Hydrogen fuel cell technology is advancing rapidly, offering cleaner, more efficient energy solutions for transportation, industry, and power generation. With breakthroughs in materials, storage, and cost reduction, hydrogen is becoming a viable alternative to fossil fuels.

Imagine a world where vehicles run silently, emit only water vapor, and refuel in minutes—not hours. That world is no longer science fiction. Thanks to recent innovations in hydrogen fuel cell technology, clean, efficient, and scalable energy solutions are becoming a reality. From city buses to cargo ships, from remote power stations to industrial furnaces, hydrogen is stepping into the spotlight as a key player in the global energy transition.

Hydrogen has long been hailed as a promising clean fuel. When used in a fuel cell, it combines with oxygen to produce electricity, with water as the only byproduct. Unlike batteries, which store energy, fuel cells generate it on demand. This makes them ideal for heavy-duty applications where weight, range, and refueling time matter. But for decades, high costs, limited infrastructure, and reliance on fossil fuels for hydrogen production held the technology back.

Today, that’s changing fast. Scientists, engineers, and policymakers are working together to overcome these barriers. Breakthroughs in materials science, manufacturing techniques, and renewable energy integration are driving down costs and improving performance. At the same time, governments and private companies are investing heavily in hydrogen infrastructure, from production plants to refueling stations. The result? A rapidly evolving landscape where hydrogen fuel cell technology is no longer a niche curiosity—but a cornerstone of a sustainable energy future.

Key Takeaways

- Improved efficiency: New catalysts and membrane designs are boosting fuel cell performance and durability.

- Cost reduction: Manufacturing innovations and scaled production are making hydrogen systems more affordable.

- Green hydrogen growth: Renewable-powered electrolysis is enabling truly carbon-free hydrogen production.

- Transport revolution: Hydrogen-powered trucks, buses, and trains are hitting the roads and rails worldwide.

- Industrial applications: Steel, chemicals, and refining industries are adopting hydrogen to cut emissions.

- Energy storage potential: Hydrogen offers long-duration storage for solar and wind energy, stabilizing the grid.

- Global momentum: Governments and companies are investing billions to build hydrogen infrastructure.

