Hydrogen fuel cells are revolutionizing the commercial vehicle industry by offering a clean, efficient alternative to diesel engines. From long-haul trucks to city buses, these zero-emission powertrains are helping fleets reduce carbon footprints while maintaining performance and range.

Key Takeaways

- Zero Emissions Operation: Hydrogen fuel cells produce only water vapor as a byproduct, making them ideal for reducing greenhouse gas emissions in transportation.

- Long Range and Fast Refueling: Unlike battery-electric vehicles, hydrogen-powered commercial vehicles can travel 300–500 miles and refuel in under 15 minutes.

- Ideal for Heavy-Duty Applications: Fuel cells provide high energy density, making them well-suited for trucks, buses, and delivery vans that require sustained power and durability.

- Growing Infrastructure Support: Governments and private companies are investing in hydrogen refueling networks, especially in Europe, North America, and Asia.

- Lower Operational Costs Over Time: Despite higher upfront costs, hydrogen fleets can reduce maintenance and fuel expenses in the long run due to fewer moving parts and stable fuel pricing.

- Complementary to Battery Electric: Hydrogen fuel cells are not replacing EVs but filling a critical gap for applications where batteries are less practical.

- Real-World Deployments Increasing: Companies like Toyota, Hyundai, and Nikola are already testing and deploying hydrogen-powered commercial vehicles globally.

📑 Table of Contents

- Introduction: The Shift Toward Clean Commercial Transportation

- How Hydrogen Fuel Cells Work in Commercial Vehicles

- Types of Commercial Vehicles Using Hydrogen Fuel Cells

- Real-World Examples and Success Stories

- Challenges and Barriers to Adoption

- The Future of Hydrogen in Commercial Transportation

- Conclusion: A Cleaner Road Ahead

Introduction: The Shift Toward Clean Commercial Transportation

The commercial vehicle sector is under increasing pressure to reduce its environmental impact. Trucks, buses, delivery vans, and other heavy-duty vehicles are responsible for a significant portion of global carbon emissions—especially in urban areas where air quality is a major concern. While battery-electric vehicles (BEVs) have made impressive strides in passenger cars and light-duty fleets, they still face limitations when it comes to heavy-duty, long-range applications. That’s where hydrogen fuel cells come in.

Hydrogen fuel cells offer a promising solution. They generate electricity through a chemical reaction between hydrogen and oxygen, producing only water and heat as byproducts. This makes them a truly zero-emission power source when the hydrogen is produced using renewable energy. Unlike batteries, which can take hours to recharge and add substantial weight, hydrogen fuel cells provide quick refueling and high energy density—ideal for commercial operations that can’t afford downtime.

As governments tighten emissions regulations and companies commit to sustainability goals, hydrogen-powered commercial vehicles are moving from concept to reality. From logistics giants like Amazon and UPS to public transit agencies in cities like London and Tokyo, fleets are beginning to adopt this technology. The shift isn’t just about going green—it’s about building a more efficient, resilient, and future-ready transportation system.

