Hydrogen car manufacturing blends advanced engineering, clean energy tech, and precision assembly. From fuel cell stacks to hydrogen tanks, every component is designed for safety, efficiency, and zero emissions.

Key Takeaways

- Hydrogen cars use fuel cells, not combustion engines: They generate electricity through a chemical reaction between hydrogen and oxygen, producing only water as a byproduct.

- Fuel cell stacks are the heart of the system: Multiple individual fuel cells are layered to create enough power to run the vehicle.

- High-pressure hydrogen storage is critical: Tanks must safely hold compressed hydrogen at up to 700 bar, requiring advanced materials and rigorous testing.

- Manufacturing involves multiple specialized stages: From membrane electrode assembly to final vehicle integration, each step demands precision and quality control.

- Safety is a top priority: Leak detection, crash resistance, and fail-safe systems are built into every hydrogen vehicle.

- Automation and robotics improve consistency: Modern factories use AI and robotics to assemble delicate components with high accuracy.

- Hydrogen cars support a sustainable future: When powered by green hydrogen, they offer a truly zero-emission transportation solution.

📑 Table of Contents

Introduction to Hydrogen Car Technology

Imagine driving a car that emits nothing but clean water vapor from its tailpipe. No smog, no carbon dioxide, no harmful pollutants—just silent, smooth, and sustainable mobility. That’s the promise of hydrogen-powered vehicles. Unlike electric cars that rely on large lithium-ion batteries, hydrogen cars generate their own electricity on board using a fuel cell. This technology is reshaping the future of clean transportation, especially for long-haul trucks, buses, and even passenger vehicles in regions with limited charging infrastructure.

Hydrogen cars, also known as fuel cell electric vehicles (FCEVs), are not science fiction. Companies like Toyota, Hyundai, and Honda have already launched production models such as the Toyota Mirai and Hyundai NEXO. These vehicles are refueled in minutes—just like gasoline cars—and offer ranges exceeding 300 miles on a single tank. But how are these futuristic machines actually built? The hydrogen car manufacturing process is a fascinating blend of chemistry, engineering, and high-tech assembly. It’s not just about slapping a fuel cell under the hood; it’s a carefully orchestrated process that ensures safety, performance, and reliability.

In this article, we’ll walk you through every major stage of hydrogen car manufacturing—from the creation of the fuel cell stack to the final integration of the vehicle. Whether you’re a tech enthusiast, a student, or someone curious about green transportation, this guide will give you a clear, easy-to-understand look at how hydrogen cars are made. You’ll learn about the materials used, the machines involved, and the safety measures that make these vehicles not just innovative, but also safe for everyday use.

Understanding the Core Components of a Hydrogen Car

Visual guide about Hydrogen Car Manufacturing Process Explained

Image source: khatabook-assets.s3.amazonaws.com

Before diving into the manufacturing process, it’s important to understand what makes a hydrogen car tick. At its core, a hydrogen car has three main systems: the fuel cell stack, the hydrogen storage system, and the electric drivetrain. Each plays a crucial role in converting hydrogen into motion.

The Fuel Cell Stack: The Power Generator

The fuel cell stack is the engine of a hydrogen car—but instead of burning fuel, it uses a clean chemical reaction. Inside each fuel cell, hydrogen gas (H₂) from the tank flows into the anode side, while oxygen (from the air) enters the cathode side. A special membrane, called the proton exchange membrane (PEM), sits between them. This membrane allows only positively charged hydrogen ions (protons) to pass through to the cathode. The electrons, however, are forced to travel through an external circuit, creating an electric current that powers the car’s motor.

This process produces only water and heat as byproducts—no greenhouse gases, no soot, nothing but pure H₂O. A single fuel cell generates about 0.6 to 0.8 volts, which isn’t enough to power a car. That’s why manufacturers stack hundreds of these cells together in a precise sequence. This layered structure is called a fuel cell stack. The more cells in the stack, the more power the vehicle can produce. For example, the Toyota Mirai uses a stack with over 300 individual cells to generate around 114 kilowatts of power—enough to accelerate smoothly and maintain highway speeds.

