Hydrogen fueling stations for commercial vehicles are paving the way for zero-emission heavy-duty transport. With faster refueling, longer range, and growing infrastructure, hydrogen is becoming a practical alternative to diesel for fleets.

Key Takeaways

- Hydrogen fueling stations support zero-emission commercial vehicles like trucks, buses, and delivery vans, helping companies meet sustainability goals.

- Refueling is fast—often under 15 minutes, matching or beating diesel refueling times and minimizing downtime for fleets.

- Green hydrogen, produced using renewable energy, is key to maximizing environmental benefits and reducing carbon footprints.

- Infrastructure is expanding globally, with major investments in the U.S., Europe, and Asia to support growing hydrogen vehicle adoption.

- Government incentives and regulations are accelerating the deployment of hydrogen stations and adoption of fuel cell electric vehicles (FCEVs).

- Challenges remain, including high initial costs and limited station coverage, but innovation and scaling are driving progress.

- Hydrogen complements battery-electric vehicles by offering a solution for long-haul and high-utilization routes where batteries may fall short.

📑 Table of Contents

- Introduction: The Rise of Hydrogen in Commercial Transport

- What Are Hydrogen Fueling Stations?

- The Role of Hydrogen in Decarbonizing Commercial Transport

- Building the Hydrogen Refueling Infrastructure

- Green Hydrogen: The Key to Sustainability

- Government Support and Policy Drivers

- The Future of Hydrogen Fueling for Commercial Vehicles

- Conclusion: A Cleaner Road Ahead

Introduction: The Rise of Hydrogen in Commercial Transport

Imagine a world where big rigs, delivery trucks, and city buses run quietly, emit nothing but water vapor, and refuel as quickly as a diesel engine. That future is no longer a distant dream—it’s being built today with hydrogen fueling stations for commercial vehicles. As the transportation sector faces increasing pressure to cut emissions, hydrogen is emerging as a powerful solution, especially for heavy-duty and long-range applications where battery-electric vehicles (BEVs) face limitations.

Unlike passenger cars, commercial vehicles—such as freight trucks, garbage trucks, and transit buses—require high energy density, long range, and minimal downtime. Hydrogen fuel cell electric vehicles (FCEVs) meet these demands by converting hydrogen gas into electricity on board, powering the vehicle with zero tailpipe emissions. But for FCEVs to succeed, they need a reliable network of hydrogen fueling stations. That’s where infrastructure becomes critical.

What Are Hydrogen Fueling Stations?

