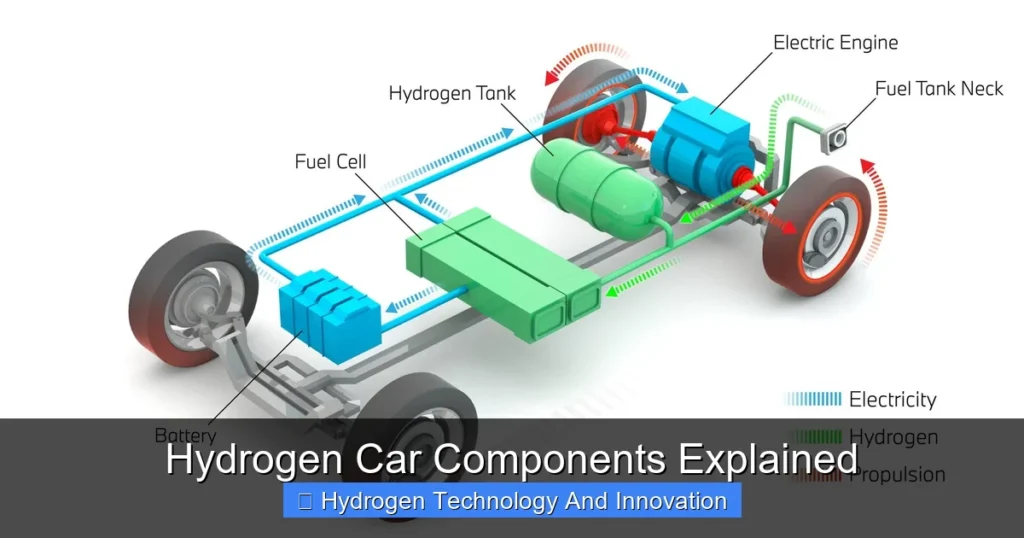

Hydrogen cars are powered by advanced components that convert hydrogen gas into clean electricity. From fuel cells to storage tanks, each part plays a vital role in delivering zero-emission driving with quick refueling and long range.

Key Takeaways

- Fuel cell stacks are the heart of hydrogen cars: They convert hydrogen and oxygen into electricity, powering the motor with only water as a byproduct.

- High-pressure hydrogen tanks store fuel safely: Made from carbon fiber, these tanks hold compressed hydrogen at up to 700 bar for long driving ranges.

- Electric motors drive the wheels efficiently: Hydrogen cars use the same quiet, responsive motors found in battery electric vehicles.

- Power control units manage energy flow: These smart systems balance power between the fuel cell, battery, and motor for optimal performance.

- Thermal management keeps components cool: Proper cooling ensures fuel cells and batteries operate safely and efficiently under all conditions.

- Hydrogen cars include a small backup battery: This supports acceleration and stores energy from regenerative braking.

- Safety systems protect drivers and passengers: Multiple sensors and shut-off valves prevent leaks and ensure safe operation.

📑 Table of Contents

Introduction to Hydrogen Cars

Imagine filling up your car in just three to five minutes and driving 300 to 400 miles on a single tank—all while emitting nothing but clean water vapor. That’s the promise of hydrogen-powered vehicles, a technology that’s been quietly advancing for decades and is now gaining real momentum. Unlike battery electric vehicles (BEVs) that rely on large, heavy batteries, hydrogen cars generate their own electricity onboard using a chemical reaction between hydrogen and oxygen. This makes them an attractive alternative for drivers who want zero emissions without long charging stops.

Hydrogen cars, also known as fuel cell electric vehicles (FCEVs), are part of a broader shift toward clean transportation. They combine the best of electric driving—smooth acceleration, quiet operation, and zero tailpipe emissions—with the convenience of traditional gasoline vehicles. But how do they actually work? The magic happens inside a network of specialized components, each designed to handle the unique challenges of storing and using hydrogen as a fuel. From the fuel cell stack to the high-pressure tanks, every part plays a critical role in making hydrogen cars safe, efficient, and practical.

