Hydrogen refueling stations are the backbone of the clean transportation revolution, offering fast, efficient, and zero-emission fueling for hydrogen-powered vehicles. These stations combine advanced compression, storage, and dispensing technologies with robust safety and user-friendly designs to support the growing demand for hydrogen mobility.

Key Takeaways

- Modular and scalable designs allow hydrogen refueling stations to adapt to different locations and demand levels, from urban centers to highway corridors.

- On-site hydrogen production using electrolysis reduces transportation costs and supports renewable integration, making stations more sustainable.

- High-pressure storage systems (up to 700 bar) enable fast refueling times comparable to gasoline, typically under 5 minutes for passenger vehicles.

- Advanced safety features such as leak detection, emergency shutdowns, and fire suppression systems ensure safe operation in public and commercial environments.

- User-friendly interfaces with contactless payment, real-time data, and multilingual support improve the customer experience and encourage adoption.

- Integration with renewable energy allows stations to use solar or wind power for hydrogen production, enhancing their environmental benefits.

- Future-ready infrastructure supports both light-duty vehicles and heavy-duty applications like trucks and buses, paving the way for a hydrogen economy.

📑 Table of Contents

Introduction to Hydrogen Refueling Stations

As the world shifts toward cleaner transportation, hydrogen fuel cell vehicles (FCEVs) are emerging as a powerful alternative to battery-electric and internal combustion engine vehicles. Unlike electric vehicles that rely on lengthy charging times, hydrogen-powered cars can be refueled in just a few minutes—similar to filling up at a gas station. But this convenience depends entirely on the availability of reliable, efficient, and safe hydrogen refueling stations.

Hydrogen refueling stations are specialized facilities designed to store, compress, and dispense hydrogen gas to vehicles equipped with fuel cells. These stations are not just scaled-down versions of gas stations; they represent a new kind of infrastructure built around high-pressure systems, advanced safety protocols, and smart technology. Whether located in urban neighborhoods, along highways, or at fleet depots, these stations are critical to making hydrogen mobility practical and widespread.

Core Components of Hydrogen Refueling Stations

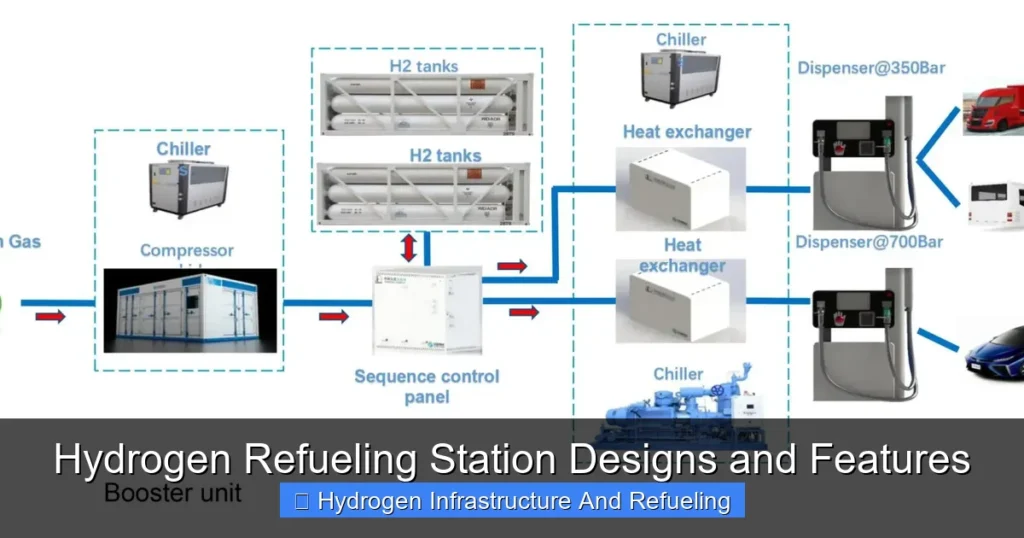

Every hydrogen refueling station is built around a set of core components that work together to deliver hydrogen safely and efficiently. Understanding these components helps clarify how these stations function and why they are engineered with such precision.

