You might have heard that hydrogen fuel is the clean energy solution of the future. But if it’s so promising, why isn’t it everywhere yet?

The truth is, producing hydrogen fuel comes with many tough challenges that affect its cost, safety, and availability. From expensive production methods to tricky storage and transport issues, these obstacles are slowing down hydrogen’s rise as a mainstream energy source.

If you want to understand what’s really holding hydrogen fuel back and why it matters for your energy choices, keep reading. This article will break down the key challenges in hydrogen fuel production in a clear and simple way—so you can see what’s at stake and what needs to change.

High Production Costs

Producing hydrogen fuel involves significant costs that limit its wider use. High production costs make it harder for hydrogen to compete with other energy sources. These costs arise from the materials, energy, and technology needed to create hydrogen fuel. Understanding these cost factors helps explain why hydrogen fuel is not yet mainstream.

Expensive Renewable Sources

Green hydrogen relies on renewable energy like wind and solar power. These energy sources need costly equipment and land. Solar panels and wind turbines require large upfront investments. The availability of sunshine or wind also varies, affecting production consistency. Using renewable sources raises the initial price of producing hydrogen fuel.

Energy-intensive Processes

Hydrogen production methods consume large amounts of energy. Electrolysis, which splits water into hydrogen and oxygen, demands high electricity input. The process is less efficient and wastes energy. This energy need increases the overall cost of hydrogen. Efficient and cheaper technology is still under development to lower these costs.

Cost Comparison With Fossil Fuels

Fossil fuels like oil and natural gas are cheaper to produce and use. Their infrastructure and technology are well established. Hydrogen production costs remain higher due to newer technology and renewable energy use. This price gap slows hydrogen adoption. Reducing costs is essential for hydrogen to compete with fossil fuels.

Storage Difficulties

Storing hydrogen fuel poses significant challenges that affect its practical use. Hydrogen’s unique properties require specialized storage methods. These methods must balance safety, efficiency, and cost. Understanding these storage difficulties is key to advancing hydrogen fuel technology.

Low Energy Density By Volume

Hydrogen has low energy density when stored as a gas. It occupies much space compared to liquid fuels. This means tanks must be very large to store useful amounts. Large storage volumes make transportation and handling difficult. Compact storage remains a major technical challenge.

High-pressure Tanks

Compressing hydrogen gas requires tanks that can hold high pressure. These tanks often operate at 350 to 700 bar. High pressure raises safety concerns due to leak risks. Tanks need to be strong and heavy to withstand pressure. This adds cost and limits vehicle range.

Cryogenic Storage Challenges

Hydrogen can be stored as a liquid at very low temperatures. Cryogenic storage requires cooling hydrogen below -253°C. Maintaining such cold temperatures consumes energy and complex insulation. Boil-off losses occur as some hydrogen vaporizes. This method needs advanced technology and raises safety issues.

Transportation Risks

Transporting hydrogen fuel involves several risks that affect safety and efficiency. This fuel’s unique properties create challenges during movement from production sites to end-users. Understanding these risks helps improve handling and reduces accidents.

Hydrogen Flammability

Hydrogen is extremely flammable and ignites easily. Its ignition energy is much lower than gasoline or natural gas. Even a small spark can cause a fire or explosion. This flammability demands strict safety measures during transport. Special containers and careful handling are essential to prevent accidents.

Leak Detection Issues

Hydrogen is colorless and odorless, making leaks hard to detect. Its molecules are very small and can escape through tiny cracks. Traditional gas detectors often fail to sense hydrogen quickly. Advanced sensors and regular inspections are necessary to find leaks early. Quick leak detection prevents dangerous buildups and potential fires.

Material Compatibility

Hydrogen reacts differently with many materials used in pipes and tanks. It can cause metal to become brittle and crack over time. This problem, called hydrogen embrittlement, weakens storage and transport equipment. Using compatible materials like stainless steel or special alloys increases safety. Regular maintenance checks ensure materials remain reliable during transport.

