Imagine powering your vehicle with nothing but hydrogen and air, producing only clean water as a byproduct. Sounds futuristic, right?

But this is exactly what fuel cell stack technology in hydrogen vehicles offers. If you’re curious about how these advanced systems work and why they could revolutionize your driving experience, you’re in the right place. Understanding the fuel cell stack—the heart of hydrogen cars—will open your eyes to a world of efficient, eco-friendly transportation.

Keep reading to discover how this technology transforms simple elements into powerful, emission-free energy that could soon power your daily commute.

Fuel Cell Stack Basics

Fuel cell stack technology forms the heart of hydrogen vehicles. This system transforms hydrogen gas into electricity to power the car. Understanding the basics helps grasp how clean energy drives these vehicles.

The fuel cell stack is made up of many small cells working together. Each cell plays a key role in producing electricity through a chemical process. This process emits only water and heat, making it eco-friendly.

Core Components

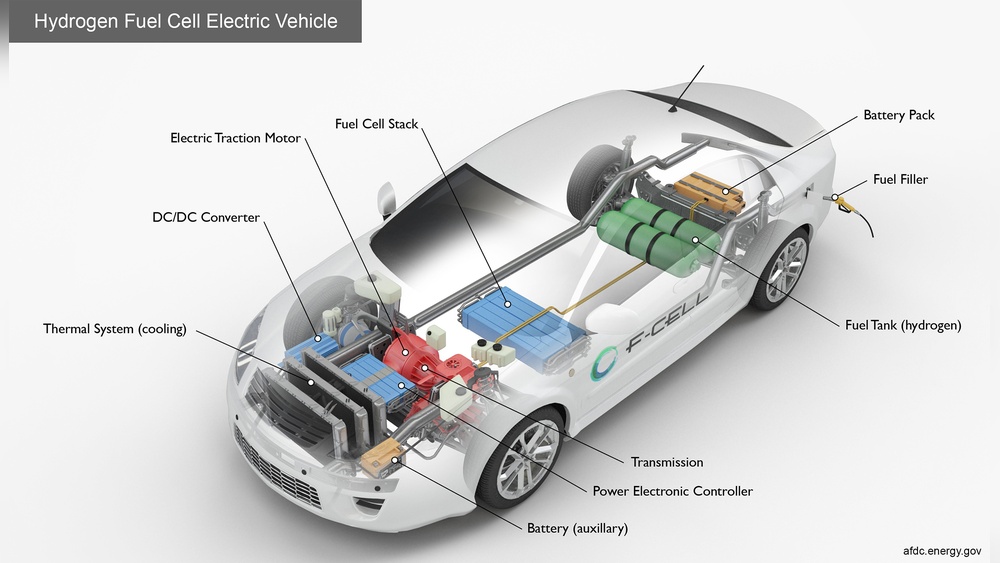

The fuel cell stack includes several essential parts. The main parts are the anode, cathode, and electrolyte membrane. Hydrogen enters through the anode side, while oxygen comes in from the cathode. The membrane allows ions to pass but blocks gases, keeping the reaction controlled.

Electrochemical Reaction

Inside each cell, hydrogen splits into protons and electrons at the anode. Protons move through the membrane to the cathode. Electrons travel through an external circuit, creating electric current to power the motor. At the cathode, oxygen reacts with protons and electrons to form water.

Energy Conversion Process

The fuel cell stack converts chemical energy directly into electrical energy. This process is efficient and clean, producing no harmful emissions. Electricity powers the vehicle’s electric motor and charges the battery. Heat generated can also be used for cabin warming.

