Hydrogen fuel cells are powering a clean energy revolution beyond cars—revolutionizing aviation, shipping, manufacturing, and more. These zero-emission systems offer efficient, scalable power for industries seeking sustainable alternatives to fossil fuels.

Key Takeaways

- Hydrogen fuel cells are expanding beyond vehicles: They’re now being used in aviation, maritime transport, industrial manufacturing, and remote power systems.

- Zero emissions at the point of use: Fuel cells produce only water and heat as byproducts, making them ideal for decarbonizing hard-to-abate sectors.

- High energy density makes them suitable for heavy-duty applications: Unlike batteries, hydrogen can store large amounts of energy without significant weight penalties.

- Industrial adoption is accelerating: Companies like Airbus, Toyota, and Siemens are investing heavily in hydrogen-powered solutions across multiple sectors.

- Challenges remain in infrastructure and cost: Widespread adoption depends on building hydrogen production, storage, and distribution networks.

- Government policies are driving innovation: National hydrogen strategies in the U.S., EU, Japan, and others are funding pilot projects and R&D.

- Hybrid systems are bridging the gap: Combining fuel cells with batteries or renewables improves efficiency and reliability in real-world applications.

📑 Table of Contents

- Introduction: The Quiet Revolution Beyond the Road

- Hydrogen in Aviation: Reaching New Heights with Clean Flight

- Maritime Transport: Sailing Toward a Hydrogen-Powered Future

- Industrial Manufacturing: Powering the Factory of the Future

- Remote and Off-Grid Power: Energy Where It’s Needed Most

- Challenges and the Path Forward

- Conclusion: A Hydrogen-Powered Future Is Closer Than You Think

Introduction: The Quiet Revolution Beyond the Road

When most people think of hydrogen fuel cells, they picture futuristic cars gliding silently down highways, refueling in minutes and emitting nothing but water vapor. That vision isn’t wrong—but it’s only part of the story. While hydrogen-powered vehicles like the Toyota Mirai and Hyundai NEXO have captured headlines, the real transformation is happening far from the automotive world. Across industries that are notoriously difficult to decarbonize—such as aviation, shipping, steel production, and remote power generation—hydrogen fuel cells are emerging as a game-changing technology.

These industries have long relied on fossil fuels because they demand high energy output, long operational hours, and portability. Batteries, while great for light-duty vehicles, often fall short in these areas due to weight, charging time, and energy density limitations. Hydrogen fuel cells, on the other hand, offer a compelling alternative. They generate electricity through an electrochemical reaction between hydrogen and oxygen, producing only water and heat as byproducts. No combustion. No CO₂. Just clean, reliable power.

What makes this shift so exciting is that it’s not just theoretical. Real-world pilots and commercial deployments are already underway. From cargo ships running on hydrogen-electric propulsion to factories using fuel cells to power heavy machinery, the technology is proving its worth in demanding environments. And as green hydrogen—produced using renewable energy—becomes more affordable, the economic case for adoption grows stronger every year.