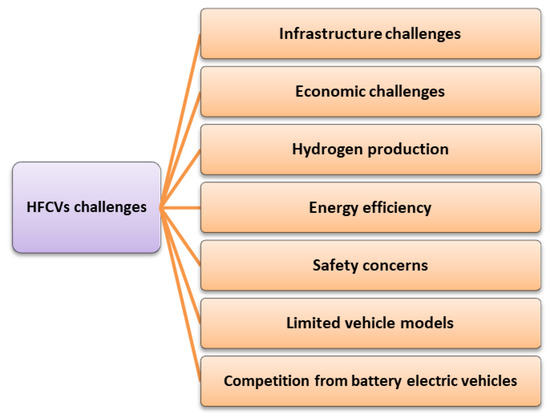

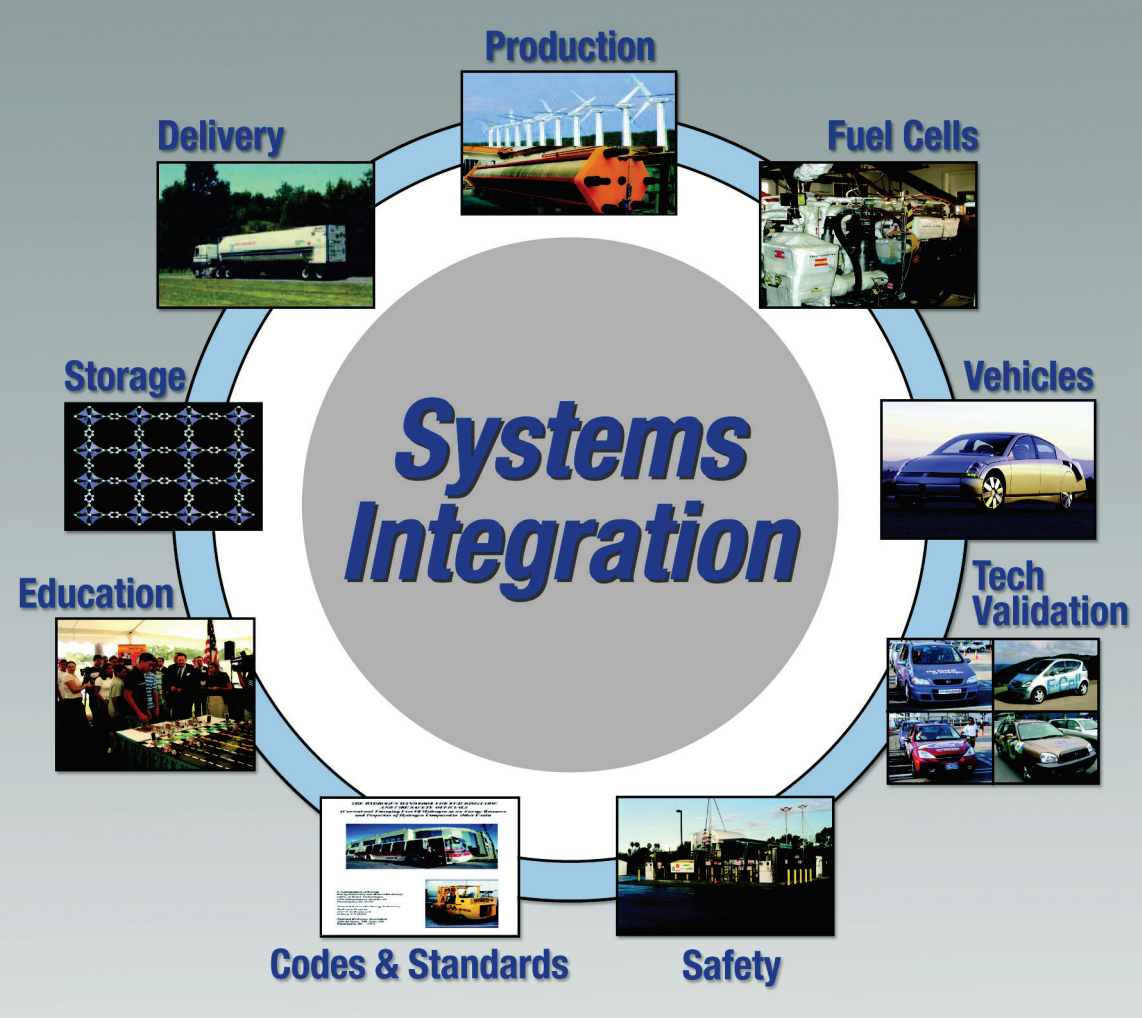

Infrastructure Limitations

Hydrogen fuel has great potential as a clean energy source. Still, many infrastructure limits slow down its growth. Building the right systems for production, storage, and delivery is costly and complex. Without strong infrastructure, hydrogen fuel cannot reach many users efficiently.