The Fuel Cell Stack: The Engine of a Hydrogen Car

Visual guide about Hydrogen Car Components Explained

Image source: engineeringbro.com

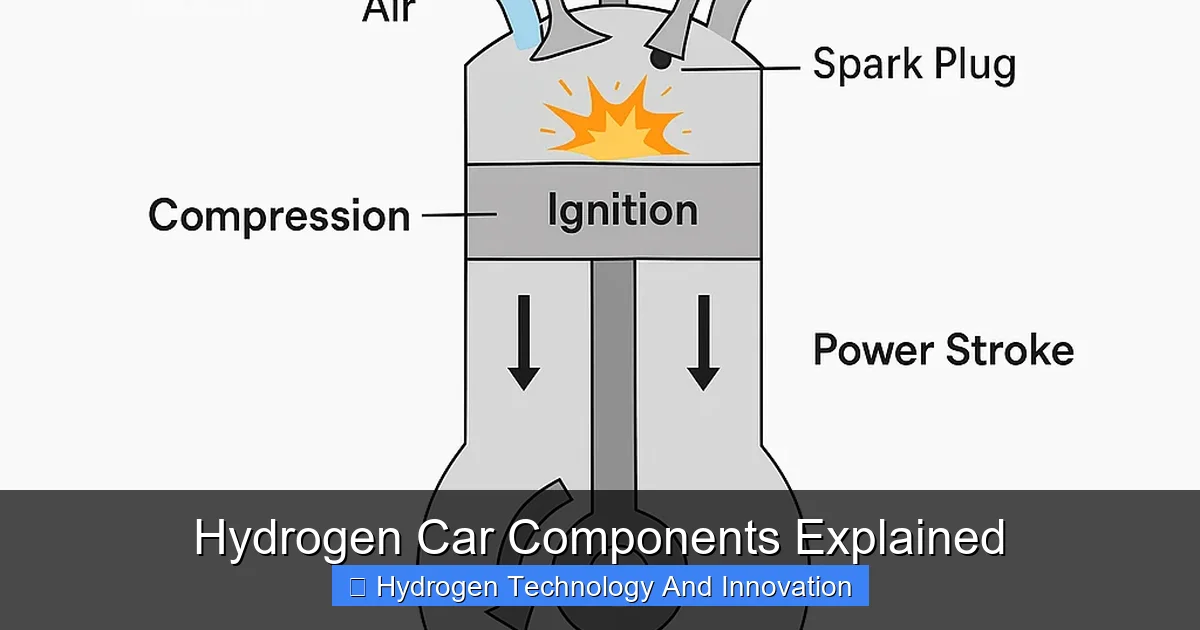

At the core of every hydrogen car is the fuel cell stack—a series of individual fuel cells working together to produce electricity. Think of it as the car’s engine, but instead of burning fuel, it uses a clean electrochemical reaction. Each fuel cell contains an anode, a cathode, and an electrolyte membrane. When hydrogen gas enters the anode, it’s split into protons and electrons. The protons pass through the membrane to the cathode, while the electrons are forced through an external circuit, creating an electric current. At the cathode, oxygen from the air combines with the protons and electrons to form water—the only emission.

How Fuel Cells Generate Electricity

The process starts when hydrogen is fed into the anode side of the fuel cell. A catalyst, usually platinum, helps split the hydrogen molecules into protons and electrons. The protons move through the proton exchange membrane (PEM) to the cathode, but the electrons can’t pass through the membrane. Instead, they travel through an external circuit, generating electricity that powers the car’s motor. This flow of electrons is what we call electric current. Once the electrons reach the cathode, they recombine with the protons and oxygen to form water, which is released as vapor.

This reaction happens silently and efficiently, with no moving parts inside the fuel cell itself. That’s why hydrogen cars are so quiet—there’s no combustion, no pistons, no exhaust noise. The entire process is clean, fast, and reliable, making fuel cells ideal for vehicles.

Types of Fuel Cells Used in Cars

Most hydrogen cars today use Proton Exchange Membrane (PEM) fuel cells. These are lightweight, compact, and can start quickly—even in cold weather. PEM fuel cells operate at relatively low temperatures (around 60–80°C), which makes them well-suited for passenger vehicles. They also respond quickly to changes in power demand, so when you press the accelerator, the car accelerates smoothly and instantly.