Visual guide about Hydrogen Refueling Station Designs and Features

Image source: sollant.com

Hydrogen Production Systems

Hydrogen can be produced either on-site or transported from off-site production facilities. On-site production typically involves electrolysis, where electricity splits water (H₂O) into hydrogen and oxygen. When powered by renewable energy—such as solar or wind—this method produces “green hydrogen,” which has a minimal carbon footprint. Alternatively, hydrogen can be generated via steam methane reforming (SMR), though this method emits CO₂ unless paired with carbon capture.

For example, the H2Station in Copenhagen uses on-site electrolysis powered by wind energy, making it one of the greenest hydrogen stations in Europe. On the other hand, many early stations rely on delivered hydrogen in tube trailers, which is cost-effective for low-demand locations but less sustainable over time.

Compression and Storage

Once produced or delivered, hydrogen must be compressed to high pressures—typically 350 bar for buses and trucks or 700 bar for passenger cars—to maximize storage density and enable fast refueling. High-pressure compressors are essential for this process, and they must be designed to handle hydrogen’s unique properties, such as its low molecular weight and high diffusivity.

Storage tanks are usually made of composite materials to withstand extreme pressures and prevent hydrogen embrittlement, a phenomenon where metals become brittle when exposed to hydrogen. These tanks are often arranged in cascading systems, allowing the station to dispense hydrogen in stages and maintain consistent pressure during refueling.

Dispensing Units and Nozzles

The dispenser is the customer-facing part of the station, where drivers connect their vehicle to refuel. Modern dispensers are equipped with automated controls, digital displays, and secure coupling systems. The nozzle must form a tight seal with the vehicle’s receptacle to prevent leaks, and it often includes thermal sensors to monitor temperature changes during fast fills.

For instance, the Air Liquide H2 Station in California uses a dispenser with a built-in cooling system to manage the temperature rise that occurs during rapid hydrogen compression. This ensures safety and prevents damage to the vehicle’s fuel tank.

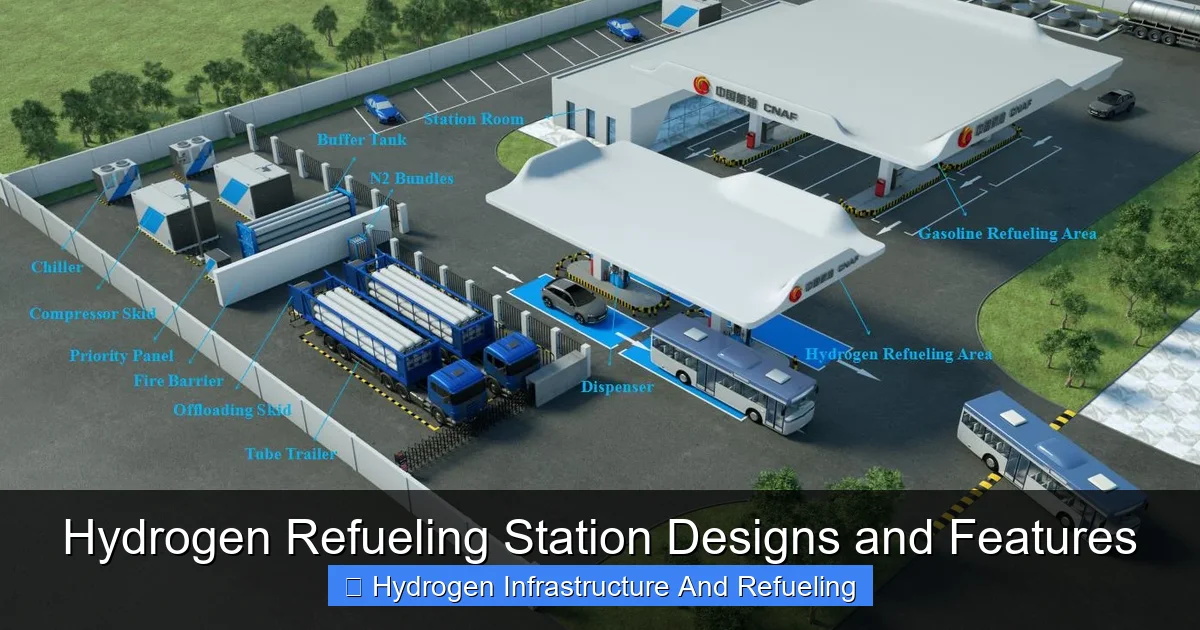

Design Considerations for Hydrogen Stations

Designing a hydrogen refueling station involves more than just installing equipment—it requires careful planning around location, scalability, safety, and user experience. Engineers and architects must balance technical requirements with real-world constraints like space, zoning laws, and public perception.