Lack Of Refueling Stations

One major issue is the small number of refueling stations. Few stations mean limited access for hydrogen vehicles. Drivers cannot rely on finding fuel easily. This reduces consumer interest in buying hydrogen cars. Expanding the network requires large investments and time.

Supply Chain Bottlenecks

Hydrogen production depends on many materials and parts. Some are rare or costly. Transporting hydrogen safely also needs special equipment. These factors create delays and raise costs. Supply chain problems stop smooth production and delivery. They affect how quickly hydrogen fuel can reach markets.

Distribution Network Gaps

The existing fuel distribution networks are built for gasoline and diesel. Hydrogen needs new pipelines, tanks, and transport methods. Many regions lack these facilities. Without a strong distribution network, hydrogen cannot be delivered widely. Filling these gaps is key for future growth in hydrogen use.

Material Degradation

Material degradation is a key challenge in hydrogen fuel production. It affects the safety, efficiency, and cost of hydrogen technologies. Hydrogen interacts with materials in ways that can weaken them over time. Understanding this problem is vital for improving hydrogen fuel systems.

Hydrogen Embrittlement

Hydrogen embrittlement occurs when hydrogen atoms enter metals. This causes metals to become brittle and crack easily. Pipes and storage tanks are at risk of sudden failure. Preventing embrittlement requires special materials and coatings.

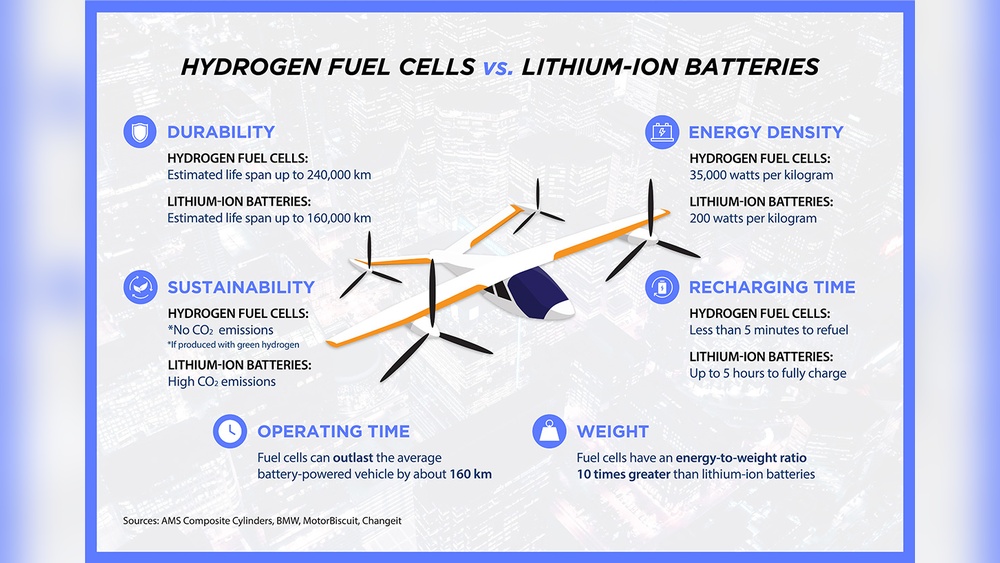

Fuel Cell Durability

Fuel cells convert hydrogen into electricity but face material wear. The repeated chemical reactions stress components inside the cell. This wear reduces cell performance and shortens its life. Research focuses on materials that last longer under harsh conditions.

Component Lifespan

Every part in hydrogen systems has a limited lifespan due to degradation. Valves, seals, and membranes suffer from constant exposure to hydrogen. Replacing parts often raises maintenance costs. Developing durable components helps lower costs and improve reliability.

Efficiency Concerns

Efficiency concerns are central to the challenges in hydrogen fuel production. Producing hydrogen requires significant energy input, and the current methods often lose much of that energy. These losses affect the overall viability and cost of hydrogen as a clean fuel. Understanding where and why energy is lost helps improve production processes and fuel use.

Electrolysis Efficiency

Electrolysis splits water into hydrogen and oxygen using electricity. The process depends heavily on the electricity source and technology used. Typical electrolysis systems convert only 60% to 80% of the electricity into hydrogen energy. This means a large portion of electricity is wasted as heat or other forms of energy. Improving electrolysis efficiency is key to making hydrogen production more sustainable and affordable.