Other types of fuel cells, like solid oxide fuel cells (SOFCs), operate at much higher temperatures and are better suited for stationary power generation or large vehicles like buses and trucks. But for everyday cars, PEM fuel cells are the gold standard. They’re durable, efficient, and can last for thousands of hours of operation with proper maintenance.

Efficiency and Performance

One of the biggest advantages of fuel cells is their high efficiency. While internal combustion engines typically convert only 20–30% of fuel energy into motion, fuel cells can achieve 40–60% efficiency. When combined with regenerative braking—which captures energy during deceleration—the overall efficiency can be even higher. This means hydrogen cars can go farther on less fuel, reducing both cost and environmental impact.

For example, the Toyota Mirai, one of the most popular hydrogen cars, has an EPA-estimated range of over 400 miles and can refuel in under five minutes. That’s comparable to many gasoline cars, but with zero emissions. The Hyundai NEXO and Honda Clarity Fuel Cell offer similar performance, proving that hydrogen technology is ready for real-world use.

Hydrogen Storage Tanks: Safely Holding the Fuel

Storing hydrogen safely and efficiently is one of the biggest challenges in hydrogen car design. Unlike gasoline, which is a liquid at room temperature, hydrogen is a gas—and a very light, highly flammable one at that. To make it practical for vehicles, hydrogen must be compressed to extremely high pressures or cooled to a liquid state. Most hydrogen cars use compressed gas storage, with tanks designed to hold hydrogen at 700 bar (about 10,000 psi)—that’s over 30 times the pressure of a typical car tire.

Design and Materials of Hydrogen Tanks

Modern hydrogen tanks are made from advanced composite materials, usually a combination of carbon fiber and polymer liners. The carbon fiber provides incredible strength while keeping the tank lightweight. The inner liner, often made of high-density polyethylene or aluminum, acts as a barrier to prevent hydrogen from escaping. These tanks are rigorously tested to withstand extreme conditions, including crashes, fires, and pressure surges.

For example, the tanks in the Toyota Mirai can survive a direct impact at 50 mph without rupturing. They’re also designed to vent hydrogen safely in the event of a leak, preventing dangerous buildup. In fact, hydrogen is lighter than air, so it disperses quickly if released—unlike gasoline fumes, which can pool near the ground.

Types of Hydrogen Storage

There are three main types of hydrogen storage used in vehicles:

– Type I: Metal tanks, usually steel. These are heavy and rarely used in cars due to weight.

– Type II: Metal tanks with a partial composite wrap. Still too heavy for most passenger vehicles.

– Type III: Aluminum liner with full carbon fiber wrap. Lighter and stronger, used in some early models.

– Type IV: Polymer liner with full carbon fiber wrap. The lightest and most common in modern hydrogen cars.

Type IV tanks are the standard in today’s FCEVs because they offer the best balance of weight, strength, and safety. They allow cars to carry enough hydrogen for long-range driving without adding excessive weight.

Refueling and Range

Refueling a hydrogen car is similar to filling up a gasoline car. Drivers pull up to a hydrogen station, connect a nozzle to the fuel port, and fill the tank in 3–5 minutes. The process is fully automated and safe, with built-in safety checks to prevent overfilling or leaks. Once full, most hydrogen cars can travel 300–400 miles—comparable to many gasoline vehicles.

For instance, the Hyundai NEXO has an EPA-estimated range of 380 miles, while the Toyota Mirai can go over 400 miles on a single tank. This makes hydrogen cars ideal for long-distance travel, especially in areas with limited charging infrastructure.

Electric Motor and Drivetrain

Even though hydrogen cars use fuel cells to generate electricity, they still rely on electric motors to drive the wheels—just like battery electric vehicles. The electric motor is the component that converts electrical energy into mechanical motion, spinning the wheels and propelling the car forward. These motors are incredibly efficient, quiet, and responsive, offering instant torque for smooth acceleration.

How the Electric Motor Works

The electric motor in a hydrogen car is typically a permanent magnet synchronous motor (PMSM), similar to those used in Tesla and other EVs. When electricity from the fuel cell flows into the motor, it creates a magnetic field that interacts with the motor’s rotor, causing it to spin. This rotation is transferred to the wheels through a transmission or direct drive system.