Modular and Scalable Architecture

One of the most important design trends is modularity. Modular hydrogen stations are built from standardized components that can be easily expanded as demand grows. This approach reduces upfront costs and allows operators to start small—perhaps with a single dispenser—and add more capacity over time.

For example, PowerTap, a subsidiary of Shell, has developed a compact, skid-mounted hydrogen station that can be installed in less than a week. These units are ideal for urban areas where space is limited, and they can be upgraded with additional compressors or storage tanks as fleet adoption increases.

Location and Site Planning

The location of a hydrogen station significantly impacts its success. Ideal sites are near major transportation routes, such as highways or delivery hubs, where hydrogen-powered trucks and buses operate. Urban stations should be easily accessible, well-lit, and integrated into existing fueling networks.

Site planning also involves setback distances from buildings, ventilation requirements, and emergency access routes. In California, for instance, the California Fire Code mandates specific clearance zones around hydrogen equipment to minimize fire risks. These regulations guide the physical layout and help ensure public safety.

Aesthetic and User Experience Design

While functionality is paramount, the visual design of a hydrogen station also matters. A clean, modern appearance can help reduce public anxiety about hydrogen safety and encourage adoption. Many stations now feature sleek canopies, LED lighting, and branding that emphasizes sustainability.

User experience is enhanced through intuitive interfaces. Touchscreen displays guide drivers through the refueling process, while mobile apps allow users to locate stations, check availability, and pay remotely. Some stations even offer real-time hydrogen production data, showing customers how much green energy was used to make their fuel.

Safety Features and Risk Mitigation

Safety is the top priority in hydrogen refueling station design. Although hydrogen is highly flammable, it is also lighter than air and disperses quickly, reducing the risk of accumulation. Still, stations must be equipped with multiple layers of protection to prevent accidents and respond quickly if they occur.

Leak Detection and Monitoring

Hydrogen is invisible and odorless, so detecting leaks requires specialized sensors. Modern stations use a network of hydrogen detectors placed around compressors, storage tanks, and dispensers. These sensors trigger alarms and automatic shutdowns if concentrations exceed safe levels.

For example, the ITM Power refueling station in the UK uses a distributed sensor system that continuously monitors for leaks and sends alerts to a central control room. This proactive approach minimizes downtime and enhances safety.

Emergency Shutdown Systems

In the event of a fire, earthquake, or other emergency, stations must be able to shut down rapidly. Emergency shutdown (ESD) systems cut power to compressors, isolate storage tanks, and stop dispensing operations. These systems can be activated manually by staff or automatically via sensors.

Many stations also include fire suppression systems, such as water deluge or inert gas flooding, to control fires without spreading hydrogen. Fire-resistant barriers and blast walls provide additional protection for critical equipment.

Ventilation and Explosion Prevention

Proper ventilation is essential to prevent hydrogen buildup in enclosed spaces. Stations are designed with open layouts or forced ventilation systems that ensure any leaked gas dissipates quickly. Explosion-proof electrical components are used throughout to eliminate ignition sources.

In Japan, where hydrogen stations are more common, regulations require stations to have multiple ventilation points and regular safety inspections. This has contributed to an excellent safety record, with no major incidents reported in over a decade of operation.

Integration with Renewable Energy and Smart Grids

One of the most exciting developments in hydrogen infrastructure is the integration of refueling stations with renewable energy sources. This not only reduces emissions but also improves energy resilience and cost efficiency.

Solar and Wind-Powered Stations

Stations equipped with on-site solar panels or wind turbines can produce hydrogen using 100% renewable electricity. During periods of low demand, excess energy can be stored as hydrogen, which can later be used for refueling or fed back into the grid.

The HyBalance project in Denmark operates a hydrogen station powered entirely by wind energy. The station produces up to 1,500 kg of hydrogen per day, enough to fuel 50 buses. This closed-loop system demonstrates how hydrogen can support both transportation and grid stability.

