Hydrogen car innovation is accelerating, with major advances in fuel cell efficiency, refueling infrastructure, and green hydrogen production. As automakers and governments invest heavily, hydrogen-powered vehicles are poised to play a key role in decarbonizing transport—especially for heavy-duty and long-range applications.

Key Takeaways

- Fuel cell efficiency is improving: New materials and designs are boosting performance while reducing costs, making hydrogen cars more viable.

- Green hydrogen is the game-changer: Produced using renewable energy, it eliminates carbon emissions from the fuel source itself.

- Infrastructure expansion is underway: Countries like Japan, Germany, and South Korea are rapidly building hydrogen refueling networks.

- Heavy-duty transport leads adoption: Trucks, buses, and trains are early adopters due to hydrogen’s high energy density and fast refueling.

- Government support is critical: Policies, subsidies, and international partnerships are accelerating R&D and deployment.

- Challenges remain: High production costs, storage difficulties, and energy losses in conversion need ongoing innovation.

- Consumer models are evolving: Automakers like Toyota, Hyundai, and BMW are refining passenger hydrogen cars for broader markets.

📑 Table of Contents

- The Road Ahead: What’s Next for Hydrogen Car Innovation?

- Breakthroughs in Fuel Cell Technology

- Green Hydrogen: The Clean Fuel Revolution

- Building the Hydrogen Refueling Infrastructure

- Hydrogen in Heavy-Duty and Commercial Transport

- Government Policies and Global Collaboration

- Challenges and How the Industry Is Addressing Them

- The Future of Hydrogen Cars: What to Expect by 2030

- Conclusion: A Hydrogen-Powered Future Is Closer Than You Think

The Road Ahead: What’s Next for Hydrogen Car Innovation?

Imagine pulling up to a fueling station, connecting a nozzle, and refueling your car in under five minutes—just like gasoline. But instead of emitting CO₂, your vehicle releases only water vapor. This isn’t science fiction. It’s the promise of hydrogen-powered cars, and it’s getting closer to reality every year.

Hydrogen cars, also known as fuel cell electric vehicles (FCEVs), use hydrogen gas to generate electricity through a chemical reaction in a fuel cell. This powers an electric motor, offering the zero-emission benefits of battery electric vehicles (BEVs)—but with faster refueling and longer range. While BEVs dominate today’s headlines, hydrogen technology is quietly advancing, especially in niches where batteries fall short.

The momentum is building. Major automakers are investing billions. Countries are rolling out national hydrogen strategies. And breakthroughs in production, storage, and fuel cell design are making hydrogen cars more practical, affordable, and sustainable. So, what’s next for hydrogen car innovation? Let’s explore the key developments shaping the future of this promising technology.

Breakthroughs in Fuel Cell Technology

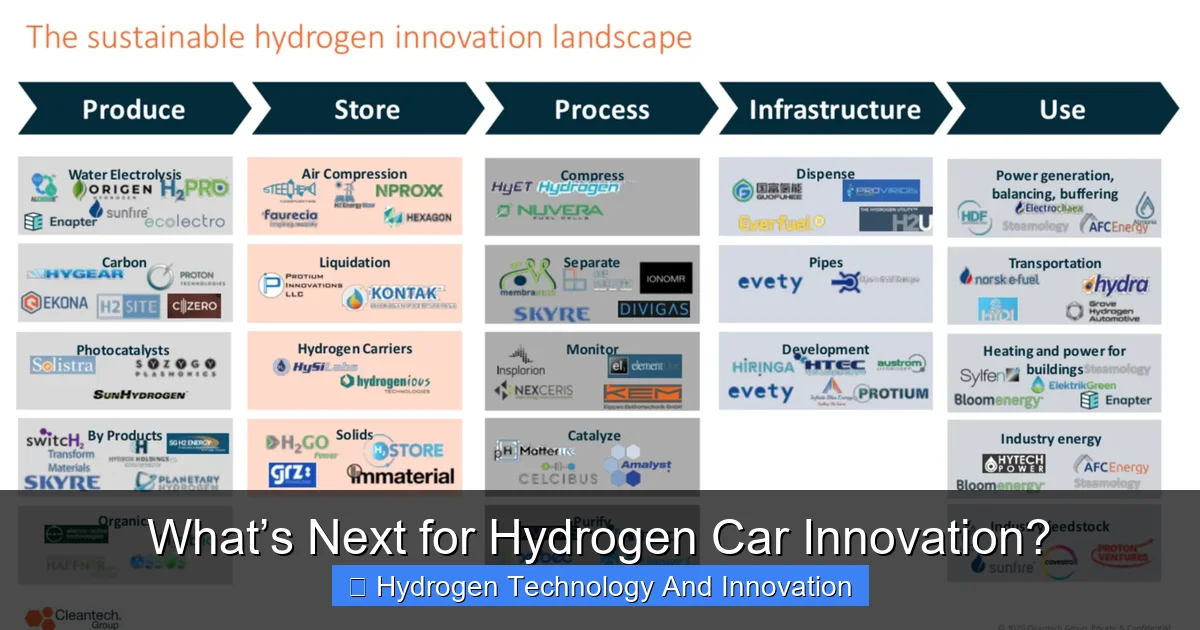

Visual guide about What’s Next for Hydrogen Car Innovation?