How Hydrogen Fuel Cells Work in Commercial Vehicles

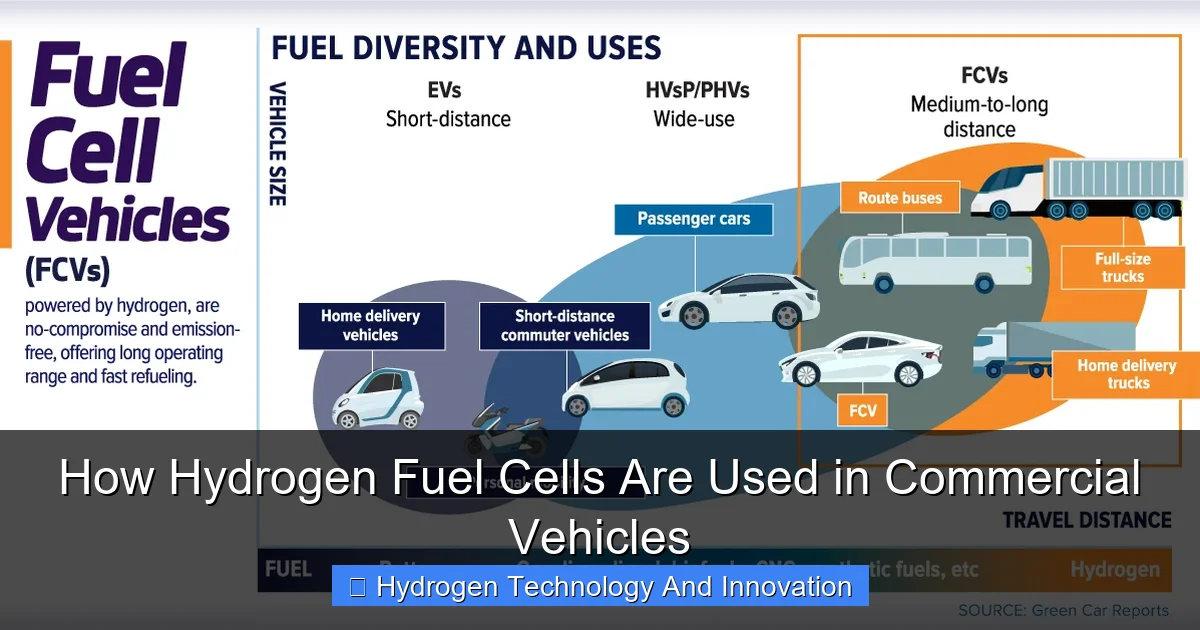

Visual guide about How Hydrogen Fuel Cells Are Used in Commercial Vehicles

Image source: visualcapitalist.com

At the heart of every hydrogen-powered commercial vehicle is the fuel cell stack—a series of individual fuel cells that work together to generate electricity. Each cell contains an anode, a cathode, and an electrolyte membrane. When hydrogen gas is fed into the anode, it splits into protons and electrons. The protons pass through the membrane to the cathode, while the electrons are forced through an external circuit, creating an electric current that powers the vehicle’s motor.

The only byproduct of this reaction is water vapor, which exits through the exhaust—making hydrogen fuel cells one of the cleanest energy sources available. The electricity generated can either power the vehicle directly or charge a small onboard battery that assists during acceleration or stores energy from regenerative braking.

Key Components of a Hydrogen Fuel Cell System

A typical hydrogen fuel cell system in a commercial vehicle includes several critical components:

– Fuel Cell Stack: The core unit where the electrochemical reaction occurs. Modern stacks are designed for durability and efficiency, often lasting over 20,000 hours of operation.

– Hydrogen Storage Tanks: High-pressure tanks (usually 350 or 700 bar) store compressed hydrogen gas. These tanks are made from lightweight composite materials to ensure safety and minimize weight.

– Electric Motor: Converts the electricity from the fuel cell into mechanical power to drive the wheels.

– Power Control Unit: Manages the flow of electricity between the fuel cell, battery, and motor, ensuring optimal performance and efficiency.

– Thermal Management System: Keeps the fuel cell stack at the ideal operating temperature, which is crucial for efficiency and longevity.

Advantages Over Traditional and Battery-Electric Systems

Hydrogen fuel cells offer several advantages that make them particularly well-suited for commercial vehicles:

– Fast Refueling: Refilling a hydrogen tank takes 10–15 minutes—comparable to diesel and much faster than charging a large battery.

– Long Range: Most hydrogen-powered trucks and buses can travel 300–500 miles on a single tank, making them viable for long-haul routes.

– Lightweight: Unlike heavy battery packs, hydrogen systems add less weight to the vehicle, preserving payload capacity.

– Consistent Performance: Fuel cells maintain steady power output regardless of temperature, unlike batteries, which can lose efficiency in cold weather.

These benefits are especially valuable for fleet operators who need reliability, uptime, and operational flexibility.

Types of Commercial Vehicles Using Hydrogen Fuel Cells

Hydrogen fuel cells are being integrated into a wide range of commercial vehicles, each benefiting from the technology’s unique strengths. While passenger cars get more media attention, the real momentum is in the commercial sector—where emissions reductions have the biggest impact.

Heavy-Duty Trucks

Long-haul freight trucks are among the most promising applications for hydrogen fuel cells. These vehicles travel thousands of miles per week and require high energy density and quick refueling. Companies like Nikola Motor Company and Hyundai have developed hydrogen-powered semi-trucks designed for cross-country routes.

For example, Hyundai’s XCIENT Fuel Cell truck has been deployed in Switzerland, where a fleet of over 40 vehicles has logged more than 5 million kilometers. These trucks can carry up to 34 tons and refuel in under 10 minutes, offering a practical alternative to diesel without sacrificing performance.

City and Intercity Buses

Public transit agencies are increasingly turning to hydrogen buses to reduce urban pollution. Cities like London, Tokyo, and Aberdeen have introduced hydrogen-powered buses that operate on fixed routes with centralized refueling stations.

The Wrightbus StreetDeck Hydroliner, used in the UK, can carry up to 87 passengers and travel over 300 miles on a single tank. These buses are quiet, emit no pollutants, and help cities meet air quality targets. Plus, their predictable routes make it easier to build refueling infrastructure.

