Hydrogen refueling stations are emerging as a key part of the clean energy transition, offering zero-emission fuel for vehicles. While they promise reduced greenhouse gas emissions, their environmental footprint depends heavily on how the hydrogen is produced and distributed.

Key Takeaways

- Hydrogen refueling stations support zero-emission vehicles: They enable fuel cell electric vehicles (FCEVs) to run on clean hydrogen, emitting only water vapor.

- Environmental impact varies by hydrogen source: “Green hydrogen” made with renewable energy has minimal emissions, while “gray hydrogen” from fossil fuels can increase carbon output.

- Station infrastructure requires significant energy and resources: Building and operating stations involves energy-intensive processes, including compression, storage, and transportation.

- Location and scalability matter: Strategic placement near renewable energy sources and transportation hubs maximizes environmental benefits.

- Lifecycle emissions must be considered: A full assessment includes production, distribution, and end-use to evaluate true sustainability.

- Policy and innovation drive progress: Government incentives and technological advances are accelerating the adoption of cleaner hydrogen infrastructure.

- Public awareness and education are crucial: Understanding how hydrogen stations work helps consumers and policymakers support sustainable choices.

📑 Table of Contents

- Introduction: The Rise of Hydrogen as a Clean Fuel

- How Hydrogen Refueling Stations Work

- Environmental Impact of Hydrogen Production

- Energy Use and Emissions from Station Operations

- Land Use, Materials, and Infrastructure Challenges

- Comparing Hydrogen Stations to Other Fueling Options

- The Role of Policy, Innovation, and Public Awareness

- Conclusion: A Clean Future with Hydrogen?

Introduction: The Rise of Hydrogen as a Clean Fuel

The world is racing to cut carbon emissions and combat climate change, and transportation is a major focus. While electric vehicles (EVs) charged by batteries have dominated the conversation, another clean technology is gaining momentum: hydrogen fuel cell vehicles (FCEVs). These vehicles run on hydrogen gas and emit only water vapor—no tailpipe pollution. But for FCEVs to become mainstream, they need a reliable network of hydrogen refueling stations. Just like gas stations serve traditional cars, hydrogen stations are the backbone of this emerging ecosystem.

Hydrogen refueling stations are more than just pumps—they’re complex systems that store, compress, and dispense hydrogen safely and efficiently. As countries like Japan, Germany, and the United States invest in hydrogen infrastructure, questions about their environmental impact are growing. Are these stations truly green? Do they help reduce emissions, or do they create new environmental challenges? The answer isn’t black and white. It depends on how the hydrogen is made, how it’s transported, and how the stations are powered. In this article, we’ll explore the environmental footprint of hydrogen refueling stations, from production to pump, and what it means for a sustainable future.

How Hydrogen Refueling Stations Work

To understand the environmental impact of hydrogen refueling stations, it helps to know how they function. These stations are designed to deliver high-pressure hydrogen gas to vehicles in minutes—similar to filling up a gasoline car. But the process behind the scenes is far more complex than it appears.

Visual guide about Hydrogen Refueling Stations and Their Environmental Impact

Image source: sustainabletruckvan.com

Hydrogen Production: The First Step

The journey begins with hydrogen production. Hydrogen is the most abundant element in the universe, but it doesn’t exist freely in nature. It must be extracted from compounds like water (H₂O) or natural gas (CH₄). The method used determines the environmental impact. Currently, most hydrogen is produced through steam methane reforming (SMR), which uses natural gas and releases carbon dioxide. This is known as “gray hydrogen.” A cleaner alternative is electrolysis, where electricity splits water into hydrogen and oxygen. When powered by renewable energy like wind or solar, this produces “green hydrogen” with near-zero emissions.

Compression and Storage

Once produced, hydrogen must be compressed to high pressures—typically 350 to 700 bar—so it can be stored in vehicle tanks. Compression is energy-intensive and often relies on electricity, which may come from fossil fuels unless the grid is clean. Hydrogen is also stored on-site at refueling stations in high-strength tanks made of composite materials. These tanks must withstand extreme pressures and are designed for safety, but their production involves resource-intensive manufacturing.