Fuel Cell Stack Design

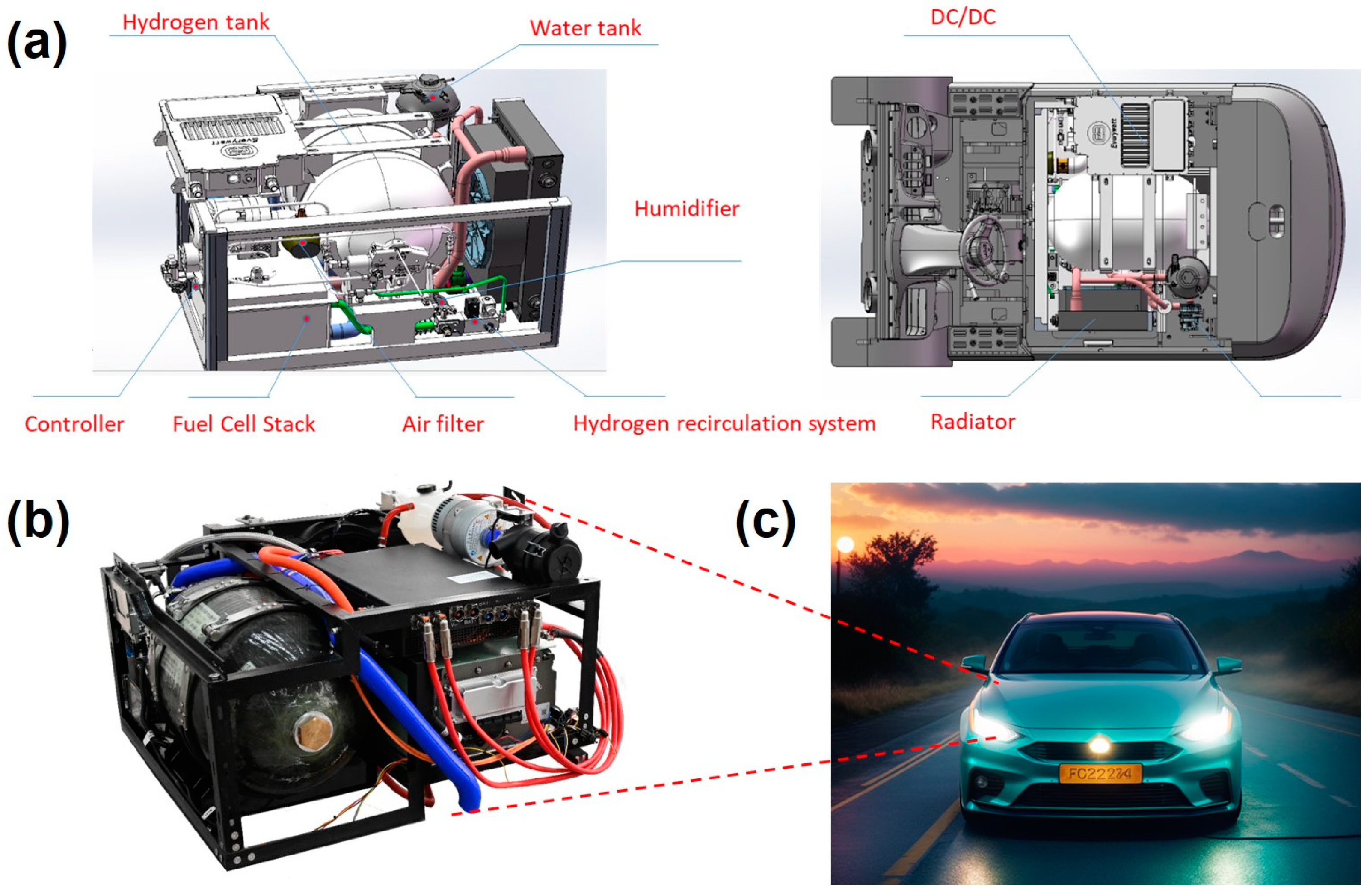

The design of the fuel cell stack is central to hydrogen vehicle performance. It controls how efficiently the stack converts hydrogen into electricity. This design affects power output, size, and durability of the vehicle’s fuel system.

Fuel cell stack design involves careful choice of components and their arrangement. Engineers aim to maximize energy output while keeping the stack compact and reliable. Each layer and material plays a key role.

Membrane Electrode Assembly

The Membrane Electrode Assembly (MEA) forms the heart of the fuel cell stack. It includes a proton exchange membrane sandwiched between two electrodes. The membrane allows protons to pass while blocking electrons. This separation forces electrons to travel through an external circuit, creating electricity.

The electrodes contain catalysts that speed up reactions with hydrogen and oxygen. A well-designed MEA improves efficiency and reduces energy loss. Engineers focus on thin, durable membranes and effective catalysts for better performance.

Stack Configuration

The stack configuration determines how individual cells connect within the fuel cell stack. Cells connect in series to increase voltage and in parallel to increase current. Proper configuration balances power needs and space constraints.

Stack size depends on vehicle power demands. Larger vehicles need more cells to produce enough electricity. Compact stacks fit smaller cars but must maintain high efficiency. The layout also affects cooling and gas flow inside the stack.