Image source: solarimpulse.com

At the heart of every hydrogen car is the fuel cell—a device that converts hydrogen into electricity. For years, fuel cells were expensive, bulky, and inefficient. But recent innovations are changing that.

Next-Generation Membranes and Catalysts

One of the biggest leaps forward is in proton-exchange membrane (PEM) fuel cells. These are the most common type used in vehicles. Researchers are now using advanced materials like graphene and nanostructured catalysts to improve conductivity and durability. For example, a team at the University of California, Berkeley, developed a new catalyst that reduces platinum use by 80%—a major cost saver, since platinum is one of the most expensive components.

Platinum is rare and costly, so reducing its use is critical. Some companies are even experimenting with non-precious metal catalysts, such as iron-nitrogen-carbon compounds. While still in early stages, these alternatives could slash fuel cell costs and make hydrogen cars more competitive with EVs.

Improved Durability and Cold-Weather Performance

Fuel cells have historically struggled in cold climates. Water management is tricky—too much, and the cell floods; too little, and it dries out. But new designs are solving this. Hyundai’s latest NEXO model, for instance, can start in temperatures as low as -30°C, thanks to advanced water circulation systems and thermal management.

Durability is also improving. Early fuel cells lasted around 5,000 hours. Now, manufacturers are targeting 25,000 hours or more—enough for over a decade of daily use. This longevity makes hydrogen cars more appealing for commercial fleets and long-haul transport.

Modular and Scalable Designs

Another trend is modular fuel cell systems. Instead of one large unit, automakers are using smaller, stackable modules. This allows for flexible power output—ideal for everything from compact cars to heavy-duty trucks. Toyota’s “Fuel Cell Module” is a prime example. It’s compact, lightweight, and can be integrated into various vehicle types, from buses to forklifts.

These modular systems also simplify maintenance. If one module fails, it can be replaced without overhauling the entire system. This reduces downtime and repair costs—key factors for fleet operators.

Green Hydrogen: The Clean Fuel Revolution

Hydrogen itself isn’t inherently green. It’s only as clean as the method used to produce it. Currently, over 95% of hydrogen is made from fossil fuels—mainly natural gas—in a process called steam methane reforming. This releases CO₂, undermining the environmental benefits.

But that’s changing fast. The future of hydrogen cars depends on green hydrogen—hydrogen produced using renewable energy.

Electrolysis Powered by Renewables

Green hydrogen is made through electrolysis: splitting water (H₂O) into hydrogen and oxygen using electricity. When that electricity comes from solar, wind, or hydropower, the process emits zero carbon.

Countries with abundant renewable resources are leading the charge. Australia, for example, is investing heavily in solar-powered hydrogen plants. The Asian Renewable Energy Hub in Western Australia aims to produce 1.75 million tons of green hydrogen annually by 2030—enough to power thousands of vehicles and export to Asia.

In Europe, the HyDeal Ambition project plans to build a 67-gigawatt solar-hydrogen complex across Spain, France, and Portugal. Once operational, it could produce green hydrogen at under $1.50 per kilogram—making it competitive with fossil-based hydrogen.

Cost Reduction Through Scale and Innovation

The cost of green hydrogen has dropped by over 60% in the past decade, thanks to cheaper renewables and better electrolyzers. BloombergNEF predicts it could fall below $1 per kilogram by 2030 in ideal locations.

Innovations in electrolyzer technology are also helping. Proton-exchange membrane (PEM) electrolyzers are becoming more efficient and durable. Alkaline electrolyzers are being upgraded with advanced membranes. And solid oxide electrolyzers—still in development—promise even higher efficiency at high temperatures.

As green hydrogen becomes cheaper and more available, the case for hydrogen cars strengthens—especially in regions where renewable energy is abundant.

Building the Hydrogen Refueling Infrastructure

No matter how good the cars are, they won’t succeed without a reliable way to refuel. That’s why building a hydrogen refueling network is one of the biggest challenges—and opportunities—in the industry.

Global Expansion of Refueling Stations

As of 2024, there are over 1,000 hydrogen refueling stations worldwide. While that’s a fraction of EV charging points, the growth is accelerating.

