Hydrogen-powered vehicles are accelerating into the mainstream with cutting-edge fuel cell advancements, expanded infrastructure, and growing support from automakers and governments. From long-haul trucks to passenger cars, hydrogen is proving to be a clean, efficient alternative to fossil fuels—especially for heavy-duty and high-mileage applications.

Key Takeaways

- Fuel cell efficiency is improving: New proton-exchange membrane (PEM) technologies are boosting power output and durability while reducing costs.

- Hydrogen refueling stations are expanding: Countries like Japan, Germany, and South Korea are rapidly building networks to support wider adoption.

- Heavy-duty transport leads the way: Trucks, buses, and trains are among the first to adopt hydrogen due to their long ranges and fast refueling needs.

- Green hydrogen production is scaling up: Renewable-powered electrolysis is making hydrogen cleaner and more sustainable than ever.

- Major automakers are investing heavily: Toyota, Hyundai, and BMW are launching new hydrogen models and partnering on infrastructure.

- Government policies are accelerating adoption: Incentives, subsidies, and emissions regulations are driving investment in hydrogen mobility.

- Challenges remain—but are being addressed: Storage, distribution, and cost barriers are being tackled through innovation and collaboration.

📑 Table of Contents

- Introduction: The Rise of Hydrogen on the Road

- Why Hydrogen Now? A Perfect Storm of Innovation and Need

- Breakthroughs in Fuel Cell Technology

- Expanding Hydrogen Refueling Infrastructure

- Hydrogen in Heavy-Duty and Commercial Transport

- Green Hydrogen: The Clean Fuel of the Future

- Automaker Commitment and New Vehicle Launches

- Government Support and Policy Drivers

- Challenges and the Road Ahead

- Conclusion: A Hydrogen-Powered Future Is Closer Than You Think

Introduction: The Rise of Hydrogen on the Road

Imagine a car that emits nothing but water vapor, refuels in minutes, and travels over 500 miles on a single tank. No, it’s not a sci-fi fantasy—it’s the reality of hydrogen-powered vehicles, and they’re getting closer to everyday use than ever before. While electric vehicles (EVs) have dominated the clean transportation conversation, hydrogen fuel cell vehicles (FCEVs) are quietly making major strides, especially in sectors where battery weight and charging time are limiting factors.

Hydrogen has long been touted as a potential game-changer for clean mobility. Unlike battery-electric vehicles, which rely on heavy lithium-ion packs and can take hours to recharge, hydrogen vehicles generate electricity on board using a fuel cell. This process combines hydrogen from the tank with oxygen from the air, producing power to drive the wheels—and only water as a byproduct. The result? A zero-emission vehicle that feels and drives much like a conventional car, but with none of the tailpipe pollution.