One of the biggest advantages of electric motors is their simplicity. They have far fewer moving parts than internal combustion engines, which means less wear and tear, lower maintenance, and longer life. There’s no need for oil changes, spark plugs, or exhaust systems. Just clean, quiet power.

Regenerative Braking

Hydrogen cars also use regenerative braking to improve efficiency. When you lift off the accelerator or press the brake, the electric motor switches into generator mode, converting the car’s kinetic energy back into electricity. This energy is stored in a small backup battery, which can then be used to assist the fuel cell during acceleration or high-power demands.

For example, when you slow down from 60 mph to a stop, the motor captures energy that would otherwise be lost as heat in the brakes. This not only improves efficiency but also reduces brake wear, saving money on maintenance over time.

Single-Speed Transmission

Most hydrogen cars use a single-speed transmission, similar to many EVs. Because electric motors deliver maximum torque instantly and across a wide range of speeds, there’s no need for multiple gears. This simplifies the drivetrain, reduces weight, and improves reliability. Drivers experience smooth, seamless acceleration without any gear shifts or engine noise.

Power Control Unit and Energy Management

A hydrogen car isn’t just a fuel cell and a motor—it’s a sophisticated energy management system. The power control unit (PCU) acts as the brain of the vehicle, coordinating the flow of electricity between the fuel cell, battery, and motor. It ensures that power is delivered efficiently and safely under all driving conditions.

Role of the Power Control Unit

The PCU includes several key components:

– DC-DC converter: Steps up or steps down voltage to match the needs of different systems.

– Inverter: Converts DC electricity from the fuel cell and battery into AC electricity for the motor.

– Motor controller: Regulates the speed and torque of the electric motor.

– Battery management system (BMS): Monitors the state of charge, temperature, and health of the backup battery.

These components work together to ensure smooth power delivery. For example, during hard acceleration, the PCU might draw extra power from the backup battery to supplement the fuel cell. During cruising, it might reduce power output to save fuel. The system constantly adjusts to match driver input and driving conditions.

Hybrid Architecture: Fuel Cell + Battery

Most hydrogen cars use a hybrid architecture, combining a fuel cell with a small lithium-ion battery. The fuel cell provides steady, continuous power, while the battery handles peak demands like acceleration or climbing hills. This setup improves efficiency and extends the life of the fuel cell by reducing stress during high-load situations.

For example, the Toyota Mirai has a 1.2 kWh battery that supports the fuel cell during startup and acceleration. This battery is charged by the fuel cell and by regenerative braking. It’s not large enough to drive the car on its own, but it plays a crucial role in balancing power and improving responsiveness.

Thermal Management

Hydrogen cars generate heat during operation, especially in the fuel cell and battery. If not managed properly, this heat can reduce efficiency and damage components. That’s why every hydrogen car includes a thermal management system.

This system uses coolant loops, radiators, and fans to keep the fuel cell, battery, and motor within their optimal temperature ranges. For example, the fuel cell operates best between 60–80°C. If it gets too hot, the membrane can dry out and degrade. If it’s too cold, the reaction slows down, reducing power output.

Advanced thermal systems can even pre-condition the fuel cell before startup, ensuring quick and efficient operation in cold weather. This is especially important in regions with harsh winters, where battery performance can suffer.

Safety Systems and Redundancies

Safety is a top priority in hydrogen car design. Because hydrogen is flammable and invisible, manufacturers include multiple layers of protection to prevent leaks, fires, and explosions. These systems are designed to detect problems early and respond automatically to protect drivers and passengers.

Hydrogen Sensors and Leak Detection

Hydrogen cars are equipped with multiple hydrogen sensors placed throughout the fuel system. These sensors continuously monitor for leaks and can detect even tiny concentrations of hydrogen. If a leak is detected, the system can shut off the fuel supply, activate ventilation fans, and alert the driver.

For example, the Hyundai NEXO has hydrogen sensors in the fuel tank, fuel lines, and passenger cabin. If a leak is detected, the car can automatically close valves and open vents to disperse the gas safely.