Delivery and Logistics Vehicles

Last-mile delivery is another area where hydrogen is gaining traction. Companies like Amazon and UPS are testing hydrogen-powered vans and medium-duty trucks for urban distribution.

These vehicles benefit from the quick refueling and extended range, allowing drivers to complete full-day routes without returning to base for charging. Hydrogen also eliminates the need for large battery packs, freeing up cargo space.

Refuse and Utility Trucks

Garbage trucks and utility vehicles often operate on fixed routes with frequent stops and starts. Hydrogen fuel cells provide the consistent power needed for hydraulic systems and onboard equipment, while also reducing noise and emissions in residential areas.

In the U.S., cities like Fountain Valley, California, have deployed hydrogen-powered refuse trucks that run on waste-derived hydrogen, creating a closed-loop sustainability model.

Specialized and Off-Road Vehicles

Beyond road vehicles, hydrogen fuel cells are being used in airport ground support equipment, mining trucks, and port cargo handlers. These applications benefit from the high torque and reliability of fuel cells, especially in environments where battery charging is impractical.

Real-World Examples and Success Stories

The adoption of hydrogen fuel cells in commercial vehicles is no longer theoretical. Around the world, companies and governments are launching pilot programs and full-scale deployments that demonstrate the technology’s viability.

Hyundai’s Global XCIENT Fleet

Hyundai has been a pioneer in hydrogen trucking. In 2020, it launched the world’s first mass-produced hydrogen-powered heavy-duty truck, the XCIENT Fuel Cell. The initial fleet of 46 trucks was deployed in Switzerland, where they are used for grocery delivery, logistics, and waste management.

The program has been a success. The trucks have proven reliable, with an average uptime of over 90%. Refueling infrastructure is supported by a partnership with Hydrospider, a joint venture that produces green hydrogen from renewable energy. Hyundai has since expanded the program to Germany, South Korea, and the U.S., with plans for over 1,600 trucks by 2025.

Toyota and Kenworth’s Project Portal

In California, Toyota and Kenworth collaborated on Project Portal, a hydrogen-powered Class 8 truck designed for port drayage. The truck uses two Toyota fuel cell stacks and can haul up to 80,000 pounds.

The project demonstrated that hydrogen trucks can handle the demanding conditions of port operations, including steep grades and long idle times. The success led to the development of the Kenworth T680 Fuel Cell Electric Vehicle, now being tested in real-world logistics operations.

London’s Hydrogen Bus Initiative

Transport for London (TfL) has introduced a fleet of hydrogen double-decker buses as part of its effort to achieve zero-emission public transit. The buses, built by Wrightbus, run on routes across the city and are refueled at a dedicated station in East London.

Passengers have praised the quiet, smooth ride, and the buses have helped reduce NOx and particulate emissions in high-traffic areas. TfL plans to expand the fleet and integrate more hydrogen vehicles into its network.

Amazon’s Hydrogen Delivery Vans

Amazon has partnered with Plug Power to develop hydrogen-powered delivery vans for its last-mile logistics. The vans use Plug’s GenDrive fuel cells and are being tested in California and New York.

The goal is to create a zero-emission delivery fleet that can operate efficiently in urban environments. Amazon’s investment in hydrogen infrastructure, including on-site refueling stations, shows its long-term commitment to the technology.

Challenges and Barriers to Adoption

Despite the promise of hydrogen fuel cells, several challenges remain before they can achieve widespread adoption in the commercial vehicle sector.

High Upfront Costs

Hydrogen fuel cell vehicles are currently more expensive than diesel or battery-electric alternatives. The fuel cell stack, hydrogen storage tanks, and specialized components drive up manufacturing costs. However, prices are expected to fall as production scales up and technology improves.

Government incentives and subsidies can help bridge the gap. For example, the U.S. Inflation Reduction Act includes tax credits for clean vehicle purchases, including hydrogen-powered trucks.

Limited Refueling Infrastructure

One of the biggest hurdles is the lack of hydrogen refueling stations. Unlike electric charging networks, which are expanding rapidly, hydrogen infrastructure is still in its infancy.

Most existing stations are clustered in regions like California, Germany, and Japan. Building a nationwide network requires significant investment and coordination between governments, energy companies, and vehicle manufacturers.

Hydrogen Production and Sustainability

Not all hydrogen is created equal. Most hydrogen today is produced from natural gas through a process called steam methane reforming, which emits carbon dioxide. This “gray hydrogen” undermines the environmental benefits of fuel cells.

To be truly sustainable, hydrogen must be produced using renewable energy—through electrolysis of water. This “green hydrogen” is cleaner but more expensive. Scaling up green hydrogen production is essential for the long-term success of fuel cell vehicles.