Japan leads with over 160 stations, thanks to strong government support and partnerships between Toyota, Honda, and energy companies. South Korea is close behind, with plans to reach 1,200 stations by 2030. Germany has over 100 stations and aims for 1,000 by 2030 as part of its National Hydrogen Strategy.

In the U.S., California is the hub, with more than 60 stations. The state’s Zero-Emission Vehicle (ZEV) mandate and incentives have driven adoption. The Biden administration’s Inflation Reduction Act also includes $9.5 billion for clean hydrogen, including infrastructure.

Innovative Station Designs and Mobile Refueling

Traditional hydrogen stations are expensive—up to $2–3 million each—due to high-pressure storage and safety systems. But new designs are cutting costs.

Some companies are using on-site electrolysis, producing hydrogen directly at the station using solar or grid power. This eliminates the need for transport, reducing emissions and costs. Others are deploying modular stations that can be scaled up as demand grows.

Mobile refueling is another innovation. Companies like Hyzon and Nel are developing hydrogen trailers that can deliver fuel to remote locations or construction sites. This is especially useful for fleets that operate in areas without fixed stations.

Hydrogen Highways and Corridors

Governments and private companies are creating “hydrogen highways”—dedicated routes with refueling stations every 100–150 miles. The European Union’s Trans-European Transport Network (TEN-T) includes hydrogen corridors for trucks and buses. California’s “Hydrogen Highway Network” connects major cities from San Diego to Sacramento.

These corridors are essential for long-haul transport, where hydrogen’s fast refueling and long range give it an edge over batteries.

Hydrogen in Heavy-Duty and Commercial Transport

While passenger hydrogen cars get the most attention, the real near-term opportunity lies in commercial and heavy-duty vehicles.

Trucks and Logistics

Long-haul trucks are a major source of emissions. Batteries are heavy and take hours to charge, making them impractical for cross-country routes. Hydrogen, on the other hand, offers quick refueling and ranges of 500–800 miles.

Companies like Hyundai, Nikola, and Toyota are developing hydrogen-powered trucks. Hyundai’s XCIENT Fuel Cell truck is already in use in Switzerland, California, and South Korea, with over 500 units deployed. Nikola’s Tre FCEV is being tested by major logistics firms in the U.S.

These trucks can refuel in 15–20 minutes and carry heavy loads—something batteries struggle with. As green hydrogen becomes available, fleets can drastically cut emissions without sacrificing performance.

Buses and Public Transit

Cities are turning to hydrogen buses for cleaner public transit. London, for example, has over 20 hydrogen double-decker buses in service. Aberdeen, Scotland, has one of the largest hydrogen bus fleets in Europe, with 10 vehicles powered by locally produced green hydrogen.

Hydrogen buses are ideal for urban routes because they produce no tailpipe emissions and have longer ranges than battery buses. They also refuel quickly, minimizing downtime.

Trains and Maritime Applications

Hydrogen is also making inroads in rail and shipping. Alstom’s Coradia iLint is a hydrogen-powered train already operating in Germany. It emits only steam and condensed water, making it perfect for non-electrified rail lines.

In maritime transport, companies like Toyota and Shell are testing hydrogen fuel cells for ferries and short-sea shipping. The world’s first hydrogen-powered ferry, the *MF Hydra*, began service in Norway in 2023.

These applications show that hydrogen isn’t just for cars—it’s a versatile solution for decarbonizing transport across multiple sectors.

Government Policies and Global Collaboration

Innovation doesn’t happen in a vacuum. Government support and international cooperation are accelerating hydrogen car development.

National Hydrogen Strategies

Over 40 countries have published hydrogen strategies. These outline goals for production, infrastructure, and adoption. The European Union aims to install 40 gigawatts of electrolyzer capacity by 2030. Japan’s strategy targets 800,000 hydrogen vehicles by 2030. South Korea plans to produce 5 million tons of hydrogen annually by 2040.

These strategies often include funding for R&D, tax incentives, and mandates for zero-emission vehicles. They create a stable environment for investment and innovation.

Public-Private Partnerships

Governments are partnering with automakers, energy companies, and startups to scale hydrogen technology. The U.S. Department of Energy’s “Hydrogen Shot” initiative aims to reduce the cost of clean hydrogen to $1 per kilogram within a decade.

In Germany, the H2 Mobility consortium—backed by Daimler, Shell, and Linde—is building a nationwide refueling network. Similar partnerships exist in France, Canada, and Australia.

These collaborations pool resources, share risks, and speed up deployment.

International Standards and Trade

As hydrogen trade grows, so does the need for standards. The International Organization for Standardization (ISO) and the International Energy Agency (IEA) are developing guidelines for safety, purity, and transport.