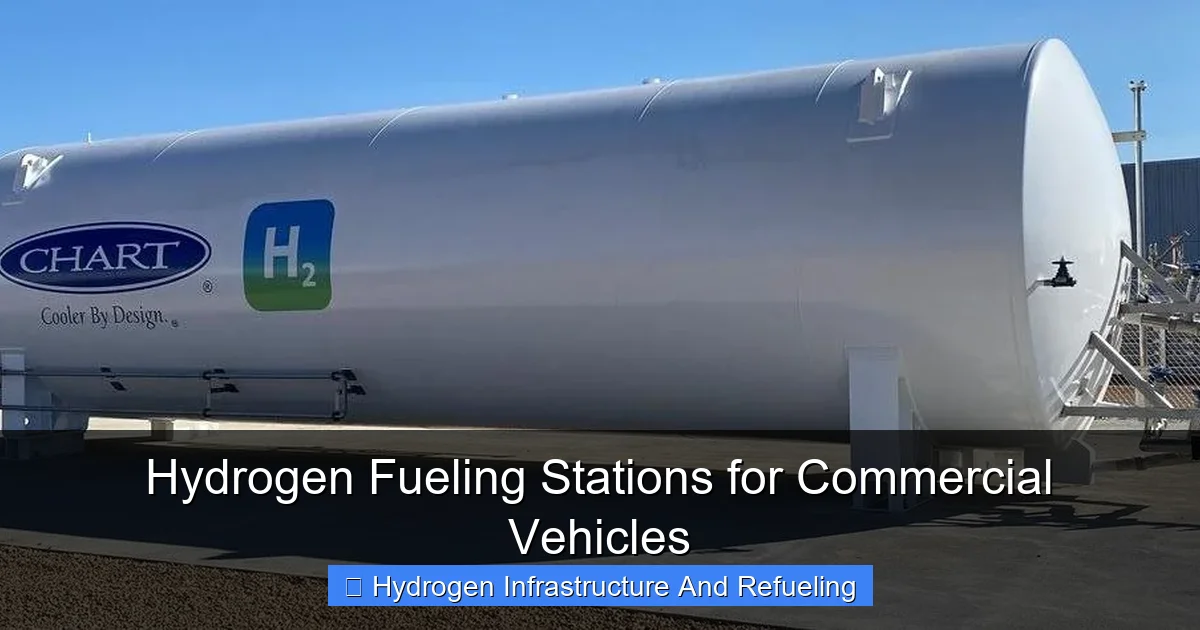

Visual guide about Hydrogen Fueling Stations for Commercial Vehicles

Image source: chartwebstorage.blob.core.windows.net

Hydrogen fueling stations are specialized facilities designed to store, compress, and dispense hydrogen gas to fuel cell vehicles. Think of them as the gas stations of the future—but instead of pumping gasoline or diesel, they deliver clean-burning hydrogen. These stations are essential for the operation of hydrogen-powered commercial vehicles, enabling them to refuel quickly and continue their routes without long charging delays.

How Hydrogen Fueling Stations Work

At a basic level, hydrogen fueling stations operate similarly to traditional gas stations, but with advanced technology to handle a highly flammable and low-density gas. The process begins with hydrogen storage, typically in high-pressure tanks at 350 or 700 bar (5,000 to 10,000 psi). The hydrogen is then compressed and dispensed into the vehicle’s onboard tanks through a specialized nozzle that ensures a secure, leak-free connection.

Most stations use one of two delivery methods: gaseous hydrogen dispensed directly into the vehicle, or liquid hydrogen, which is stored at cryogenic temperatures and vaporized before use. Gaseous hydrogen is more common for light- and medium-duty vehicles, while liquid hydrogen is gaining traction for heavy-duty applications due to its higher energy density.

Types of Hydrogen Fueling Stations

There are several types of hydrogen fueling stations, each suited to different needs:

- Retail stations: Open to the public, often located along highways or in urban centers. Examples include stations operated by companies like Shell, Air Liquide, and Toyota in California and Europe.

- Fleet-dedicated stations: Built specifically for private or commercial fleets, such as delivery companies or municipal transit agencies. These stations are not open to the public and are optimized for high-volume, frequent refueling.

- Mobile refuelers: Trailer-mounted units that can deliver hydrogen to remote locations or support temporary operations. These are useful during the early stages of infrastructure development.

- On-site generation stations: These produce hydrogen on location using electrolysis (splitting water into hydrogen and oxygen) powered by renewable energy. This reduces reliance on hydrogen transport and supports green hydrogen production.

Safety and Regulations

Safety is a top priority in hydrogen fueling. Hydrogen is highly flammable, but it’s also lighter than air, so it disperses quickly in open areas. Modern stations are equipped with multiple safety systems, including leak detectors, automatic shut-off valves, fire suppression systems, and emergency ventilation. Operators must follow strict codes such as NFPA 2 (National Fire Protection Association) and SAE J2601, which govern hydrogen fueling protocols.

Training for station operators and vehicle technicians is essential. Many companies partner with safety organizations to ensure compliance and build public confidence. With proper design and operation, hydrogen fueling stations are as safe—or safer—than conventional fuel stations.

The Role of Hydrogen in Decarbonizing Commercial Transport

The transportation sector accounts for nearly a quarter of global CO₂ emissions, with heavy-duty vehicles contributing a disproportionate share. While battery-electric trucks are gaining ground, they face challenges in weight, charging time, and range—especially for long-haul freight. Hydrogen offers a compelling alternative.

Why Hydrogen for Commercial Vehicles?

Hydrogen fuel cell vehicles (FCEVs) combine the best of electric and traditional vehicles. They run on electricity generated from hydrogen, producing zero tailpipe emissions. But unlike battery-electric vehicles, they don’t require large, heavy batteries. This makes them ideal for heavy-duty applications where every pound counts.

For example, a Class 8 truck powered by hydrogen can travel 300 to 500 miles on a single fill, with refueling taking just 10 to 15 minutes. Compare that to a battery-electric truck, which may need several hours to recharge and carry a battery weighing several tons. For logistics companies focused on efficiency and uptime, hydrogen offers a clear advantage.

Real-World Examples

Several companies are already putting hydrogen-powered commercial vehicles to work:

- Nikola Motor Company: Developing hydrogen-powered semi-trucks like the Nikola Tre, with partnerships with Anheuser-Busch and other major shippers. Their trucks are designed for regional and long-haul routes, with refueling supported by a growing network of stations.

- Hyundai: Deploying XCIENT Fuel Cell trucks in Switzerland, where a fleet of over 40 hydrogen trucks is supported by a dedicated refueling infrastructure. The program has logged millions of miles with zero emissions.

- UPS and Amazon: Both companies are testing hydrogen delivery vans for last-mile logistics. These vehicles offer longer range and faster refueling than battery alternatives, making them ideal for high-frequency delivery routes.