Why Hydrogen Now? A Perfect Storm of Innovation and Need

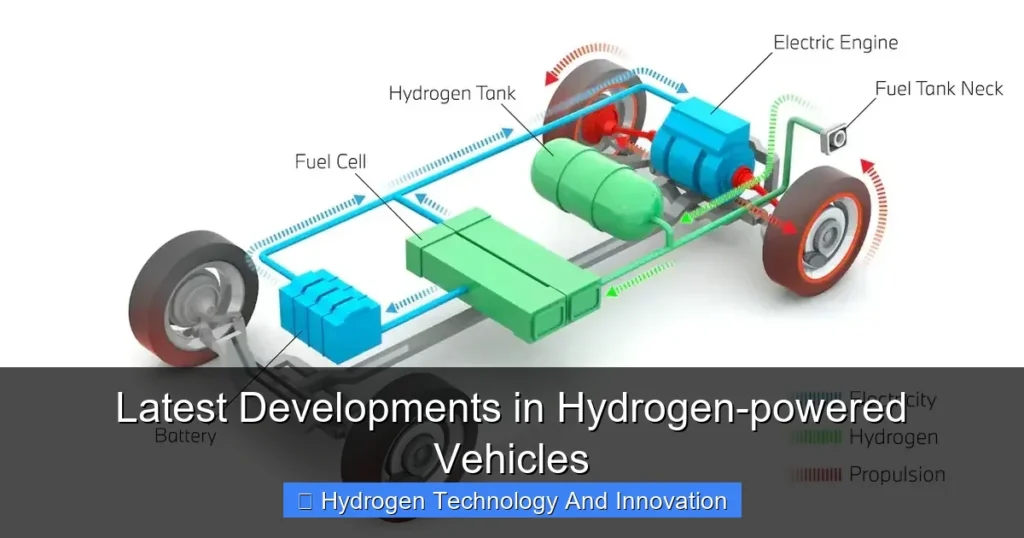

Visual guide about Latest Developments in Hydrogen-powered Vehicles

Image source: static.tnn.in

So why is hydrogen gaining momentum now, after decades of being “the fuel of the future”? The answer lies in a convergence of technological breakthroughs, environmental urgency, and shifting market demands. Climate change is pushing governments and industries to decarbonize rapidly, and transportation remains one of the largest sources of greenhouse gas emissions. While EVs are excellent for urban commuting, they struggle with long-haul freight, aviation, and heavy industry—areas where hydrogen shines.

At the same time, advancements in fuel cell technology have made hydrogen vehicles more efficient, reliable, and affordable. Manufacturers are producing lighter, more durable fuel cells that can withstand extreme temperatures and frequent use. Meanwhile, the cost of producing “green hydrogen”—hydrogen made using renewable energy—is dropping fast, thanks to cheaper solar and wind power and improved electrolysis methods.

Breakthroughs in Fuel Cell Technology

The heart of any hydrogen-powered vehicle is its fuel cell stack—the system that converts hydrogen into electricity. Recent years have seen remarkable progress in this core technology, making FCEVs more practical and competitive.

Next-Generation Proton-Exchange Membrane (PEM) Fuel Cells

Most modern hydrogen vehicles use PEM fuel cells, which operate at relatively low temperatures (around 80°C) and start quickly—ideal for automotive use. The latest PEM designs feature ultra-thin membranes made from advanced polymers that allow protons to pass through more efficiently while blocking electrons, which are then forced through an external circuit to generate electricity.

Companies like Ballard Power Systems and Plug Power have developed new catalysts that reduce the need for expensive platinum, cutting costs without sacrificing performance. Some next-gen fuel cells now use less than 0.2 grams of platinum per kilowatt, down from over 0.5 grams just a decade ago. This not only lowers manufacturing expenses but also reduces reliance on rare materials.

Improved Durability and Cold-Weather Performance

One of the historical drawbacks of fuel cells was their sensitivity to cold weather. Early models struggled to start in freezing temperatures, limiting their appeal in colder climates. But recent innovations have solved this issue. Toyota’s latest Mirai, for example, can start and operate reliably at -30°C, thanks to improved water management and thermal control systems.

Engineers have also enhanced the durability of fuel cell stacks. Modern designs can now last over 25,000 hours of operation—equivalent to driving 600,000 miles—making them suitable for commercial fleets and long-term use. This level of reliability is crucial for convincing fleet operators and consumers to make the switch.

Higher Power Density and Compact Designs

Another major leap is the increase in power density—how much power a fuel cell can produce relative to its size and weight. New stack designs pack more cells into smaller spaces, allowing automakers to integrate fuel cells into a wider range of vehicle types, from compact sedans to large SUVs and trucks.

Hyundai’s NEXO, for instance, features a fuel cell system that’s 30% smaller and 20% lighter than its predecessor, yet delivers more power. This compactness frees up space for passengers and cargo, making hydrogen vehicles more appealing for everyday use.

Expanding Hydrogen Refueling Infrastructure

One of the biggest hurdles to hydrogen vehicle adoption has been the lack of refueling stations. Unlike gasoline or even EV chargers, hydrogen pumps are still rare in most parts of the world. But that’s changing fast.

Global Growth in Refueling Networks

Countries with strong government support are leading the charge. Japan has over 160 hydrogen stations, with plans to reach 320 by 2030. South Korea aims to have 1,200 stations by the same year, supported by a national hydrogen roadmap. In Europe, Germany’s H2 Mobility initiative is building a network of 100 stations, with expansion into France, the Netherlands, and Scandinavia.

The U.S. is also catching up. California currently has around 60 public hydrogen stations—the most in North America—and the state plans to add dozens more. The Inflation Reduction Act includes tax credits for hydrogen production and infrastructure, accelerating investment. Meanwhile, Canada and China are ramping up their own hydrogen station deployments, particularly along major freight corridors.

Mobile and Modular Refueling Solutions

To bridge the gap in areas with limited infrastructure, companies are deploying mobile hydrogen refuelers—trucks equipped with compressors and storage tanks that can deliver fuel to fleets on demand. These units are especially useful for logistics companies testing hydrogen trucks without building permanent stations.