📑 Table of Contents

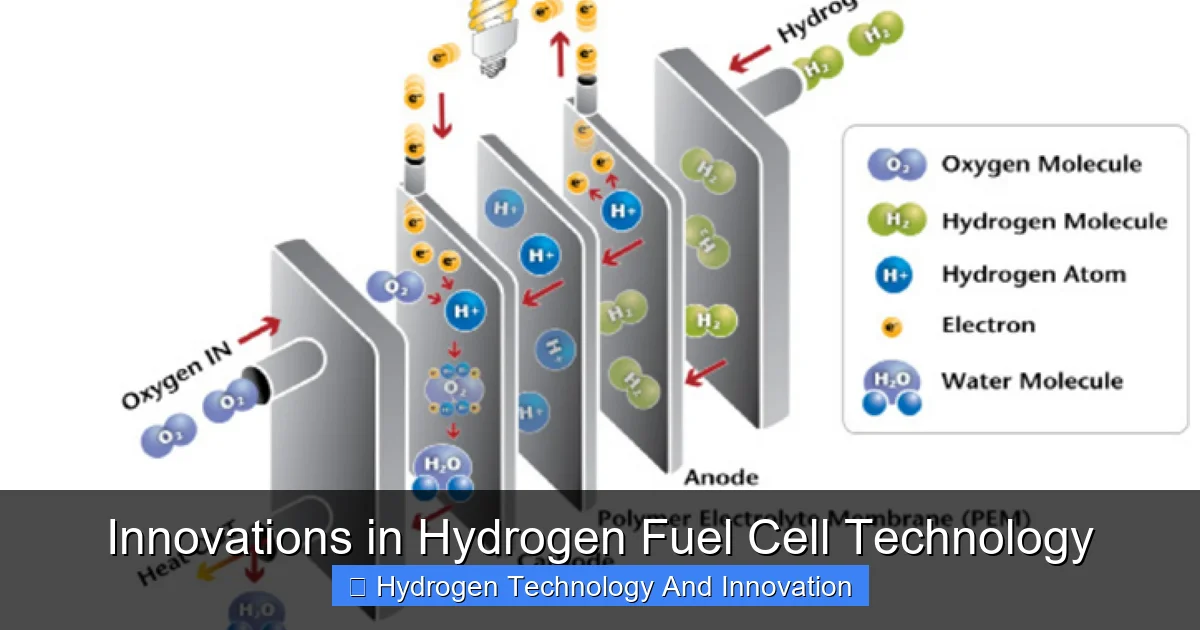

The Science Behind Hydrogen Fuel Cells

At the heart of every hydrogen fuel cell is a simple yet powerful electrochemical reaction. When hydrogen gas (H₂) is fed into the anode side of the cell, a catalyst—usually platinum—splits the hydrogen molecules into protons and electrons. The protons pass through a proton exchange membrane (PEM) to the cathode, while the electrons are forced through an external circuit, creating an electric current. At the cathode, the protons, electrons, and oxygen from the air combine to form water (H₂O)—the only emission.

This process is clean, quiet, and highly efficient. Modern fuel cells can convert 60% or more of the energy in hydrogen into electricity, compared to around 20–30% for internal combustion engines. And because there’s no combustion, there are no harmful pollutants like nitrogen oxides (NOx) or particulate matter.

Types of Fuel Cells

Not all fuel cells are the same. Different designs suit different applications, depending on temperature, efficiency, and fuel flexibility. The most common type used in vehicles and portable power is the PEM fuel cell, which operates at relatively low temperatures (60–80°C) and starts up quickly. This makes it ideal for cars, buses, and backup power systems.

Other types include solid oxide fuel cells (SOFCs), which run at high temperatures (700–1,000°C) and can use a variety of fuels, including natural gas and biogas. SOFCs are often used in stationary power generation, such as in hospitals or data centers. Alkaline fuel cells (AFCs) are another option, historically used in space missions due to their high efficiency, but they’re sensitive to carbon dioxide and require pure hydrogen and oxygen.

Each type has its strengths, but PEM fuel cells remain the focus of most transportation and mobile applications due to their compact size, quick response, and compatibility with pure hydrogen.

How Fuel Cells Differ from Batteries

It’s easy to confuse fuel cells with batteries, but they work in fundamentally different ways. Batteries store energy chemically and release it as electricity when needed. Once depleted, they must be recharged—a process that can take hours. Fuel cells, on the other hand, generate electricity continuously as long as fuel (hydrogen) and oxygen are supplied. They don’t need recharging; they just need refueling.

This makes fuel cells especially useful for long-haul transportation, where downtime is costly. A hydrogen-powered truck can refuel in under 15 minutes and travel over 500 miles—something no current battery-electric truck can match. However, batteries still excel in short-range, stop-and-go applications like city delivery vans or personal cars, where charging infrastructure is widespread.

The future may see hybrid systems that combine both technologies, using batteries for peak power and fuel cells for extended range.

Recent Breakthroughs in Fuel Cell Efficiency

Visual guide about Innovations in Hydrogen Fuel Cell Technology

Image source: climatebiz.com

One of the biggest challenges in hydrogen fuel cell technology has been efficiency—how much of the energy in hydrogen is actually converted into usable electricity. Early fuel cells were hampered by slow reaction rates, membrane degradation, and high catalyst costs. But recent innovations are changing the game.

Advanced Catalysts

Catalysts are essential for speeding up the electrochemical reactions in fuel cells. For decades, platinum has been the go-to material because of its effectiveness. But platinum is rare, expensive, and can degrade over time. Researchers are now developing new catalysts that use less platinum—or none at all.

One promising approach involves platinum alloys, where platinum is combined with metals like cobalt or nickel. These alloys increase the surface area and reactivity of the catalyst, boosting performance while reducing platinum use by up to 50%. Even more exciting are non-precious metal catalysts, such as iron- or cobalt-based compounds, which could eliminate the need for platinum entirely.

For example, scientists at the U.S. Department of Energy’s Los Alamos National Laboratory have developed a carbon-based catalyst that matches platinum’s performance in lab tests. If scaled up, this could dramatically lower the cost of fuel cells.

Next-Generation Membranes

The proton exchange membrane is another critical component. It must allow protons to pass through while blocking electrons and gases. Traditional membranes, like Nafion, work well but can degrade under high heat or low humidity—conditions common in real-world use.