Countries are also exploring hydrogen exports. Australia, Chile, and Saudi Arabia are positioning themselves as green hydrogen exporters, shipping it to Asia and Europe. This global trade could lower costs and increase supply.

Challenges and How the Industry Is Addressing Them

Despite the progress, hydrogen cars face real hurdles. Let’s look at the biggest challenges and how innovators are tackling them.

High Production and Distribution Costs

Green hydrogen is still more expensive than fossil-based hydrogen or gasoline. Electrolyzers, storage tanks, and transport infrastructure all add up.

But costs are falling fast. As renewable energy gets cheaper and electrolyzer production scales up, green hydrogen is expected to reach cost parity with fossil fuels by 2030 in many regions. Government subsidies and carbon pricing also help level the playing field.

Energy Loss in Conversion

Hydrogen isn’t the most efficient energy carrier. Converting electricity to hydrogen, then back to electricity in a fuel cell, loses about 30–40% of the original energy. That’s worse than charging a battery directly.

However, in applications where batteries aren’t practical—like long-haul trucks or aviation—hydrogen’s advantages outweigh the losses. And as efficiency improves, the gap is narrowing.

Storage and Safety Concerns

Hydrogen is highly flammable and requires high-pressure tanks or cryogenic storage. This raises safety concerns, though modern tanks are rigorously tested and extremely safe.

New storage methods are emerging. Liquid organic hydrogen carriers (LOHCs) absorb hydrogen like a sponge, making it easier to transport. Metal hydrides and ammonia are also being explored as safer alternatives.

Limited Consumer Awareness

Most people still don’t know much about hydrogen cars. Education and test drives are key. Automakers are partnering with governments to offer public demos and pilot programs.

For example, Toyota’s “Mirai Tour” lets people experience hydrogen driving firsthand. Hyundai offers fleet trials for businesses. These efforts build trust and familiarity.

The Future of Hydrogen Cars: What to Expect by 2030

So, where will hydrogen car innovation be in the next decade?

By 2030, we can expect:

– **More affordable green hydrogen** at or below $2 per kilogram in key markets.

– **Thousands of new refueling stations** across Europe, Asia, and North America.

– **Wider availability of hydrogen passenger cars**, with models from Toyota, Hyundai, BMW, and potentially others.

– **Dominance in heavy-duty transport**, with hydrogen trucks and buses becoming common on highways and city streets.

– **Integration with renewable energy grids**, where excess solar and wind power is used to produce hydrogen, storing energy for later use.

Hydrogen won’t replace battery electric vehicles—but it will complement them. For long-range, high-power, and fast-refueling needs, hydrogen has a clear role to play.

Conclusion: A Hydrogen-Powered Future Is Closer Than You Think

Hydrogen car innovation is no longer a distant dream. It’s happening now. From smarter fuel cells to green hydrogen production, from expanding infrastructure to real-world deployments in trucks and buses, the pieces are falling into place.

Yes, challenges remain. But with continued investment, innovation, and collaboration, hydrogen-powered transport is poised to become a major part of the clean energy transition. Whether you’re a fleet operator, a city planner, or a curious consumer, now is the time to pay attention.

The road ahead is long—but it’s also exciting. And with every mile driven on hydrogen, we move one step closer to a cleaner, quieter, and more sustainable future.

Frequently Asked Questions

Are hydrogen cars really zero-emission?

Yes, hydrogen cars emit only water vapor from the tailpipe. However, the overall environmental impact depends on how the hydrogen is produced. Green hydrogen, made with renewable energy, is truly zero-emission.

How long does it take to refuel a hydrogen car?

Refueling a hydrogen car takes 3–5 minutes—similar to gasoline. This is much faster than charging a battery electric vehicle, making it ideal for long trips and commercial use.

Are hydrogen cars safe?

Yes, hydrogen cars are designed with multiple safety features, including leak detection, pressure relief devices, and strong storage tanks. They undergo rigorous testing and have a strong safety record.

Can I refuel a hydrogen car at home?

Currently, home refueling is rare and expensive. Most hydrogen is dispensed at public stations. However, some companies are developing home electrolyzers, though they’re not yet widely available.

Why aren’t there more hydrogen cars on the road?

Limited refueling stations, high vehicle costs, and low consumer awareness have slowed adoption. But with growing infrastructure and falling hydrogen prices, this is changing rapidly.

Will hydrogen cars replace electric cars?

Not likely. Hydrogen and battery electric vehicles serve different needs. Hydrogen excels in long-range and heavy-duty applications, while batteries are better for short trips and urban driving. Both will coexist in a clean transport future.