Dispensing and Safety Systems

When a vehicle arrives, the station dispenses hydrogen through a specialized nozzle that connects to the car’s tank. The process is fast—usually under five minutes—and automated for safety. Stations are equipped with sensors, leak detectors, and emergency shutdown systems to prevent accidents. Ventilation systems ensure any escaped hydrogen disperses quickly, as hydrogen is lighter than air and non-toxic. While safe when managed properly, the infrastructure requires careful engineering and regular maintenance.

On-Site vs. Delivered Hydrogen

Some stations produce hydrogen on-site using electrolyzers, while others receive it via truck or pipeline. On-site production reduces transportation emissions but requires a reliable source of clean electricity. Delivered hydrogen may travel long distances, increasing the carbon footprint unless transported efficiently. For example, liquid hydrogen is more compact but requires cryogenic temperatures, adding energy costs. The choice between on-site and delivered hydrogen affects both cost and environmental performance.

Environmental Impact of Hydrogen Production

The biggest factor in the environmental impact of hydrogen refueling stations is how the hydrogen is made. Not all hydrogen is created equal, and the source of energy used in production makes a huge difference.

Gray, Blue, and Green Hydrogen: What’s the Difference?

Hydrogen is often categorized by color based on its production method:

- Gray hydrogen: Made from natural gas via SMR, emitting CO₂. Accounts for about 95% of global hydrogen production.

- Blue hydrogen: Also from natural gas, but with carbon capture and storage (CCS) to reduce emissions. Still relies on fossil fuels but cuts CO₂ output by 50–90%.

- Green hydrogen: Produced via electrolysis using renewable electricity. Zero direct emissions and the most sustainable option.

Currently, most hydrogen refueling stations use gray or blue hydrogen due to cost and availability. But as renewable energy becomes cheaper and more widespread, green hydrogen is expected to grow. For example, countries like Iceland and Norway are already using geothermal and hydroelectric power to produce green hydrogen locally.

Carbon Footprint of Different Production Methods

The carbon intensity of hydrogen varies widely. Gray hydrogen emits about 10–12 kg of CO₂ per kg of hydrogen. Blue hydrogen reduces this to 1–3 kg with effective CCS. Green hydrogen, when powered by wind or solar, can be below 1 kg CO₂/kg H₂—and even near zero with optimized systems. This means that a hydrogen refueling station using green hydrogen has a far lower environmental impact than one relying on fossil-based sources.

Water Usage and Resource Consumption

Electrolysis requires pure water, and producing 1 kg of hydrogen needs about 9 liters of water. While this may seem small, scaling up green hydrogen production could strain local water supplies in arid regions. Additionally, electrolyzers use rare materials like platinum and iridium, which have environmental and ethical concerns related to mining. Recycling and material efficiency are key to reducing these impacts.

Energy Use and Emissions from Station Operations

Beyond production, the operation of hydrogen refueling stations contributes to their environmental footprint. From compression to dispensing, every step uses energy and generates emissions.

Electricity Demand for Compression and Cooling

Compressing hydrogen to high pressures consumes significant electricity—up to 10–15% of the energy content of the hydrogen itself. If the electricity comes from coal or natural gas, this adds to the station’s carbon footprint. Some stations also use cooling systems to manage temperature during refueling, adding to energy use. Stations powered by on-site solar panels or connected to renewable grids can minimize these emissions.

Transportation Emissions

When hydrogen is delivered by truck, the transportation adds emissions. A study by the National Renewable Energy Laboratory (NREL) found that transporting hydrogen by tube trailer over 100 miles can add 0.5–1 kg CO₂ per kg of hydrogen. Pipeline transport is more efficient but requires major infrastructure investment. On-site production avoids transportation emissions but depends on local renewable energy availability.

