Hydrogen fuel cell vehicle technology offers a zero-emission alternative to traditional gasoline cars by converting hydrogen into electricity. These vehicles produce only water as exhaust, making them a promising solution for sustainable transportation.

Key Takeaways

- Zero Emissions: Hydrogen fuel cell vehicles emit only water vapor, making them environmentally friendly and ideal for reducing urban air pollution.

- Fast Refueling: Unlike battery electric vehicles, hydrogen cars can be refueled in under 5 minutes, similar to gasoline vehicles.

- Long Driving Range: Most hydrogen-powered vehicles offer a range of 300–400 miles per tank, rivaling conventional cars.

- Energy Efficiency Challenges: Producing and transporting hydrogen is less efficient than direct electricity use, posing infrastructure and cost hurdles.

- Emerging Infrastructure: Refueling stations are limited but growing, especially in California, Japan, and parts of Europe.

- Government and Industry Support: Automakers like Toyota, Hyundai, and Honda are investing heavily, supported by national clean energy initiatives.

- Future Potential: As green hydrogen production scales up, fuel cell technology could play a major role in decarbonizing heavy transport and long-haul travel.

📑 Table of Contents

What Is Hydrogen Fuel Cell Vehicle Technology?

Imagine driving a car that runs on clean energy, refuels in minutes, and leaves behind nothing but water droplets. That’s the promise of hydrogen fuel cell vehicle technology—a cutting-edge innovation that’s quietly reshaping the future of transportation. Unlike traditional internal combustion engines that burn gasoline and emit harmful pollutants, hydrogen fuel cell vehicles (FCVs) generate electricity through a chemical reaction between hydrogen and oxygen. This process powers an electric motor, producing zero tailpipe emissions. The only byproduct? Pure water.

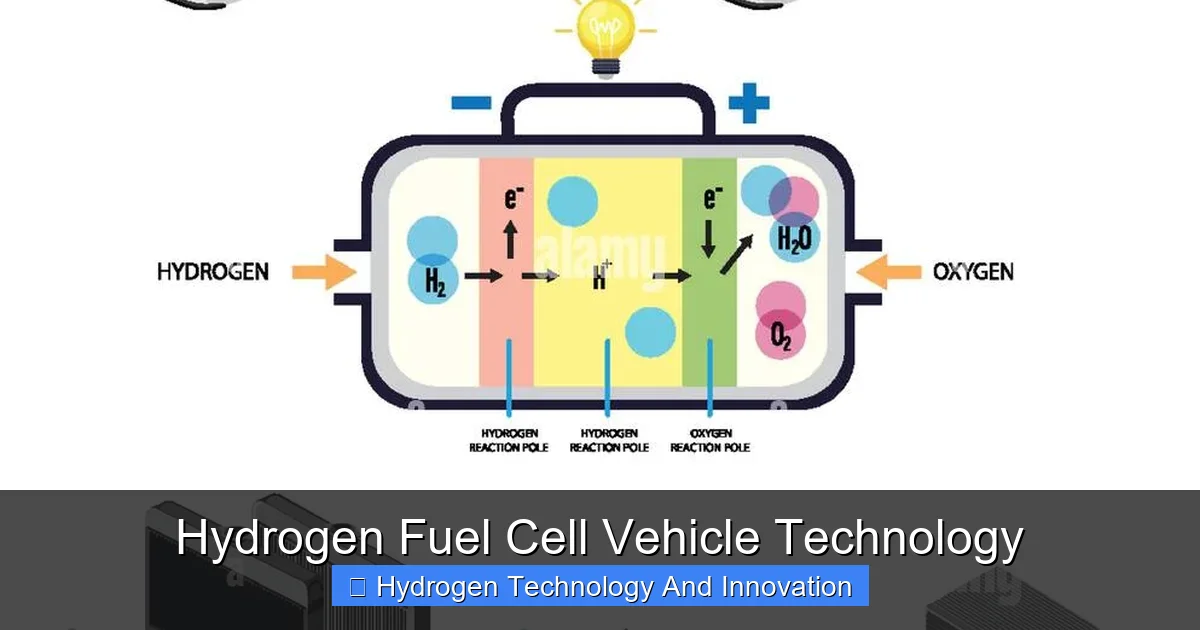

At the heart of this technology is the fuel cell stack—a series of individual fuel cells layered together like slices of bread in a sandwich. Each cell contains an anode, a cathode, and an electrolyte membrane. When hydrogen gas is fed into the anode, it splits into protons and electrons. The protons pass through the membrane to the cathode, while the electrons travel through an external circuit, creating an electric current. At the cathode, oxygen from the air combines with the protons and electrons to form water. This elegant, silent reaction is what powers the vehicle.

Hydrogen fuel cell vehicles are a subset of electric vehicles, but they differ from battery electric vehicles (BEVs) in how they store and generate energy. While BEVs rely on large, heavy batteries charged from the grid, FCVs carry compressed hydrogen gas in high-strength tanks and generate electricity on demand. This gives them unique advantages—especially for long-distance travel and heavy-duty applications—where battery weight and charging time become limiting factors.