Storage and Transportation Challenges

Hydrogen is the lightest element and has low energy density by volume, making it difficult to store and transport. It must be compressed or liquefied, which requires energy and specialized equipment.

Leakage is also a concern, as hydrogen can embrittle metals and escape through tiny gaps. Advances in materials science and tank design are helping to address these issues, but they remain areas of active research.

Public Perception and Safety Concerns

Some people associate hydrogen with the Hindenburg disaster, leading to safety concerns. However, modern hydrogen systems are designed with multiple safety features, including leak detection, pressure relief valves, and robust tank construction.

In fact, hydrogen is no more dangerous than gasoline or natural gas when handled properly. Education and transparency are key to building public trust.

The Future of Hydrogen in Commercial Transportation

The future looks bright for hydrogen fuel cells in commercial vehicles. As technology improves and costs decline, adoption is expected to accelerate. Several trends are shaping this future:

Scaling Up Production

Automakers and fuel cell manufacturers are investing heavily in scaling production. Hyundai plans to produce 100,000 fuel cell systems annually by 2030. Toyota is expanding its fuel cell production in Kentucky. These efforts will drive down costs and increase availability.

Government Support and Policy

Governments around the world are introducing policies to support hydrogen adoption. The European Union’s Hydrogen Strategy aims to install 1,000 hydrogen refueling stations by 2030. The U.S. Department of Energy’s H2@Scale initiative promotes hydrogen as a key part of the clean energy transition.

Incentives, grants, and low-interest loans are helping fleets transition to hydrogen vehicles. California’s Hybrid and Zero-Emission Truck and Bus Voucher Incentive Project (HVIP) has already supported hundreds of hydrogen vehicle purchases.

Integration with Renewable Energy

The growth of wind, solar, and hydropower is making green hydrogen more viable. Excess renewable energy can be used to produce hydrogen during off-peak hours, storing it for later use. This creates a flexible, clean energy system that supports both transportation and grid stability.

Collaboration Across Industries

Success will depend on collaboration. Automakers, energy companies, logistics firms, and governments must work together to build the ecosystem. Partnerships like the Hydrogen Council—a global CEO-led initiative—are driving innovation and investment.

Emerging Technologies

Research is ongoing to improve fuel cell efficiency, durability, and cost. Solid oxide fuel cells, anion exchange membranes, and new catalysts are being explored. These advancements could make hydrogen vehicles even more competitive.

Conclusion: A Cleaner Road Ahead

Hydrogen fuel cells are not a silver bullet, but they are a critical piece of the puzzle in decarbonizing commercial transportation. They offer a practical, zero-emission solution for heavy-duty vehicles that can’t rely on batteries alone. With fast refueling, long range, and high performance, hydrogen-powered trucks, buses, and vans are already proving their value in real-world applications.

While challenges remain—especially around cost and infrastructure—the momentum is undeniable. As technology advances and the hydrogen economy grows, we can expect to see more fleets making the switch. The road ahead is cleaner, quieter, and more sustainable, thanks to hydrogen fuel cells.

For fleet managers, logistics companies, and policymakers, now is the time to explore hydrogen options. Whether it’s a single delivery van or a full fleet of long-haul trucks, the benefits are clear: reduced emissions, lower operating costs, and a future-ready transportation system.

The shift is happening. And hydrogen is leading the charge.

Frequently Asked Questions

What are hydrogen fuel cells and how do they work?

Hydrogen fuel cells generate electricity through a chemical reaction between hydrogen and oxygen, producing only water and heat as byproducts. They power electric motors in vehicles, offering a clean alternative to fossil fuels.

Are hydrogen fuel cell vehicles really zero emission?

Yes, when powered by green hydrogen produced from renewable energy, fuel cell vehicles emit only water vapor. However, if the hydrogen is made from natural gas, emissions are still involved in production.

How long does it take to refuel a hydrogen commercial vehicle?

Refueling typically takes 10–15 minutes, similar to diesel trucks. This is much faster than charging large battery-electric vehicles, which can take several hours.

What is the range of a hydrogen-powered truck or bus?

Most hydrogen commercial vehicles can travel between 300 and 500 miles on a single tank, making them suitable for long-haul and regional routes.

Is hydrogen safe for use in vehicles?

Yes, modern hydrogen systems include multiple safety features like leak detection and pressure relief valves. When handled properly, hydrogen is as safe as other fuels.

Where can hydrogen commercial vehicles be refueled?

Refueling stations are currently limited but growing, especially in California, Europe, and parts of Asia. Many fleets use centralized depots with on-site hydrogen production or delivery.