Materials And Durability

Materials used in the fuel cell stack must resist heat, moisture, and chemical attack. Durable materials extend stack life and reduce maintenance. Common materials include carbon fiber for plates and platinum for catalysts.

Research aims to find cheaper and longer-lasting materials. Improving durability helps fuel cells withstand many operating cycles. This reliability is crucial for daily driving and long-term vehicle use.

Operation In Hydrogen Vehicles

The operation of fuel cell stack technology in hydrogen vehicles is vital for clean and efficient driving. This technology converts hydrogen fuel into electricity, powering the car’s motor. It works quietly and produces only water as a byproduct. Understanding its operation reveals how hydrogen vehicles maintain performance and safety.

Hydrogen Supply And Management

Hydrogen is stored in high-pressure tanks inside the vehicle. It flows from the tank to the fuel cell stack through controlled valves. Sensors monitor hydrogen levels and pressure constantly. Proper management ensures a steady hydrogen supply. It prevents leaks and maintains system safety.

Electricity Generation

The fuel cell stack combines hydrogen with oxygen from the air. This chemical reaction produces electricity and water vapor. Electricity powers the electric motor and charges the battery. The process is efficient and silent. It provides smooth acceleration without emissions.

Thermal Management

Fuel cells generate heat during electricity production. Thermal management systems remove excess heat to keep the stack cool. Cooling prevents damage and improves fuel cell lifespan. It uses liquid coolants or air to regulate temperature. Maintaining optimal temperature supports continuous vehicle operation.

Advantages Over Conventional Systems

Fuel cell stack technology in hydrogen vehicles offers clear advantages over traditional car engines. These benefits improve both the environment and driving experience. The technology stands out for its clean energy use, efficiency, and convenience. Below are key advantages that make fuel cell stacks a better choice.

Zero Emissions

Fuel cell stacks produce only water vapor as a byproduct. They do not emit harmful gases like carbon dioxide or nitrogen oxides. This feature helps reduce air pollution and fight climate change. Hydrogen vehicles with fuel cells support cleaner cities and healthier air.

High Efficiency

Fuel cell stacks convert hydrogen directly into electricity. This process is more efficient than burning gasoline or diesel. It uses energy better and wastes less fuel. Higher efficiency means longer driving range and lower energy costs. The technology also runs quietly, making rides smoother.

Refueling Speed

Hydrogen vehicles refuel quickly, similar to gasoline cars. Filling a tank takes about 3 to 5 minutes. This is much faster than charging a battery electric vehicle. Fast refueling allows drivers to continue trips without long stops. It adds convenience and fits well into daily life.

Challenges And Limitations

Fuel cell stack technology powers hydrogen vehicles with clean energy. Despite its promise, several challenges limit its widespread use. Understanding these hurdles helps in grasping the technology’s current state and future potential.

Cost And Manufacturing

Fuel cell stacks use expensive materials like platinum. This raises the overall cost of hydrogen vehicles. Manufacturing these stacks requires precision and advanced technology. Mass production remains limited, keeping prices high. Reducing costs is vital for wider adoption.

Hydrogen Storage

Storing hydrogen safely is difficult. Hydrogen is a very light gas and takes up a lot of space. Compressing or liquefying hydrogen requires special tanks. These tanks must withstand high pressure and extreme conditions. Storage challenges affect vehicle range and safety.

Infrastructure Needs

Hydrogen refueling stations are scarce worldwide. Building this infrastructure needs large investment and planning. Without enough stations, hydrogen vehicles cannot travel long distances easily. Expanding the network is essential to support users. Infrastructure development lags behind other fuel types.

Recent Innovations

Recent innovations in fuel cell stack technology have greatly improved hydrogen vehicles. These advances enhance efficiency, durability, and integration, making fuel cells more practical and reliable. Engineers focus on materials, performance, and system compatibility to push hydrogen cars forward.

Advanced Materials

New materials help fuel cells work better and last longer. Researchers develop membranes that conduct ions efficiently. Catalysts now use less precious metal, reducing costs. These materials resist degradation under heat and pressure. This leads to stronger, more durable fuel cell stacks.

Stack Performance Improvements

Fuel cell stacks now deliver higher power output and faster response times. Improved water management prevents flooding and drying inside the stack. Innovations reduce energy losses and improve overall efficiency. Better thermal management keeps the stack at optimal temperatures. These changes boost vehicle range and reliability.