Shut-Off Valves and Venting Systems

Every hydrogen car has automatic shut-off valves that can isolate the fuel system in an emergency. These valves are triggered by sensors, crash detection systems, or manual switches. They prevent hydrogen from flowing if there’s a leak, crash, or fire.

In addition, hydrogen tanks are equipped with pressure relief devices (PRDs) that vent gas safely if pressure gets too high—such as during a fire. These devices are designed to release hydrogen upward and away from the vehicle, reducing the risk of ignition.

Crash Safety and Structural Design

Hydrogen cars are built with reinforced structures to protect the fuel system in a crash. The tanks are mounted in secure, impact-resistant locations, often behind the rear seats or under the floor. The entire fuel system is designed to survive high-speed collisions without rupturing.

For example, the Toyota Mirai’s hydrogen tanks are surrounded by a protective cage and located away from the crumple zones. In crash tests, the system has performed exceptionally well, with no fuel leaks or fires reported.

Future of Hydrogen Car Components

As hydrogen technology evolves, so do the components that power these vehicles. Researchers and engineers are working to make fuel cells cheaper, more efficient, and longer-lasting. One major focus is reducing or replacing platinum, a rare and expensive catalyst used in fuel cells. New materials like platinum alloys or non-precious metal catalysts could lower costs and increase availability.

Solid-State Hydrogen Storage

Another area of innovation is hydrogen storage. Instead of high-pressure tanks, future cars might use solid-state storage, where hydrogen is absorbed into metal hydrides or carbon nanomaterials. These systems could store more hydrogen in less space and at lower pressures, improving safety and range.

Improved Fuel Cell Durability

Fuel cells degrade over time due to factors like humidity, temperature swings, and impurities in the hydrogen. New membrane materials and better water management systems are being developed to extend fuel cell life. Some prototypes now last over 10,000 hours—enough for more than 15 years of typical driving.

Integration with Renewable Energy

The future of hydrogen cars is closely tied to green hydrogen—hydrogen produced using renewable energy like wind and solar. As electrolysis technology improves and costs fall, green hydrogen could become the standard fuel for FCEVs. This would create a truly zero-emission transportation system, from production to driving.

Conclusion

Hydrogen cars represent a promising path toward clean, sustainable transportation. By combining advanced fuel cells, high-pressure storage, electric motors, and smart energy management, these vehicles offer a compelling alternative to both gasoline and battery electric cars. They deliver long range, quick refueling, and zero emissions—all without the range anxiety or long charging times associated with EVs.

While challenges remain—such as limited refueling infrastructure and the cost of hydrogen production—the technology is advancing rapidly. With continued innovation in components like fuel cells, tanks, and power systems, hydrogen cars could play a major role in the future of mobility. Whether you’re a tech enthusiast, an environmental advocate, or just someone looking for a cleaner way to drive, understanding how hydrogen car components work is the first step toward embracing this exciting technology.

Frequently Asked Questions

How does a hydrogen car produce electricity?

A hydrogen car produces electricity through a fuel cell, where hydrogen and oxygen react to generate power. This process creates only water and heat as byproducts, making it completely clean.

Are hydrogen cars safe in a crash?

Yes, hydrogen cars are designed with multiple safety features, including reinforced tanks, leak sensors, and automatic shut-off valves. They undergo rigorous crash testing and have proven to be very safe.

How long does it take to refuel a hydrogen car?

Refueling a hydrogen car takes about 3 to 5 minutes, similar to filling up a gasoline vehicle. This is much faster than charging a battery electric car.

What is the range of a typical hydrogen car?

Most hydrogen cars have a range of 300 to 400 miles on a single tank, comparable to many gasoline-powered vehicles. Some models, like the Toyota Mirai, can exceed 400 miles.

Do hydrogen cars have batteries?

Yes, hydrogen cars include a small lithium-ion battery to support the fuel cell during acceleration and to store energy from regenerative braking. It’s not used for primary propulsion.

Can hydrogen cars operate in cold weather?

Yes, modern hydrogen cars are designed to start and operate efficiently in cold climates. Advanced thermal management systems help maintain optimal fuel cell performance even in freezing temperatures.