Hydrogen in Aviation: Reaching New Heights with Clean Flight

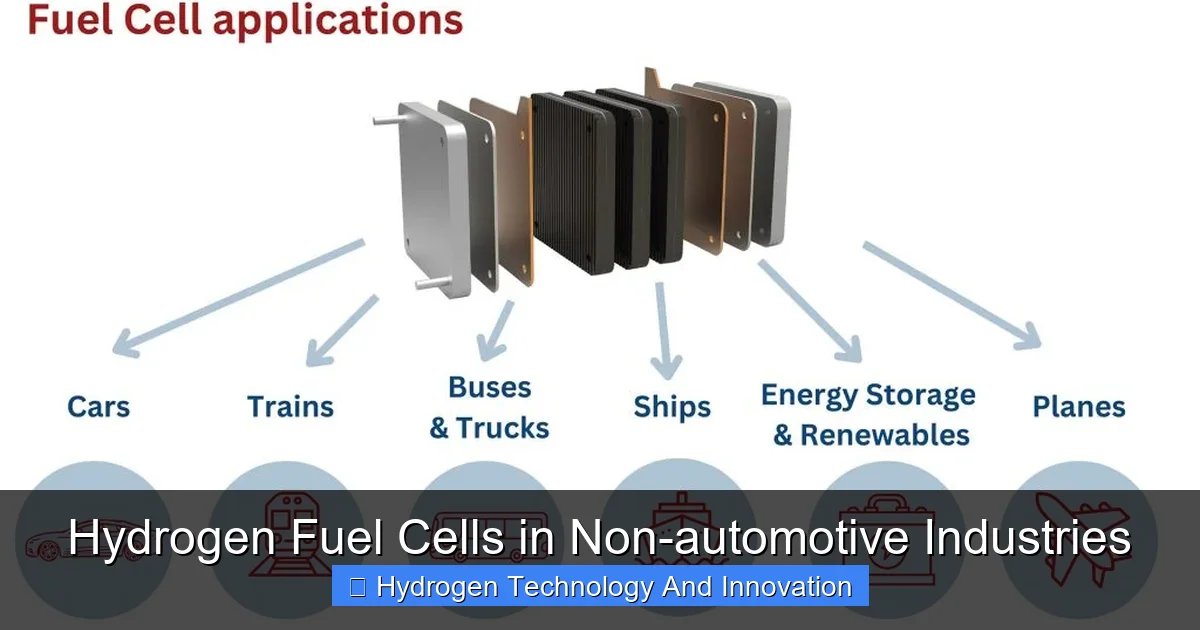

Visual guide about Hydrogen Fuel Cells in Non-automotive Industries

Image source: innovationnewsnetwork.com

The aviation industry accounts for about 2–3% of global CO₂ emissions, and with air travel expected to double by 2050, the pressure to decarbonize is intense. While electric planes are being developed for short-haul flights, they face major hurdles in range and payload. That’s where hydrogen fuel cells come in.

How Hydrogen Powers Aircraft

Hydrogen can be used in two main ways in aviation: as a fuel for combustion in modified jet engines or as a source of electricity in fuel cell systems. The latter is particularly promising for regional and short-haul flights. Fuel cells convert hydrogen into electricity, which then powers electric motors connected to propellers or ducted fans. This setup eliminates direct emissions and reduces noise—a major benefit for airport communities.

Companies like Airbus are leading the charge with their ZEROe program, which aims to launch the world’s first zero-emission commercial aircraft by 2035. Their concepts include turbofan, turboprop, and blended-wing designs, all powered by liquid hydrogen stored in insulated tanks. While challenges remain—such as cryogenic storage and airport refueling infrastructure—the progress is undeniable.

Real-World Examples and Pilots

In 2023, ZeroAvia, a California-based startup, successfully completed test flights of a 19-seat aircraft powered entirely by a hydrogen fuel cell system. The plane flew over 300 miles, demonstrating that the technology is viable for regional air travel. Similarly, the European Union’s Clean Aviation Joint Undertaking has funded multiple hydrogen aviation projects, aiming to integrate the technology into commercial fleets within the next decade.

One practical tip for airports considering hydrogen adoption: start with ground support equipment. Many airports are already replacing diesel-powered baggage tugs and cargo loaders with hydrogen fuel cell versions. These smaller applications help build infrastructure and operational experience before scaling up to aircraft.

Maritime Transport: Sailing Toward a Hydrogen-Powered Future

Shipping is another heavy emitter, responsible for nearly 3% of global greenhouse gas emissions. International regulations from the International Maritime Organization (IMO) are pushing the industry toward net-zero emissions by 2050, and hydrogen is emerging as a key enabler.

Hydrogen vs. Batteries in Maritime Applications

While battery-electric ferries are already in service for short routes—like Norway’s MF Ampere—long-haul shipping requires far more energy. A fully electric container ship would need batteries weighing thousands of tons, drastically reducing cargo capacity. Hydrogen, with its high energy density, offers a more practical solution.

Fuel cells can power ships directly or be used in hybrid systems with batteries for peak loads. Liquid hydrogen or ammonia (a hydrogen carrier) can be stored onboard and used to generate electricity as needed. This allows ships to travel thousands of nautical miles without refueling—something batteries simply can’t match today.

Case Studies: Hydrogen Ships in Action

The Port of Rotterdam is home to the *Hydrogenesis*, a hydrogen-powered inland vessel that began operations in 2022. It uses a 100 kW fuel cell system to transport goods along European waterways, emitting zero pollutants. In Japan, the *Suiso Frontier* became the world’s first liquefied hydrogen carrier, demonstrating the feasibility of transporting hydrogen over long distances.