Hydrogen Storage Tanks: Safe and High-Pressure

Storing hydrogen safely is one of the biggest challenges in hydrogen car design. Hydrogen is the lightest and smallest molecule, which makes it prone to leaking and requires high pressure to store enough for a decent driving range. Most hydrogen cars use Type IV composite tanks—lightweight cylinders made of carbon fiber wrapped around a polymer liner. These tanks can withstand pressures up to 700 bar (over 10,000 psi), which is about 30 times the pressure of a typical car tire.

The tanks are typically mounted in the floor of the vehicle, between the axles, to lower the center of gravity and improve stability. They’re designed to survive extreme conditions, including crashes, fires, and punctures. During manufacturing, each tank undergoes rigorous testing, including burst tests, drop tests, and exposure to extreme temperatures. Sensors inside the tank monitor pressure and temperature in real time, and automatic shut-off valves prevent leaks in case of an accident.

The Electric Drivetrain: Quiet and Efficient

Once the fuel cell generates electricity, it powers an electric motor—just like in a battery-electric vehicle. The motor drives the wheels, providing instant torque and a smooth, quiet ride. Many hydrogen cars also include a small lithium-ion battery to store excess energy and assist during acceleration. This hybrid approach improves efficiency and extends the life of the fuel cell.

The electric drivetrain includes inverters, controllers, and regenerative braking systems. Regenerative braking captures energy during deceleration and feeds it back into the battery, just like in a Tesla or Nissan Leaf. This not only improves range but also reduces wear on the brake pads.

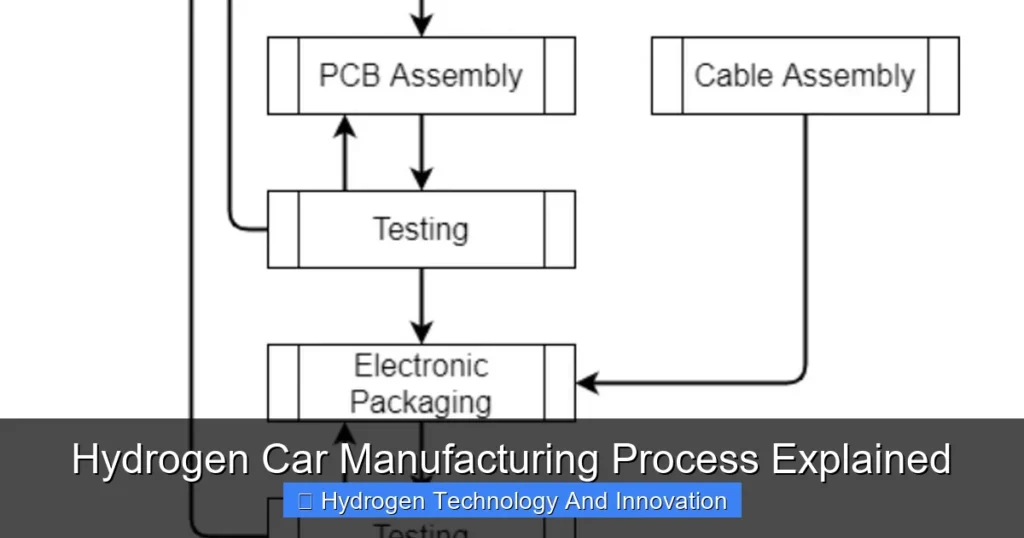

The Hydrogen Car Manufacturing Process: Step by Step

Now that we understand the key components, let’s explore how hydrogen cars are actually built. The manufacturing process is highly specialized and involves several stages, from component fabrication to final assembly. While each automaker may have slight variations, the core steps remain consistent across the industry.

Step 1: Membrane Electrode Assembly (MEA) Production

The journey begins with the creation of the membrane electrode assembly (MEA), the heart of each fuel cell. The MEA consists of the proton exchange membrane, coated on both sides with a catalyst—usually platinum nanoparticles—and sandwiched between gas diffusion layers (GDLs). This delicate sandwich is where the magic happens: hydrogen splits into protons and electrons, and electricity is generated.