New membrane materials are being engineered to be more durable and efficient. Researchers are experimenting with composite membranes that combine polymers with nanomaterials like graphene or metal-organic frameworks (MOFs). These materials improve proton conductivity and resist degradation, extending the lifespan of fuel cells.

One breakthrough from the University of Delaware involves a self-humidifying membrane that maintains optimal moisture levels without external systems. This not only improves performance but also simplifies the overall design, reducing weight and cost.

Thermal and Water Management

Efficient fuel cells must manage heat and water carefully. Too much heat can dry out the membrane; too much water can flood the electrodes. Engineers are developing smarter thermal management systems that use microchannels, phase-change materials, and adaptive cooling to keep temperatures stable.

Some companies are integrating fuel cells with waste heat recovery systems. For instance, in combined heat and power (CHP) units, the heat generated by the fuel cell is captured and used for heating buildings or industrial processes. This dual-use approach can push overall efficiency above 80%.

Cost Reduction and Scalable Manufacturing

High costs have long been a barrier to widespread adoption of hydrogen fuel cell technology. But thanks to innovations in manufacturing and economies of scale, prices are falling fast.

Automated Production Lines

Traditional fuel cell manufacturing was labor-intensive and slow. Now, companies are adopting automated production lines similar to those used in the automotive and electronics industries. Robots assemble membrane electrode assemblies (MEAs), apply coatings, and test components with precision and speed.

For example, Ballard Power Systems, a leading fuel cell manufacturer, has developed a fully automated production line that can produce thousands of fuel cell stacks per year. This not only reduces labor costs but also improves consistency and quality.

Modular Design and Standardization

Modular designs allow fuel cells to be scaled up or down depending on the application. A single module might power a small generator, while multiple modules can be stacked to run a bus or a ship. Standardizing components—like connectors, cooling systems, and control units—makes it easier to mass-produce and maintain fuel cells.

Companies like Plug Power and Cummins are offering modular fuel cell systems that can be customized for different industries. This flexibility reduces engineering costs and speeds up deployment.

Material Substitution and Recycling

Beyond catalysts, researchers are finding cheaper alternatives for other components. Bipolar plates, which distribute gases and conduct electricity, are often made from graphite—a costly material. New designs use stamped stainless steel or coated metals, which are lighter, cheaper, and easier to manufacture.

Recycling is also becoming a focus. Platinum can be recovered from used fuel cells and reused, reducing the need for mining. Some companies are already offering take-back programs for end-of-life fuel cells, creating a circular economy.

Green Hydrogen: The Key to Clean Energy

For hydrogen fuel cell technology to be truly sustainable, the hydrogen itself must be produced cleanly. Currently, about 95% of hydrogen is made from natural gas through a process called steam methane reforming (SMR), which releases carbon dioxide. This “gray hydrogen” undermines the environmental benefits of fuel cells.

The solution? Green hydrogen—hydrogen produced using renewable energy.

Electrolysis Powered by Renewables

Electrolysis splits water (H₂O) into hydrogen and oxygen using electricity. When that electricity comes from solar, wind, or hydropower, the resulting hydrogen is emissions-free. This is the foundation of the green hydrogen economy.

Recent advances in electrolyzer technology are making this process more efficient and affordable. Proton exchange membrane (PEM) electrolyzers, similar to fuel cells, are compact and responsive, making them ideal for pairing with variable renewable sources. Alkaline electrolyzers are cheaper and more mature, while solid oxide electrolyzers operate at high temperatures and offer higher efficiency.

Countries like Germany, Australia, and Chile are investing heavily in green hydrogen projects. For example, the HyDeal Ambition initiative in Europe aims to produce green hydrogen at scale by 2030, using solar power in sunny regions like Spain and shipping it via pipeline.

Hydrogen Hubs and Infrastructure

To support green hydrogen, a robust infrastructure is needed—production facilities, storage systems, pipelines, and refueling stations. Governments are launching “hydrogen hubs” where industries, energy providers, and transport networks collaborate.

In the U.S., the Department of Energy’s Hydrogen Shot program aims to reduce the cost of clean hydrogen to $1 per kilogram by 2031. Similar initiatives exist in Japan, South Korea, and the European Union.