- Los Angeles Metro: Operating hydrogen-powered buses as part of its clean transit initiative. The buses refuel at a dedicated station and serve high-ridership routes with minimal environmental impact.

These examples show that hydrogen is not just a concept—it’s a working solution for real-world commercial operations.

Building the Hydrogen Refueling Infrastructure

For hydrogen to succeed, infrastructure must keep pace with vehicle deployment. That means building more hydrogen fueling stations in strategic locations—along freight corridors, near distribution centers, and in urban hubs. But developing this infrastructure is complex and costly.

Current State of Hydrogen Infrastructure

As of 2024, there are over 1,000 hydrogen fueling stations worldwide, with the majority in Japan, South Korea, Germany, and the United States. California leads the U.S. with more than 60 operational stations, many supporting both passenger and commercial vehicles. Europe is rapidly expanding its network, with countries like Germany and the Netherlands investing heavily in hydrogen corridors.

Despite progress, station density remains low compared to gasoline or electric charging networks. This limits the range and flexibility of hydrogen vehicles, especially for long-haul freight. However, the gap is closing fast.

Key Challenges in Infrastructure Development

Building hydrogen fueling stations comes with several hurdles:

- High capital costs: A single station can cost between $1 million and $3 million, depending on size and technology. This includes storage, compression, dispensers, and safety systems.

- Limited hydrogen supply: Most hydrogen today is produced from natural gas (gray hydrogen), which emits CO₂. Scaling up green hydrogen—produced using renewable energy—is essential but requires investment in electrolyzers and renewable power.

- Regulatory complexity: Permitting and zoning for hydrogen stations can be slow and inconsistent across regions. Streamlining approvals is critical for faster deployment.

- Supply chain constraints: Components like compressors, dispensers, and storage tanks are specialized and often imported, leading to delays and higher costs.

Overcoming the Barriers

Governments and private companies are working together to address these challenges. In the U.S., the Bipartisan Infrastructure Law allocates $8 billion for hydrogen hubs—regional networks of production, storage, and distribution. Similar programs exist in the European Union and Japan.

Private investment is also growing. Companies like Plug Power, Linde, and Air Products are building hydrogen production facilities and fueling stations. Partnerships between automakers, fuel providers, and fleet operators are helping to share costs and accelerate deployment.

One promising model is the “hydrogen corridor”—a chain of fueling stations along major highways. For example, the I-5 corridor in California and the I-70 corridor in the Midwest are being developed to support cross-country hydrogen trucking.

Green Hydrogen: The Key to Sustainability

Not all hydrogen is created equal. The environmental benefits of hydrogen fueling stations depend heavily on how the hydrogen is produced. There are three main types:

- Gray hydrogen: Made from natural gas through steam methane reforming. It’s the cheapest method but emits CO₂.

- Blue hydrogen: Also made from natural gas, but with carbon capture and storage (CCS) to reduce emissions.

- Green hydrogen: Produced by electrolysis using renewable electricity (solar, wind, hydro). It’s emissions-free and ideal for sustainable transport.

For hydrogen to truly decarbonize commercial transport, green hydrogen must dominate the supply chain. While gray and blue hydrogen can serve as transitional fuels, long-term success depends on scaling up renewable-powered production.

The Path to Green Hydrogen

Green hydrogen is still more expensive than gray hydrogen—typically two to three times the cost. But prices are falling as electrolyzer technology improves and renewable energy becomes cheaper. Experts predict green hydrogen could reach cost parity with gray hydrogen by 2030 in many regions.

Several projects are already underway:

- The HyDeal Ambition project in Spain: Aims to produce green hydrogen at €1.50/kg by 2030, using solar power and large-scale electrolysis.

- The NEOM Green Hydrogen Project in Saudi Arabia: A $8.4 billion facility that will produce 650 tons of green hydrogen per day, primarily for export and industrial use.

- The REFHYNE project in Germany: A 10 MW electrolyzer at a refinery, producing green hydrogen for transport and industrial applications.

As green hydrogen becomes more available, hydrogen fueling stations can offer truly zero-emission fuel, making them a cornerstone of sustainable logistics.

Government Support and Policy Drivers

Government policies play a crucial role in accelerating hydrogen infrastructure. Incentives, regulations, and public investment are helping to de-risk early adoption and stimulate private sector growth.

Incentives and Funding Programs

In the U.S., the Inflation Reduction Act (IRA) includes tax credits for clean hydrogen production—up to $3 per kilogram for green hydrogen. The Bipartisan Infrastructure Law funds hydrogen hubs and station deployment. California’s Clean Transportation Program offers rebates for hydrogen fueling infrastructure.

In Europe, the European Green Deal and REPowerEU plan support hydrogen development. The EU has set a target of 10 million tons of domestic renewable hydrogen production and 10 million tons of imports by 2030.