Manufacturing MEAs requires extreme precision. The membrane must be perfectly uniform, and the catalyst layers must be applied with nanometer-level accuracy. Any contamination or inconsistency can reduce efficiency or cause failure. To achieve this, manufacturers use cleanroom environments similar to those in semiconductor production. Robots apply the catalyst using inkjet printing or spray-coating techniques, ensuring even distribution.

Once the MEA is complete, it’s tested for performance and durability. Some manufacturers use accelerated stress tests, simulating thousands of hours of operation in just a few days. Only MEAs that pass strict quality checks move on to the next stage.

Step 2: Building the Fuel Cell Stack

With the MEAs ready, the next step is assembling the fuel cell stack. This involves layering hundreds of individual cells, each consisting of an MEA, bipolar plates, and sealing gaskets. Bipolar plates—usually made of graphite or coated metal—distribute hydrogen and oxygen to the MEA and collect the electrical current.

The stacking process is highly automated. Robots carefully place each component in sequence, applying precise pressure to ensure a tight seal. The entire stack is then compressed and bolted together to maintain contact between layers. Even a tiny gap can cause performance loss or overheating.

After assembly, the stack undergoes a series of tests. It’s connected to hydrogen and air supplies, and its voltage, current, and efficiency are measured under various loads. Thermal imaging cameras monitor for hot spots, and gas sensors check for leaks. Only stacks that meet performance and safety standards are approved for installation.

Step 3: Hydrogen Tank Fabrication and Testing

While the fuel cell stack is being built, hydrogen storage tanks are manufactured separately. Type IV tanks are made by winding carbon fiber around a polymer liner in a precise pattern. The winding angle and tension are carefully controlled to maximize strength and minimize weight.

Once the tank is formed, it’s cured in an oven to harden the resin. Then comes the most critical phase: testing. Each tank is filled with water and pressurized to 1.5 times its operating pressure (over 1,000 bar) to check for leaks or weaknesses. If it passes, it undergoes additional tests, including:

– Drop tests: The tank is dropped from a height to simulate a crash.

– Fire tests: It’s exposed to flames to ensure it won’t explode.

– Penetration tests: A metal rod is driven into the tank to see if it ruptures.

Only tanks that survive all tests are certified for use in vehicles. These rigorous standards ensure that hydrogen storage is as safe—or safer—than gasoline tanks.

Step 4: Integration into the Vehicle Chassis

With the fuel cell stack and hydrogen tanks ready, the next step is integrating them into the vehicle. This is where traditional automotive assembly meets advanced hydrogen technology. The process begins with the vehicle chassis—often a modified version of an existing electric or hybrid platform.

The fuel cell stack is typically mounted in the front or center of the vehicle, where it’s protected from impacts and has good airflow for cooling. The hydrogen tanks are installed in the floor, secured with reinforced brackets. High-pressure lines made of stainless steel or specialized polymers connect the tanks to the fuel cell.

Next, the electric drivetrain components—motor, inverter, battery, and control units—are installed. These are similar to those in battery-electric vehicles, but the control software is customized for hydrogen operation. For example, the system must manage the flow of hydrogen, monitor stack temperature, and balance power between the fuel cell and battery.

Step 5: Final Assembly and Quality Control

The final assembly stage brings everything together. Wiring harnesses are connected, sensors are calibrated, and software is uploaded. The vehicle is then filled with hydrogen (in a controlled environment) and undergoes a comprehensive systems check.

Technicians use diagnostic tools to verify that all components are communicating properly. They test the fuel cell under load, check for leaks using hydrogen sniffers, and ensure the cooling system is functioning. The vehicle is also driven on a test track to evaluate performance, handling, and noise levels.

Before leaving the factory, each hydrogen car undergoes a final inspection. This includes a visual check, a software update, and a certification stamp. Only then is it approved for delivery to dealerships or customers.

Advanced Technologies in Hydrogen Car Manufacturing

Hydrogen car manufacturing isn’t just about assembling parts—it’s about innovation. Automakers are constantly improving the process with cutting-edge technologies that enhance efficiency, safety, and sustainability.