Pipelines are a key part of the solution. Existing natural gas pipelines can be repurposed to carry hydrogen, though modifications are needed to prevent embrittlement. New hydrogen-specific pipelines are also being built, such as the HyDeploy project in the UK, which blends hydrogen into the natural gas grid.

Applications Across Industries

Hydrogen fuel cell technology is no longer limited to experimental vehicles. It’s being deployed across a wide range of sectors, each with unique needs and opportunities.

Transportation: From Trucks to Trains

Heavy-duty transport is one of the most promising applications. Buses, delivery trucks, and long-haul freight vehicles benefit from hydrogen’s fast refueling and long range.

In California, the Alameda-Contra Costa Transit District (AC Transit) operates a fleet of hydrogen-powered buses that have logged over 5 million miles. In Europe, companies like Hyundai and Toyota are testing hydrogen trucks for cross-border freight.

Trains are another area of growth. In Germany, Alstom’s Coradia iLint is the world’s first hydrogen-powered passenger train, running on non-electrified rail lines. It emits only water and has a range of up to 1,000 kilometers.

Maritime and Aviation

Shipping and aviation are hard to decarbonize due to their high energy demands. Hydrogen offers a solution, especially in the form of liquid hydrogen or ammonia (a hydrogen carrier).

Companies like Maersk and CMA CGM are exploring hydrogen-based fuels for container ships. In aviation, startups like ZeroAvia are developing hydrogen-electric planes for regional flights. Their first commercial route—a 19-seat aircraft flying between London and Rotterdam—is expected to launch in 2025.

Industrial Use and Power Generation

Industries like steel, chemicals, and refining are major emitters. Hydrogen can replace coal and natural gas in high-temperature processes. For example, Swedish company SSAB is using hydrogen instead of coking coal to produce fossil-free steel.

In power generation, fuel cells provide reliable, clean electricity for remote areas, data centers, and emergency backup. Companies like Bloom Energy use solid oxide fuel cells to power hospitals and tech campuses with minimal emissions.

The Road Ahead: Challenges and Opportunities

Despite the progress, challenges remain. Hydrogen is still more expensive than fossil fuels in most markets. Infrastructure is limited, and public awareness is low. Safety concerns—though largely unfounded with proper handling—can slow adoption.

But the momentum is undeniable. With continued innovation, supportive policies, and global collaboration, hydrogen fuel cell technology is poised to play a central role in the clean energy transition.

Investment is pouring in. The global hydrogen market is expected to reach $200 billion by 2030. Countries are setting ambitious targets: the EU aims for 40 gigawatts of electrolyzer capacity by 2030, while Japan plans to import 3 million tons of hydrogen annually.

The key will be integration. Hydrogen won’t replace all energy sources, but it will complement renewables, batteries, and grid upgrades. It’s not a silver bullet—but it’s a powerful tool in the fight against climate change.

Innovations in hydrogen fuel cell technology are not just about cleaner engines or quieter vehicles. They’re about reimagining how we produce, store, and use energy. From the lab to the highway, from the factory to the flight path, hydrogen is proving that a sustainable future isn’t just possible—it’s already here.

Frequently Asked Questions

What is a hydrogen fuel cell?

A hydrogen fuel cell is an electrochemical device that converts hydrogen and oxygen into electricity, water, and heat. It works like a battery but doesn’t need recharging—it generates power as long as fuel is supplied.

How efficient are hydrogen fuel cells?

Modern fuel cells can convert 60% or more of the energy in hydrogen into electricity, making them significantly more efficient than internal combustion engines, which typically achieve 20–30% efficiency.

Is hydrogen fuel safe?

Yes, when handled properly. Hydrogen is flammable, but it’s also lighter than air and disperses quickly. Fuel cells and storage systems are designed with multiple safety features, including leak detection and pressure relief valves.

What is green hydrogen?

Green hydrogen is hydrogen produced using renewable energy, such as wind or solar power, to split water through electrolysis. It’s emissions-free and essential for sustainable fuel cell technology.

Can hydrogen fuel cells power homes?

Yes, stationary fuel cells can provide clean, reliable electricity for homes, businesses, and remote areas. They’re especially useful for backup power and off-grid applications.

How long do hydrogen fuel cells last?

With proper maintenance, fuel cells can last 5,000 to 10,000 hours or more. Advances in materials and design are extending their lifespan, making them viable for long-term use in vehicles and industrial systems.