Modular refueling stations are another innovation. These compact, prefabricated units can be installed quickly in urban centers, ports, or industrial zones. They’re often powered by on-site solar or wind, producing green hydrogen locally and reducing transportation emissions.

Standardization and Safety Improvements

As the network grows, standardization is key. Organizations like the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE) have developed safety and performance standards for hydrogen fueling, ensuring compatibility across vehicles and stations.

Modern hydrogen pumps are designed with multiple safety features, including automatic shutoffs, leak detection, and fire suppression systems. Training programs for station operators and emergency responders are also expanding, helping build public confidence in hydrogen as a safe fuel.

Hydrogen in Heavy-Duty and Commercial Transport

While passenger cars get most of the attention, the real sweet spot for hydrogen may be in heavy-duty transportation. Trucks, buses, ships, and even trains are increasingly turning to hydrogen to meet emissions targets and operational demands.

Long-Haul Trucking: The Hydrogen Highway

Battery-electric trucks face significant challenges: heavy batteries reduce payload, long charging times disrupt delivery schedules, and range anxiety limits long-distance routes. Hydrogen solves these issues. A hydrogen-powered semi-truck can travel 500–700 miles on a single fill and refuel in 15–30 minutes—comparable to diesel.

Companies like Hyundai, Nikola, and Toyota are already testing hydrogen trucks in real-world conditions. Hyundai’s XCIENT Fuel Cell trucks have been operating in Switzerland since 2020, with over 5 million kilometers logged. In the U.S., companies like UPS and Amazon are piloting hydrogen delivery vans and freight trucks in California and Texas.

Public Transit and Fleet Vehicles

Cities are also embracing hydrogen buses. London, Cologne, and Aberdeen have deployed fleets of hydrogen-powered double-decker and articulated buses, offering quiet, zero-emission transit with long range and fast refueling. These buses can operate all day on a single tank, making them ideal for urban routes.

Fleet vehicles—like airport shuttles, garbage trucks, and delivery vans—are another strong use case. Because they return to a central depot daily, they can refuel at a single hydrogen station, simplifying infrastructure needs. The Port of Los Angeles, for example, is transitioning its drayage trucks to hydrogen to reduce air pollution in surrounding communities.

Rail and Maritime Applications

Hydrogen isn’t just for roads. Alstom’s Coradia iLint, a hydrogen-powered passenger train, has been running in Germany since 2018, replacing diesel trains on non-electrified lines. It emits only steam and condensed water, offering a clean alternative for regional rail.

In maritime shipping, companies like A.P. Moller-Maersk and Shell are exploring hydrogen and ammonia (a hydrogen carrier) as fuels for cargo ships. While still in early stages, these projects could revolutionize global shipping, one of the hardest sectors to decarbonize.

Green Hydrogen: The Clean Fuel of the Future

Not all hydrogen is created equal. The color-coded system—gray, blue, green—helps distinguish how it’s made. Gray hydrogen, produced from natural gas, still emits CO₂. Blue hydrogen captures and stores those emissions. But green hydrogen, made by splitting water using renewable electricity, is truly zero-emission.

The Rise of Electrolysis

Green hydrogen is produced through electrolysis—a process that uses electricity to split water (H₂O) into hydrogen and oxygen. When that electricity comes from wind, solar, or hydro, the result is a clean, sustainable fuel.

Electrolyzer technology has improved dramatically. Alkaline electrolyzers are mature and cost-effective, while proton-exchange membrane (PEM) electrolyzers offer faster response times and better performance in variable conditions. Solid oxide electrolyzers, still in development, promise even higher efficiency.

Countries like Australia, Chile, and Saudi Arabia are investing billions in green hydrogen projects, aiming to export the fuel globally. The European Union’s REPowerEU plan targets 10 million tons of domestic green hydrogen production by 2030.

On-Site Production and Decentralized Models

To reduce transportation costs and emissions, many hydrogen projects are focusing on on-site production. Solar farms in deserts, wind farms offshore, and even wastewater treatment plants are being equipped with electrolyzers to produce hydrogen locally.

This decentralized approach can power nearby industries, refuel vehicles, or feed into the grid during peak demand. It also reduces the need for long-distance hydrogen pipelines, which are still expensive and complex to build.

Automaker Commitment and New Vehicle Launches

Major car manufacturers are putting serious money and engineering into hydrogen. While some, like Tesla, remain skeptical, others see hydrogen as a critical part of the clean mobility mix.