Automation and Robotics

One of the biggest advancements is the use of automation. Robots handle delicate tasks like MEA coating, stack assembly, and tank winding with unmatched precision. This reduces human error and increases production speed. For example, Hyundai’s fuel cell plant in Chungju, South Korea, uses fully automated lines to produce thousands of stacks per year.

AI-powered vision systems inspect components in real time, detecting microscopic defects that humans might miss. Machine learning algorithms analyze production data to predict failures and optimize processes. This not only improves quality but also reduces waste and downtime.

Green Hydrogen and Sustainable Materials

Sustainability is a core principle in hydrogen car manufacturing. Many companies are shifting to green hydrogen—produced using renewable energy like wind or solar—to power their factories. This ensures that the entire lifecycle of the vehicle is low-carbon.

Manufacturers are also exploring eco-friendly materials. For instance, some are replacing platinum in fuel cells with cheaper, more abundant catalysts like iron-nitrogen-carbon compounds. Others are using recycled carbon fiber for tanks and biodegradable polymers for seals.

Digital Twins and Simulation

Before a single car is built, engineers use digital twins—virtual models of the vehicle and its components. These simulations test everything from aerodynamics to crash safety, allowing designers to refine the product without physical prototypes. This speeds up development and reduces costs.

During manufacturing, digital twins monitor the production line in real time. Sensors collect data on temperature, pressure, and vibration, which is fed into the model to predict maintenance needs and prevent breakdowns.

Safety and Environmental Considerations

Safety is paramount in hydrogen car manufacturing. Hydrogen is highly flammable and invisible when burning, which requires special precautions. Factories are equipped with hydrogen detectors, ventilation systems, and explosion-proof equipment. Workers wear protective gear and undergo extensive training.

Environmental impact is also a key concern. While hydrogen cars produce zero emissions on the road, the production process can be energy-intensive. That’s why manufacturers are investing in renewable energy, recycling programs, and carbon offset initiatives. The goal is to make hydrogen cars not just clean to drive, but clean to build.

Conclusion

The hydrogen car manufacturing process is a marvel of modern engineering. From the nanoscale precision of fuel cell production to the high-pressure safety of hydrogen storage, every step is designed to deliver a vehicle that’s efficient, reliable, and environmentally friendly. As technology advances and production scales up, hydrogen cars are poised to play a major role in the transition to clean transportation.

Whether you’re considering buying a hydrogen car or just curious about the technology, understanding how they’re made gives you a deeper appreciation for the innovation behind them. With continued investment and innovation, hydrogen-powered vehicles could soon become as common as electric cars—offering a fast-refueling, long-range, zero-emission alternative for drivers around the world.

Frequently Asked Questions

How long does it take to manufacture a hydrogen car?

The entire hydrogen car manufacturing process typically takes several days to a few weeks, depending on the model and factory setup. While some stages like MEA production are fast, final integration, testing, and quality control require careful attention to ensure safety and performance.

Are hydrogen cars safe to drive?

Yes, hydrogen cars are designed with multiple safety features, including leak detection, automatic shut-off valves, and crash-resistant tanks. Extensive testing ensures they meet or exceed safety standards for conventional vehicles.

Can hydrogen cars be repaired at regular auto shops?

Most repairs require specialized training and equipment due to the high-pressure hydrogen system and fuel cell technology. However, certified dealerships and service centers are being established to support growing fleets.

What happens if a hydrogen tank gets damaged?

Hydrogen tanks are built to withstand extreme conditions. In the rare event of damage, built-in sensors detect leaks and trigger safety systems to vent hydrogen safely or shut off the supply.

Is hydrogen car manufacturing more expensive than electric cars?

Currently, yes—due to the cost of fuel cells, hydrogen tanks, and low production volumes. However, as technology improves and scale increases, costs are expected to decrease significantly.

Can hydrogen cars use hydrogen produced from fossil fuels?

Yes, but it’s less sustainable. For true zero emissions, hydrogen should be produced using renewable energy (green hydrogen). Many manufacturers advocate for clean hydrogen to maximize environmental benefits.