Smart Grid Connectivity

Hydrogen stations can act as energy hubs, communicating with the local grid to optimize electricity use. During peak solar generation, excess power can be diverted to electrolyzers. During high demand, the station can reduce consumption or even supply hydrogen to generate electricity via fuel cells.

This bidirectional capability makes hydrogen stations valuable assets in smart grid systems. In Germany, the H2Mobility network is piloting stations that participate in grid-balancing programs, earning revenue while supporting renewable integration.

Future Trends and Innovations

The hydrogen refueling station landscape is evolving rapidly, driven by technological advances, policy support, and growing demand. Several trends are shaping the future of hydrogen infrastructure.

Mobile and Pop-Up Stations

To support early adoption in areas with low vehicle density, mobile hydrogen refueling units are being developed. These trailer-mounted stations can be deployed temporarily at events, construction sites, or fleet depots. They offer flexibility and reduce the need for permanent infrastructure.

For example, HyET Hydrogen has created a mobile refueling unit that can deliver hydrogen to remote locations. These units are ideal for testing hydrogen mobility in new markets without large capital investment.

Hydrogen Blending and Multi-Fuel Stations

Some stations are being designed to dispense multiple fuels, including hydrogen, compressed natural gas (CNG), and electricity. This multi-fuel approach allows operators to serve a broader range of vehicles and transition gradually to hydrogen.

In the Netherlands, the Hynovation station in Rotterdam offers both hydrogen and EV charging, catering to mixed fleets. This hybrid model helps bridge the gap between current and future transportation technologies.

Automation and Remote Monitoring

As stations become more widespread, automation and remote monitoring will play a larger role. Operators can use cloud-based platforms to track performance, schedule maintenance, and respond to alerts from anywhere in the world.

Companies like Ballard Power Systems are developing AI-driven diagnostic tools that predict equipment failures before they occur. This predictive maintenance reduces downtime and extends the lifespan of critical components.

Conclusion

Hydrogen refueling stations are more than just fueling points—they are complex, high-tech systems that represent the future of clean transportation. From modular designs and on-site production to advanced safety features and renewable integration, these stations are built to meet the demands of a rapidly evolving mobility landscape.

As governments and industries invest in hydrogen infrastructure, we can expect to see more stations appearing in cities, along highways, and at logistics hubs. With continued innovation and public support, hydrogen refueling stations will play a central role in decarbonizing transportation and building a sustainable energy future. The road ahead is clear: hydrogen is not just a fuel—it’s a foundation for a cleaner, more resilient world.

Frequently Asked Questions

How long does it take to refuel a hydrogen vehicle?

Refueling a hydrogen vehicle typically takes 3 to 5 minutes, similar to filling up a gasoline car. This fast refueling time is one of the key advantages of hydrogen over battery-electric vehicles, especially for long-distance travel and heavy-duty applications.

Are hydrogen refueling stations safe?

Yes, hydrogen refueling stations are designed with multiple safety systems, including leak detection, emergency shutdowns, and fire suppression. Hydrogen disperses quickly in open air, reducing explosion risks, and stations undergo rigorous testing and certification before operation.

Can hydrogen stations be powered by renewable energy?

Absolutely. Many hydrogen stations use on-site solar or wind power to produce hydrogen via electrolysis, creating a fully renewable fuel cycle. This “green hydrogen” approach significantly reduces carbon emissions compared to fossil-based production methods.

What types of vehicles can use hydrogen refueling stations?

Hydrogen stations support a range of vehicles, including passenger cars, buses, trucks, and even forklifts. Heavy-duty vehicles like long-haul trucks benefit especially from hydrogen’s fast refueling and long range, making it ideal for commercial fleets.

How much does it cost to build a hydrogen refueling station?

Costs vary widely based on size and technology, but a typical station ranges from $1 million to $3 million. Modular and mobile units can be less expensive, while large stations with on-site production may cost more. Government incentives and falling equipment prices are helping reduce costs over time.

Where are hydrogen refueling stations located?

Hydrogen stations are currently concentrated in regions with strong policy support, such as California, Japan, South Korea, and parts of Europe. However, networks are expanding globally, with new stations planned in the U.S., Canada, Germany, and China to support growing FCEV adoption.