Toyota: A Longtime Pioneer

Toyota has been a leader in hydrogen technology for over two decades. The Mirai, first launched in 2014, was one of the first mass-produced FCEVs. The second-generation Mirai, released in 2021, offers improved range (over 400 miles), better performance, and a sleeker design. Toyota is also developing hydrogen-powered trucks, forklifts, and even a hydrogen-powered race car.

Hyundai: Scaling Up with the NEXO and XCIENT

Hyundai is another major player. The NEXO SUV, available in the U.S., South Korea, and Europe, boasts a range of over 380 miles and advanced driver-assistance features. But Hyundai’s real focus is on commercial vehicles. The XCIENT Fuel Cell truck is already in service in Europe and the U.S., with plans to deploy thousands more.

BMW and Mercedes: Entering the FCEV Market

BMW has announced plans to launch a hydrogen version of its X5 SUV by 2025, developed in partnership with Toyota. Mercedes-Benz, meanwhile, is testing its GenH2 semi-truck in real-world logistics operations. These moves signal that even luxury automakers see a role for hydrogen in their future lineups.

Startups and Niche Players

Beyond the giants, startups like Riversimple and Hopium are designing lightweight, efficient hydrogen cars aimed at eco-conscious consumers. Hopium’s Machina, a high-performance sedan, promises over 620 miles of range and a futuristic design.

Government Support and Policy Drivers

Government action is accelerating hydrogen adoption. Policies around the world are creating incentives, funding research, and setting ambitious targets.

Subsidies and Tax Credits

In the U.S., the Inflation Reduction Act offers a production tax credit of up to $3 per kilogram for clean hydrogen, making green hydrogen cost-competitive with fossil fuels. Similar incentives exist in the EU, Japan, and Canada.

National Hydrogen Strategies

Over 30 countries have published national hydrogen strategies. Germany’s plan includes €9 billion in funding for hydrogen projects. Japan aims to become a “hydrogen society” by 2050. Australia is positioning itself as a global hydrogen exporter.

Emissions Regulations and Bans on Fossil Fuels

As cities and countries ban internal combustion engines, hydrogen offers a zero-emission alternative for vehicles that can’t easily switch to batteries. California’s Advanced Clean Trucks rule, for example, requires an increasing percentage of zero-emission trucks sold to be electric or hydrogen-powered.

Challenges and the Road Ahead

Despite the progress, hydrogen-powered vehicles still face significant challenges. Cost remains a barrier—both for the vehicles and the fuel. Hydrogen production, even green hydrogen, is currently more expensive than gasoline or electricity per mile. Infrastructure is still sparse outside a few regions. And public awareness is low compared to EVs.

But the momentum is undeniable. With continued innovation, investment, and policy support, hydrogen could become a cornerstone of sustainable transportation—especially for applications where batteries fall short.

Conclusion: A Hydrogen-Powered Future Is Closer Than You Think

The latest developments in hydrogen-powered vehicles show that this technology is no longer a distant dream. From more efficient fuel cells and expanding refueling networks to real-world deployments in trucks, buses, and trains, hydrogen is proving its value as a clean, versatile fuel. While challenges remain, the combined efforts of automakers, governments, and innovators are paving the way for a future where hydrogen plays a key role in decarbonizing transport.

Whether you’re a fleet manager, a policy maker, or just someone who cares about clean air and climate action, now is the time to pay attention. The hydrogen revolution isn’t coming—it’s already here.

Frequently Asked Questions

How do hydrogen-powered vehicles work?

Hydrogen-powered vehicles use a fuel cell to combine hydrogen from the tank with oxygen from the air, generating electricity to power the motor. The only emission is water vapor, making them truly zero-emission.

Are hydrogen cars safe?

Yes, hydrogen cars are designed with multiple safety features, including reinforced tanks, leak detection, and automatic shutoffs. They undergo rigorous testing and meet international safety standards.

How long does it take to refuel a hydrogen car?

Refueling a hydrogen vehicle takes about 3 to 5 minutes—similar to gasoline—making it much faster than charging an electric car.

Where can I refuel a hydrogen car?

Hydrogen refueling stations are currently concentrated in California, Japan, South Korea, and parts of Europe. Networks are expanding rapidly, especially along major freight routes.

Is hydrogen fuel expensive?

Currently, hydrogen fuel is more expensive than gasoline or electricity, but costs are falling as production scales up and green hydrogen becomes more common.

Can hydrogen be used in existing vehicles?

No, hydrogen vehicles require specialized fuel cells and storage systems. However, some research is exploring hydrogen combustion engines as a retrofit option for certain trucks and buses.