Fuel Cell Performance

Fuel cells convert hydrogen back into electricity to power vehicles or devices. Their performance impacts the overall energy efficiency of hydrogen fuel. Most fuel cells operate between 40% and 60% efficiency. Energy is lost due to internal resistance and heat generation. Enhancing fuel cell design and materials can boost performance and reduce energy waste.

Energy Losses In Production

Besides electrolysis and fuel cells, other steps in hydrogen production cause energy losses. Compressing, storing, and transporting hydrogen consume additional energy. Each step reduces the net energy gain from hydrogen fuel. These losses make the fuel less competitive compared to traditional energy sources. Reducing energy losses throughout the supply chain is essential for a cleaner, more efficient hydrogen economy.

Environmental Impacts

Hydrogen fuel offers a clean energy option but has environmental concerns. Producing and handling hydrogen impacts the environment in several ways. Understanding these effects helps improve production methods and reduce harm.

Hydrogen Leakage Effects

Hydrogen molecules are very small and can escape easily. Leaked hydrogen can increase the level of greenhouse gases. It affects the atmosphere and may worsen climate change. Detecting leaks is hard because hydrogen has no smell or color. Careful monitoring is essential to prevent environmental damage.

Source Of Hydrogen Production

The environmental impact depends on how hydrogen is made. Most hydrogen today comes from natural gas, a fossil fuel. This process releases carbon dioxide, a harmful gas. Producing hydrogen from water using electricity is cleaner but needs renewable energy. Using coal or oil increases pollution and harms the planet more.

Carbon Footprint Variations

Hydrogen’s carbon footprint varies by production method. Green hydrogen uses wind or solar power and creates almost no emissions. Blue hydrogen captures carbon emissions but still relies on fossil fuels. Grey hydrogen produces the most emissions with no capture. Choosing the right method is key to lowering environmental impact.

Scaling And Commercialization

Scaling hydrogen fuel production for commercial use faces multiple challenges. The transition from small-scale projects to large, market-ready operations requires overcoming technical and economic barriers. Establishing efficient production and distribution systems is vital. Without this, hydrogen cannot compete with traditional fuels.

Many industries hesitate to adopt hydrogen fuel due to uncertain supply and demand. Infrastructure for storage and transport remains limited. These factors slow down the overall growth of the hydrogen market. Understanding these hurdles helps stakeholders plan better strategies for expansion.

Market Adoption Barriers

Market adoption of hydrogen fuel faces trust and awareness issues. Consumers and businesses often lack knowledge about hydrogen benefits. Safety concerns also reduce interest in its use. The absence of a robust supply chain limits availability and reliability. Competing technologies like batteries hold stronger market positions. Overcoming these barriers requires education and visible success stories.

Regulatory Challenges

Hydrogen production and use face complex regulatory hurdles. Standards for safety, storage, and transport vary widely by region. Permitting processes can be slow and costly. Lack of clear policies reduces investment confidence. Governments must create consistent rules to support hydrogen scale-up. Harmonized regulations help companies plan long-term projects.

Cost Reduction Strategies

High costs remain a major obstacle in hydrogen fuel production. Electrolysis and other green methods need cheaper, more efficient technologies. Scaling up production reduces unit costs through economies of scale. Using renewable energy sources lowers operational expenses. Partnerships between public and private sectors can fund innovation. Continuous research and development drive cost declines over time.

Frequently Asked Questions

What Is The Biggest Problem With Hydrogen Fuel?

The biggest problem with hydrogen fuel is its high production cost and challenging storage due to low energy density and safety risks.

Why Is It So Hard To Produce Hydrogen?

Producing hydrogen is hard due to high energy needs, costly equipment, inefficient fuel cells, and challenging storage requirements.

What Is The Main Challenge In Producing Hydrogen Fuel?

The main challenge in producing hydrogen fuel is its high production cost, especially for green hydrogen from renewable sources.

Which Of These Challenges Of Producing Hydrogen Fuel Is Not True?

The challenge that is not true is that hydrogen fuel cells are very inefficient compared to batteries. They have comparable efficiency in many cases.

Conclusion

Hydrogen fuel production faces many tough challenges today. Costs remain high, especially for green hydrogen from renewable sources. Safe storage and transport are tricky due to hydrogen’s small, leak-prone molecules. Infrastructure for hydrogen is still limited and needs more development.

Energy losses during production and use reduce overall efficiency. Overcoming these issues requires time, effort, and innovation. The future of hydrogen depends on solving these key problems. Progress will make hydrogen a cleaner, more practical energy option for all.