Another exciting development is the use of hydrogen in port operations. Cranes, forklifts, and tugboats are increasingly being retrofitted with fuel cells. The Port of Los Angeles, for example, has deployed hydrogen fuel cell yard tractors that reduce emissions and improve air quality for nearby communities.

Challenges and Solutions

One major hurdle is the lack of hydrogen refueling infrastructure at ports. However, pilot projects are addressing this. The HySHIP initiative in Europe is developing a hydrogen-powered ferry and a mobile refueling barge to serve multiple ports. Similarly, the U.S. Department of Energy is funding hydrogen hubs that include maritime applications.

A practical tip for shipping companies: consider retrofitting existing vessels with hydrogen-ready systems. This lowers upfront costs and allows for gradual transition as infrastructure develops.

Industrial Manufacturing: Powering the Factory of the Future

Heavy industries like steel, cement, and chemicals are among the largest emitters of CO₂, largely due to their reliance on coal and natural gas. Hydrogen fuel cells offer a way to decarbonize not just the energy supply, but also high-temperature processes.

Hydrogen in Steel Production

Traditional steelmaking uses coking coal to remove oxygen from iron ore—a process that releases vast amounts of CO₂. Hydrogen-based direct reduced iron (H-DRI) replaces coal with hydrogen gas, producing water instead of carbon emissions. While this process uses hydrogen as a chemical reductant, fuel cells can power the electric arc furnaces used to melt the reduced iron.

Companies like SSAB in Sweden have already produced fossil-free steel using hydrogen and are scaling up production. Their HYBRIT project aims to replace all coal-based steelmaking with hydrogen by 2030.

On-Site Power Generation with Fuel Cells

Beyond process heating, many factories use fuel cells for reliable, on-site electricity. Unlike diesel generators, fuel cells operate quietly, produce no particulate matter, and can be integrated with renewable energy systems. For example, a fuel cell can store excess solar power as hydrogen during the day and generate electricity at night.

Siemens Energy has deployed hydrogen fuel cell systems at industrial sites across Europe to provide backup power and grid stabilization. These systems are especially valuable in areas with unreliable grids or strict emissions regulations.

Material Handling and Logistics

Inside factories and warehouses, hydrogen fuel cells are replacing lead-acid batteries in forklifts and pallet jacks. Fuel cell forklifts refuel in minutes—compared to hours for battery swapping—and maintain consistent power output throughout the day. Walmart, Amazon, and BMW have all adopted hydrogen forklifts in select facilities, reporting increased productivity and lower maintenance costs.

A practical tip for manufacturers: start with material handling equipment. The ROI is often quick, and it builds internal expertise for larger applications.

Remote and Off-Grid Power: Energy Where It’s Needed Most

In remote areas—whether Arctic research stations, island communities, or disaster relief zones—access to reliable electricity is a major challenge. Diesel generators are commonly used, but they’re expensive to fuel, polluting, and vulnerable to supply disruptions. Hydrogen fuel cells offer a cleaner, more sustainable alternative.

Microgrids and Renewable Integration

Hydrogen can store excess energy from solar panels or wind turbines. During periods of low generation, fuel cells convert the stored hydrogen back into electricity. This creates a stable microgrid that operates independently of the main power grid.

In Alaska, the village of Igiugig is testing a hybrid system combining solar, wind, and hydrogen fuel cells. The project, supported by the U.S. Department of Energy, aims to eliminate diesel use entirely. Similarly, in Australia, the Horizon Power project in Denham uses hydrogen to store solar energy and power the remote town during nighttime.

Emergency and Backup Power

Fuel cells are also being used for emergency power in hospitals, data centers, and telecommunications towers. Unlike batteries, which degrade over time and require frequent replacement, fuel cells can provide long-duration power with minimal maintenance.

During Hurricane Maria in 2017, Puerto Rico’s power grid was devastated. In the aftermath, fuel cell systems were deployed to power critical facilities. Today, companies like Bloom Energy are offering hydrogen-ready fuel cells that can switch from natural gas to hydrogen as supply becomes available.

Space and Defense Applications

Even beyond Earth, hydrogen fuel cells are proving invaluable. NASA has used them in spacecraft since the 1960s, including the Apollo missions and the Space Shuttle. They provide electricity and drinking water for astronauts. In the military, portable fuel cells are being tested for powering drones, communication systems, and forward operating bases—reducing the need for dangerous fuel convoys.