Integration With Vehicle Systems

Fuel cell stacks now fit seamlessly into vehicle designs. Control systems optimize stack operation based on driving conditions. Integration with batteries balances power supply and demand. Cooling and ventilation systems are tailored for fuel cell needs. This synergy enhances performance and passenger comfort.

Leading Manufacturers

Several top companies lead the development of fuel cell stack technology for hydrogen vehicles. They invest in research and improve stack performance. Their innovations make hydrogen cars more efficient and reliable. These manufacturers focus on durability, power output, and cost reduction. Their work pushes the hydrogen vehicle industry forward.

Toyota’s Fuel Cell Technology

Toyota is a pioneer in fuel cell stack technology. Their stacks deliver high power and long life. Toyota’s design uses advanced materials for better efficiency. The Mirai model showcases this technology on the road. Toyota continues to refine stack size and weight. This helps increase driving range and reduce costs.

Honda’s Stack Systems

Honda develops compact and efficient fuel cell stacks. Their systems balance power and size for vehicle integration. Honda’s stacks focus on quick startup and durability. The Clarity Fuel Cell uses this technology. Honda aims to make fuel cells more affordable. Their research includes improving water management inside the stack.

Nuvera’s Demonstrations

Nuvera offers fuel cell stacks for commercial and passenger vehicles. They demonstrate stacks with high power density and reliability. Nuvera’s technology supports heavy-duty applications and fleets. Their stacks are modular for easy maintenance and scaling. Nuvera works closely with vehicle makers for integration. Their demos prove stacks perform well in real conditions.

Future Trends

Fuel cell stack technology in hydrogen vehicles is evolving rapidly. New trends focus on making these systems more practical and efficient. The future holds promising developments that could expand hydrogen use in transportation and energy.

Scalability

Fuel cell stacks are becoming easier to scale for different vehicle sizes. Manufacturers design stacks that fit small cars to large trucks. This flexibility helps hydrogen vehicles reach more market segments. Modular designs allow quick assembly and repair. Scaling up production also supports mass adoption of hydrogen vehicles.

Cost Reduction Strategies

Reducing costs remains a key focus in fuel cell stack development. Using cheaper materials without losing performance is a major goal. Advances in manufacturing processes cut production time and waste. Recycling components from old stacks lowers raw material needs. These strategies make hydrogen vehicles more affordable for buyers.

Broader Clean Energy Impact

Fuel cell stacks will play a larger role beyond vehicles. They can provide clean power for homes and businesses. Integrating stacks with renewable energy sources improves energy storage. Hydrogen generated from excess solar or wind can be stored and used later. This supports a cleaner, more reliable energy grid worldwide.

Frequently Asked Questions

What Is A Fuel Cell Stack In Hydrogen Vehicles?

A fuel cell stack is a collection of individual fuel cells stacked together. It converts hydrogen and oxygen into electricity through an electrochemical reaction. This electricity powers the vehicle’s motor, enabling clean and efficient transportation with water as the only emission.

How Does Fuel Cell Stack Technology Work?

Fuel cell stacks generate electricity by combining hydrogen from the tank with oxygen from the air. This reaction produces electrical energy, water, and heat. The electricity then powers the electric motor, allowing the vehicle to run smoothly without harmful emissions.

Why Is Fuel Cell Stack Important For Hydrogen Cars?

The fuel cell stack is the core component that produces electricity in hydrogen vehicles. It enables efficient energy conversion, longer driving ranges, and quick refueling. This technology supports zero-emission transportation, reducing environmental impact compared to traditional combustion engines.

What Are The Advantages Of Fuel Cell Stack Technology?

Fuel cell stacks offer high efficiency, fast refueling, and zero tailpipe emissions. They provide longer driving ranges than batteries and produce only water as a byproduct. This makes hydrogen vehicles environmentally friendly and practical for daily use.

Conclusion

Fuel cell stack technology powers hydrogen vehicles efficiently and cleanly. It turns hydrogen and oxygen into electricity without harmful emissions. This technology supports longer driving ranges and faster refueling. Hydrogen vehicles offer a promising alternative to traditional fuel cars. As fuel cell stacks improve, expect better performance and lower costs.

The future of clean transportation depends on innovations like these. Understanding this technology helps us appreciate its role in reducing pollution. Cleaner air and quieter roads could become the new normal. Hydrogen fuel cell vehicles hold great potential for sustainable travel.