Lifecycle Analysis: A Full Picture

To truly assess environmental impact, we need a lifecycle analysis (LCA) that includes production, transportation, station construction, operation, and end-use. A 2022 study published in Nature Energy found that FCEVs using green hydrogen can reduce lifecycle emissions by 60–70% compared to gasoline vehicles. However, FCEVs using gray hydrogen may only achieve a 20–30% reduction—and in some cases, could be worse than efficient hybrids. This highlights the importance of clean hydrogen sources.

Land Use, Materials, and Infrastructure Challenges

Building hydrogen refueling stations isn’t just about energy—it involves land, materials, and long-term sustainability.

Land and Urban Planning

Hydrogen stations require more space than gasoline pumps due to safety buffers and storage tanks. In cities, this can be a challenge. Some stations are co-located with existing gas stations, while others are built in industrial zones. Strategic placement near highways, transit hubs, or renewable energy sites can maximize efficiency and reduce environmental disruption.

Construction Materials and Waste

Stations use steel, concrete, and composite materials, all of which have environmental costs. Manufacturing these materials emits CO₂, and end-of-life disposal must be managed. Recycling programs for tanks and equipment are still developing. Modular station designs and reusable components can help reduce waste.

Safety and Environmental Risks

Hydrogen is flammable and requires careful handling. While modern stations are designed with multiple safety layers, accidents—though rare—can have environmental consequences. For example, a hydrogen leak could lead to fire or explosion if ignited. Proper siting, ventilation, and monitoring systems are essential to prevent incidents.

Comparing Hydrogen Stations to Other Fueling Options

To evaluate the environmental impact of hydrogen refueling stations, it’s helpful to compare them to alternatives like gasoline pumps and EV charging stations.

Hydrogen vs. Gasoline

Gasoline vehicles emit about 2.3 kg of CO₂ per liter burned. Over a vehicle’s lifetime, this adds up to tens of tons of emissions. Hydrogen FCEVs emit only water, but the upstream emissions from hydrogen production matter. With green hydrogen, FCEVs are far cleaner. With gray hydrogen, the advantage shrinks.

Hydrogen vs. Battery Electric Vehicles (BEVs)

BEVs charged with renewable electricity have very low lifecycle emissions. However, hydrogen has advantages in certain applications: long-haul trucking, aviation, and heavy industry, where batteries are too heavy or slow to charge. For passenger cars, BEVs are generally more energy-efficient—converting about 77% of grid energy to motion, compared to 25–35% for FCEVs due to production and conversion losses.

Complementary, Not Competitive

Rather than replacing EVs, hydrogen stations may complement them. In regions with abundant renewable energy, green hydrogen can store excess power and fuel vehicles when needed. This creates a more flexible and resilient energy system.

The Role of Policy, Innovation, and Public Awareness

The future of hydrogen refueling stations depends on more than technology—it requires supportive policies, innovation, and public engagement.