A practical tip for remote operators: pair fuel cells with renewable sources. This maximizes efficiency and minimizes hydrogen consumption.

Challenges and the Path Forward

Despite the promise, hydrogen fuel cells face significant barriers to widespread adoption in non-automotive sectors.

Cost and Infrastructure

Green hydrogen—produced via electrolysis using renewable electricity—is still more expensive than gray hydrogen (from natural gas) or fossil fuels. Electrolyzers, storage tanks, and fuel cells all contribute to high upfront costs. Additionally, there’s a chicken-and-egg problem: without demand, infrastructure won’t be built; without infrastructure, demand won’t grow.

However, costs are falling rapidly. The International Energy Agency (IEA) predicts that green hydrogen could become cost-competitive by 2030 in many regions, especially with government support.

Storage and Transportation

Hydrogen is the lightest element and requires high pressure or cryogenic temperatures to store efficiently. Liquid hydrogen must be kept at -253°C, which demands specialized tanks and insulation. Ammonia and liquid organic hydrogen carriers (LOHCs) are being explored as safer, more transportable alternatives.

Pipelines are another option. Germany and the Netherlands are expanding hydrogen pipeline networks, while the U.S. is repurposing natural gas pipelines for hydrogen blends.

Policy and Investment

Government support is critical. The U.S. Inflation Reduction Act offers tax credits for clean hydrogen production. The European Union’s REPowerEU plan aims to produce 10 million tons of renewable hydrogen annually by 2030. Japan and South Korea have national hydrogen strategies that include subsidies for fuel cell deployment.

Private investment is also surging. In 2023, over $10 billion was invested in hydrogen projects globally, with a growing share going to non-automotive applications.

Education and Workforce Development

As the industry grows, so does the need for skilled workers. Training programs in hydrogen safety, system maintenance, and integration are essential. Community colleges and technical schools are beginning to offer hydrogen technology courses, preparing the next generation of engineers and technicians.

A practical tip for businesses: partner with research institutions and government programs to access funding and expertise.

Conclusion: A Hydrogen-Powered Future Is Closer Than You Think

Hydrogen fuel cells are no longer a niche technology confined to concept cars and space missions. They are actively reshaping industries that have long been resistant to change. From the skies to the seas, from factory floors to remote outposts, clean hydrogen energy is proving its versatility and reliability.

The transition won’t happen overnight. Challenges in cost, infrastructure, and public awareness remain. But with continued innovation, supportive policies, and cross-industry collaboration, hydrogen can play a central role in achieving global climate goals.

For businesses and policymakers, the message is clear: the time to invest in hydrogen is now. Whether you’re a port operator, manufacturer, or remote community leader, exploring hydrogen fuel cell applications today can position you as a leader in the clean energy economy of tomorrow.

The road to decarbonization is long, but hydrogen is helping us travel it faster—and cleaner.

Frequently Asked Questions

Can hydrogen fuel cells really replace fossil fuels in heavy industries?

Yes, especially in sectors like steel, cement, and chemicals where high heat and process emissions are hard to eliminate. Hydrogen can serve both as a clean fuel and a chemical reductant, enabling near-zero-emission production.

Are hydrogen fuel cells safe for use in aviation and shipping?

Yes, when properly designed and maintained. Modern fuel cells and hydrogen storage systems include multiple safety features, such as leak detection, pressure relief valves, and fire-resistant materials. Regulatory bodies are developing strict standards to ensure safe operation.

How long does it take to refuel a hydrogen-powered ship or plane?

Refueling times vary, but liquid hydrogen can be transferred in hours—much faster than recharging large batteries. Infrastructure improvements are expected to reduce this time further, making hydrogen competitive with conventional fuels.

What’s the difference between gray, blue, and green hydrogen?

Gray hydrogen is made from natural gas and emits CO₂. Blue hydrogen uses carbon capture to reduce emissions. Green hydrogen is produced using renewable energy and electrolysis, making it the cleanest option for fuel cells.

Can existing factories or ships be retrofitted with hydrogen fuel cells?

Yes, in many cases. Retrofitting forklifts, generators, or auxiliary power systems is often cost-effective. Full vessel or plant conversions are more complex but are being piloted in several countries.

Will hydrogen fuel cells ever be cheaper than diesel generators?

They already are in some applications, especially where fuel delivery is expensive or emissions regulations are strict. As green hydrogen production scales up, costs are expected to fall further, making fuel cells increasingly competitive.