogen production using electrolyzers powered by solar or wind. This could allow businesses, truck stops, or even homes to generate their own hydrogen.

Challenges in Distribution and Safety

Hydrogen is a small, light molecule that can leak easily and is highly flammable. That means storage and transport require strict safety protocols.

But modern systems are designed with multiple layers of protection, including leak detectors, pressure relief valves, and flame arrestors. Training and regulations ensure that station operators handle hydrogen safely.

As the technology matures, public confidence in hydrogen safety is growing. In fact, hydrogen has a strong safety record in industrial applications, and FCVs undergo rigorous crash and fire testing.

Environmental Impact and Sustainability

One of the biggest selling points of fuel cell vehicles is their environmental benefit. But how green are they really?

Zero Tailpipe Emissions

The most obvious advantage is that FCVs emit only water vapor from the tailpipe. No carbon dioxide, no nitrogen oxides, no particulate matter. This makes them ideal for reducing urban air pollution.

In cities like Los Angeles or Tokyo, where smog and respiratory issues are a concern, FCVs can make a real difference.

Lifecycle Emissions Depend on Hydrogen Source

While the vehicle itself is clean, the environmental impact depends on how the hydrogen is made.

Green hydrogen, produced from renewable energy, has a near-zero carbon footprint. Blue hydrogen, made from natural gas with carbon capture, is cleaner than gray hydrogen but still emits some CO₂.

Currently, about 95% of hydrogen is “gray”—produced from fossil fuels without carbon capture. But the shift to green hydrogen is accelerating.

Countries like Australia, Saudi Arabia, and Canada are investing billions in renewable hydrogen projects. The European Union aims to produce 10 million tons of green hydrogen annually by 2030.

Recycling and End-of-Life Management

Like all vehicles, FCVs need to be recycled responsibly. Fuel cells contain precious metals like platinum, which can be recovered and reused.

Automakers are designing FCVs with disassembly in mind, making it easier to recover valuable materials. Some companies are also exploring closed-loop recycling systems where old fuel cells are refurbished or remanufactured.

Real-World Applications and Success Stories

Fuel cell technology isn’t just for passenger cars. It’s being used in a wide range of vehicles and applications.

Passenger Vehicles

Toyota’s Mirai, Hyundai’s NEXO, and Honda’s Clarity Fuel Cell are leading the way in the consumer market. These vehicles offer luxury features, long range, and fast refueling.

The Mirai, for example, has a range of over 400 miles and can refuel in under 5 minutes. It’s popular in California, where drivers value its zero-emission performance and convenience.

Commercial and Heavy-Duty Vehicles

Fuel cells are especially well-suited for trucks, buses, and delivery vans that need long range and quick refueling.

Companies like Nikola, Hyzon, and Toyota are developing hydrogen-powered semi-trucks. The Toyota Kenworth T680 FCEV can travel up to 300 miles and is being tested in California’s ports.

In transit, cities like Aberdeen, Scotland, and Cologne, Germany, operate hydrogen buses that reduce emissions and noise pollution.

Specialty and Emerging Uses

Fuel cells are also being used in forklifts, airport ground support equipment, and even ships. The Port of Los Angeles is testing hydrogen-powered cargo handlers, and the world’s first hydrogen ferry is operating in Norway.

These niche applications help build demand, drive innovation, and create a market for hydrogen infrastructure.

The Future of Fuel Cell Technology in Vehicles

The future looks bright for fuel cell technology. As costs fall, efficiency rises, and infrastructure expands, FCVs are poised to play a major role in the clean transportation revolution.

Integration with Renewable Energy

One exciting possibility is using excess renewable energy to produce hydrogen during off-peak hours. This “power-to-gas” approach could help balance the grid and store energy for later use.

Imagine solar farms generating hydrogen at noon, which is then used to power vehicles at night. It’s a sustainable cycle that maximizes clean energy.

Autonomous and Connected FCVs

As self-driving technology advances, fuel cell vehicles are a natural fit. Their long range and fast refueling make them ideal for autonomous taxis and delivery fleets.

Companies like Waymo and Cruise are exploring hydrogen options for their robotaxi services, especially in regions with hydrogen infrastructure.

Global Expansion

While FCVs are currently concentrated in a few countries, global adoption is growing. China is investing heavily in hydrogen, with plans for over 1,000 refueling stations by 2030. India and Brazil are also exploring fuel cell buses and trucks.

With international cooperation and shared standards, hydrogen could become a global fuel for clean transportation.

Conclusion

Fuel cell technology is no longer a futuristic dream—it’s a real, improving, and increasingly practical solution for clean transportation. From higher efficiency and longer lifespan to faster refueling and lower costs, the advancements are impressive.

While challenges remain—especially in hydrogen production and infrastructure—the progress is undeniable. With continued innovation, investment, and policy support, fuel cell vehicles could become a mainstream choice for drivers who want zero emissions without sacrificing range or convenience.

The road ahead is hydrogen-powered, and it’s looking clearer every day.

FAQs

How does a fuel cell vehicle compare to an electric vehicle?

Fuel cell vehicles (FCVs) use hydrogen to generate electricity on board, offering long range and fast refueling. EVs rely on large batteries that take longer to charge. FCVs are better for long trips and heavy-duty use, while EVs excel in city driving and home charging.

Is hydrogen safe to use in vehicles?

Yes, hydrogen is safe when handled properly. Modern FCVs have multiple safety systems, including leak detectors and pressure relief valves. Hydrogen disperses quickly in air, reducing fire risk compared to gasoline.

How long does it take to refuel a hydrogen vehicle?

Refueling a hydrogen vehicle takes just 3–5 minutes, similar to filling a gas tank. This is much faster than charging most electric vehicles.

Where can I refuel a hydrogen car?

Hydrogen stations are available in select regions, especially California, Japan, South Korea, and parts of Europe. The network is growing, with plans to expand significantly in the coming years.

Are fuel cell vehicles really zero emission?

FCVs emit only water vapor from the tailpipe. However, the overall environmental impact depends on how the hydrogen is produced. Green hydrogen, made from renewables, offers near-zero lifecycle emissions.

What is the range of a typical fuel cell vehicle?

Most modern FCVs have a range of 300–400 miles on a full tank, comparable to gasoline vehicles and longer than many EVs.

This is a comprehensive guide about How fuel cell technology is improving in vehicles.

Key Takeaways

- Understanding How fuel cell technology is improving in vehicles: Provides essential knowledge

Frequently Asked Questions

What is How fuel cell technology is improving in vehicles?

How fuel cell technology is improving in vehicles is an important topic with many practical applications.