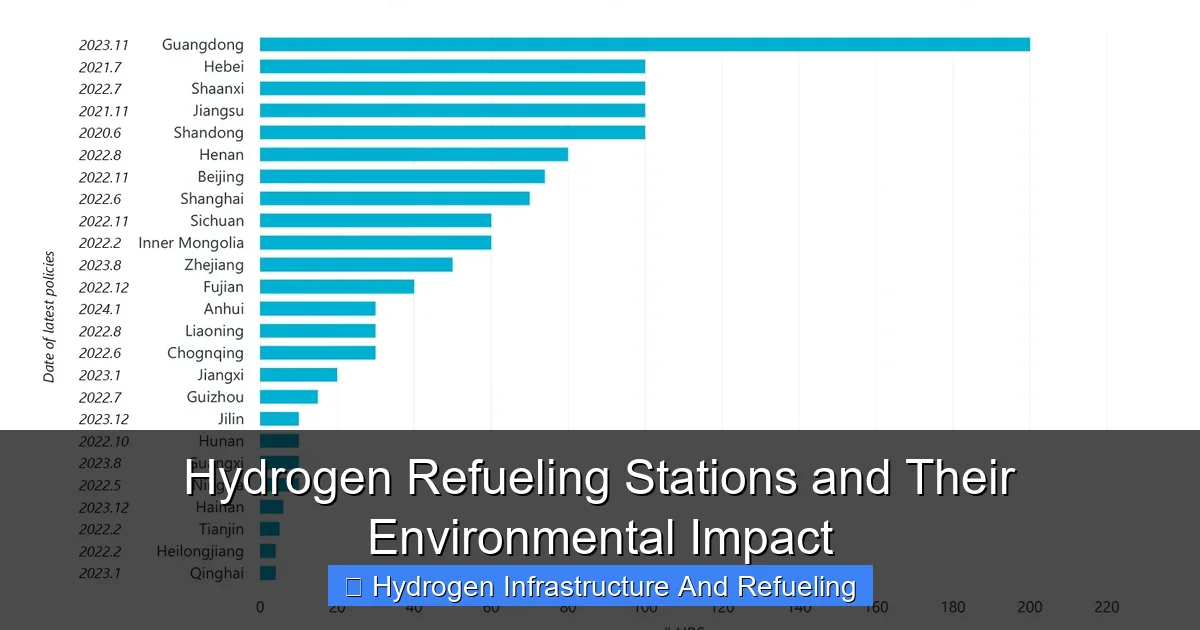

Government Incentives and Regulations

Countries like Germany, Japan, and South Korea have national hydrogen strategies with funding for infrastructure. The U.S. Inflation Reduction Act includes tax credits for clean hydrogen production. These policies help lower costs and encourage investment. Regulations on emissions and safety standards also ensure stations are built and operated responsibly.

Technological Advancements

Innovations are improving efficiency and reducing costs. New electrolyzers use less rare material, and solid-state hydrogen storage could make transportation safer. AI and smart grids can optimize station operations and energy use. As technology advances, the environmental footprint of hydrogen stations will shrink.

Public Education and Acceptance

Many people are unfamiliar with hydrogen vehicles and stations. Misconceptions about safety—fueled by historical events like the Hindenburg—still linger. Clear communication about how modern systems work, their benefits, and their safety record is essential. Public demonstrations, pilot programs, and educational campaigns can build trust.

Conclusion: A Clean Future with Hydrogen?

Hydrogen refueling stations hold great promise for a low-carbon transportation future. When powered by renewable energy, they enable zero-emission travel with fast refueling and long range—ideal for trucks, buses, and remote areas. But their environmental impact isn’t automatic. It depends on how the hydrogen is produced, how the stations are powered, and how the infrastructure is managed.

The path forward is clear: prioritize green hydrogen, invest in clean energy, and build stations strategically. With the right policies, technology, and public support, hydrogen refueling stations can play a vital role in reducing emissions and creating a sustainable transportation system. The journey is just beginning, but the potential is enormous.

Frequently Asked Questions

Are hydrogen refueling stations safe?

Yes, modern hydrogen refueling stations are designed with multiple safety features, including leak detectors, automatic shutoffs, and ventilation systems. Hydrogen is lighter than air and disperses quickly, reducing fire risk. Incidents are rare, and safety standards are continuously improving.

How long does it take to refuel a hydrogen vehicle?

Refueling a hydrogen vehicle takes about 3 to 5 minutes, similar to gasoline. This is much faster than charging a battery electric vehicle, making hydrogen ideal for long trips and commercial fleets.

Can hydrogen stations be powered by renewable energy?

Yes, many new stations are integrating solar panels or sourcing electricity from renewable grids. On-site electrolyzers can produce green hydrogen using wind or solar power, minimizing emissions.

What happens to hydrogen stations at the end of their life?

Stations can be decommissioned and materials recycled. Tanks, compressors, and other components are increasingly designed for reuse or recycling, reducing waste and environmental impact.

Why aren’t there more hydrogen refueling stations?

High costs, limited vehicle availability, and the need for clean hydrogen production have slowed adoption. However, government funding and technological advances are accelerating deployment in key regions.

Is hydrogen better than batteries for electric vehicles?

It depends on the use case. Batteries are more efficient for passenger cars, while hydrogen excels in heavy-duty transport and long-range applications. Both technologies can coexist in a clean energy future.