Regulatory Push for Zero-Emission Vehicles

Many regions are implementing regulations that favor zero-emission commercial vehicles. California’s Advanced Clean Trucks (ACT) rule requires manufacturers to sell an increasing percentage of zero-emission trucks starting in 2024. The European Union’s CO₂ standards for heavy-duty vehicles are also pushing fleets toward cleaner options.

These policies create demand for hydrogen vehicles and, by extension, hydrogen fueling stations. As more fleets transition, the business case for station deployment strengthens.

Public-Private Partnerships

Collaboration is key. Governments are partnering with companies to co-fund stations and share risks. For example, the California Energy Commission has awarded grants to companies like FirstElement Fuel and True Zero to expand the state’s hydrogen network.

Similarly, in Japan, the government works closely with Toyota, Honda, and energy companies to build a nationwide hydrogen society. These partnerships help align goals, reduce costs, and speed up deployment.

The Future of Hydrogen Fueling for Commercial Vehicles

The future looks bright for hydrogen fueling stations. As technology improves and costs decline, hydrogen is poised to become a mainstream fuel for commercial transport. But realizing this vision will require continued investment, innovation, and collaboration.

Emerging Trends

Several trends are shaping the future:

- Modular and scalable stations: New designs allow stations to start small and expand as demand grows, reducing upfront costs.

- Integration with renewable energy: Stations powered by on-site solar or wind can produce and dispense green hydrogen, creating closed-loop systems.

- Hydrogen blending in natural gas pipelines: Some regions are testing the injection of hydrogen into existing gas networks, which could eventually supply fueling stations.

- Autonomous refueling: Robotic systems and automated dispensers could reduce labor costs and improve safety.

Long-Term Outlook

By 2030, analysts predict thousands of hydrogen fueling stations will be operational worldwide, with significant growth in North America, Europe, and Asia. Heavy-duty trucking, public transit, and port operations are expected to lead adoption.

While battery-electric vehicles will dominate light-duty and short-haul applications, hydrogen will likely become the preferred solution for long-haul freight, aviation, and shipping. The two technologies will complement each other, forming a diversified clean transport ecosystem.

Tips for Fleets Considering Hydrogen

If you’re a fleet operator thinking about hydrogen, here are some practical tips:

- Start with a pilot program: Test a few hydrogen vehicles on specific routes to evaluate performance and costs.

- Partner with fuel providers: Work with companies that can supply hydrogen and support station development.

- Leverage incentives: Apply for government grants, tax credits, and rebates to reduce upfront costs.

- Plan for infrastructure: Consider on-site generation or mobile refuelers if public stations are not yet available.

- Train your team: Ensure drivers and technicians are trained in hydrogen safety and operations.

Conclusion: A Cleaner Road Ahead

Hydrogen fueling stations for commercial vehicles are more than just a technological advancement—they’re a vital step toward a cleaner, more sustainable transportation future. With the ability to refuel quickly, travel long distances, and produce zero emissions, hydrogen-powered trucks and buses are proving their value in real-world operations.

While challenges remain, the momentum is undeniable. Governments, companies, and communities are investing in the infrastructure needed to support this transition. As green hydrogen becomes more affordable and stations become more widespread, hydrogen will play a central role in decarbonizing freight, logistics, and public transit.

The road ahead is long, but every mile driven on hydrogen brings us closer to a world where commercial transport no longer harms the planet. The future of fueling is here—and it’s powered by hydrogen.

Frequently Asked Questions

How long does it take to refuel a hydrogen commercial vehicle?

Refueling a hydrogen commercial vehicle typically takes 10 to 15 minutes, similar to diesel trucks. This fast turnaround minimizes downtime and keeps fleets moving efficiently.

Are hydrogen fueling stations safe?

Yes, hydrogen fueling stations are designed with multiple safety features, including leak detection, automatic shut-offs, and fire suppression. With proper operation, they are as safe as conventional fuel stations.

Can hydrogen trucks travel as far as diesel trucks?

Yes, hydrogen fuel cell trucks can travel 300 to 500 miles on a single fill, matching or exceeding the range of many diesel trucks. This makes them ideal for long-haul and regional freight.

Where are hydrogen fueling stations located?

Most stations are in California, Europe (especially Germany and the Netherlands), Japan, and South Korea. New stations are being built along major freight corridors and in urban centers.

Is hydrogen fuel expensive?

Currently, hydrogen fuel is more expensive than diesel, but costs are falling. Government incentives and scaling of green hydrogen production are expected to improve affordability by 2030.

Can I use hydrogen fueling stations with my current fleet?

Only vehicles equipped with hydrogen fuel cells can use these stations. If your fleet runs on diesel or batteries, you’ll need to transition to hydrogen-compatible models.