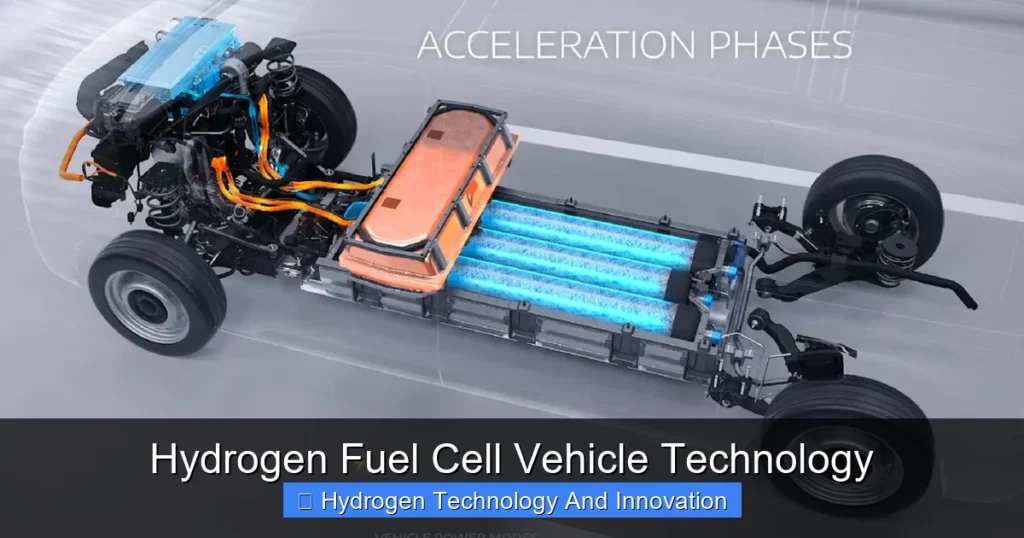

How Hydrogen Fuel Cell Vehicles Work

Visual guide about Hydrogen Fuel Cell Vehicle Technology

Image source: c8.alamy.com

To truly appreciate hydrogen fuel cell vehicle technology, it helps to understand the journey of hydrogen from tank to wheel. The process begins when hydrogen gas is stored in carbon-fiber-reinforced tanks at high pressure—typically around 700 bar (10,000 psi). These tanks are designed to be incredibly safe, with multiple layers and pressure relief devices to prevent leaks or ruptures.

When the driver presses the accelerator, hydrogen flows from the tank into the fuel cell stack. Inside each fuel cell, a catalyst—usually platinum—splits the hydrogen molecules into protons and electrons. The protons move through the proton exchange membrane (PEM) to the cathode side, while the electrons are forced to travel through an external electrical circuit. This flow of electrons generates the electricity needed to power the vehicle’s motor.

Meanwhile, air is drawn into the cathode side of the fuel cell, where oxygen reacts with the incoming protons and electrons to form water. This water exits the system as vapor through the exhaust—clean, odorless, and harmless. The entire process is silent, efficient, and emission-free at the point of use.

One of the key components enabling this reaction is the proton exchange membrane (PEM). This thin, polymer-based membrane allows only protons to pass through, blocking electrons and ensuring that the electrical current is directed where it’s needed. PEM fuel cells operate at relatively low temperatures (around 80°C), which allows for quick startup and responsiveness—ideal for everyday driving.

Another critical part of the system is the power control unit, which manages the flow of electricity between the fuel cell, the battery, and the motor. Most FCVs include a small lithium-ion battery to store excess energy and provide extra power during acceleration. This hybrid approach improves efficiency and helps recover energy during braking through regenerative systems.

The Role of the Electric Motor

Just like in battery electric vehicles, the electric motor in a hydrogen fuel cell vehicle converts electrical energy into mechanical motion. However, instead of drawing power from a large battery pack, the motor is primarily powered by the fuel cell stack. This setup offers smooth, quiet acceleration and instant torque—delivering a driving experience that feels both powerful and refined.

For example, the Toyota Mirai, one of the most well-known hydrogen cars, can go from 0 to 60 mph in about 9 seconds—comparable to many mid-size sedans. The Hyundai NEXO offers even quicker acceleration, reaching 60 mph in under 8 seconds, thanks to its optimized powertrain and lightweight design.

Energy Storage: Hydrogen Tanks

Storing hydrogen safely and efficiently is one of the biggest engineering challenges in fuel cell vehicle technology. Because hydrogen is the lightest element, it has low energy density by volume, even when compressed. That’s why FCVs use high-pressure tanks to store enough hydrogen for a practical driving range.

Modern hydrogen tanks are made from advanced composite materials, such as carbon fiber wrapped around aluminum or polymer liners. These tanks are rigorously tested for safety and can withstand extreme conditions, including crashes and fire exposure. In fact, studies have shown that hydrogen tanks are often safer than gasoline tanks in real-world accidents.

Each tank is equipped with a thermal pressure relief device (TPRD), which automatically vents hydrogen if the internal pressure or temperature rises too high—preventing explosions. Additionally, hydrogen is lighter than air, so any leaks tend to rise and dissipate quickly, reducing the risk of accumulation.

Benefits of Hydrogen Fuel Cell Vehicles

Hydrogen fuel cell vehicle technology offers a compelling set of advantages that make it a strong contender in the race toward sustainable transportation. While battery electric vehicles have gained widespread attention, FCVs bring unique strengths—especially in areas where BEVs face limitations.

One of the most significant benefits is zero tailpipe emissions. Unlike gasoline or diesel cars, hydrogen vehicles produce no carbon dioxide, nitrogen oxides, or particulate matter. The only emission is water vapor, which is harmless to the environment. This makes FCVs particularly valuable in urban areas struggling with air quality and smog.

Another major advantage is fast refueling. While charging a battery electric vehicle can take anywhere from 30 minutes (with fast chargers) to several hours, refueling a hydrogen car takes just 3 to 5 minutes—about the same as filling up a gas tank. This convenience is a game-changer for drivers who need to cover long distances or don’t have access to home charging.

Range is another strong point. Most hydrogen fuel cell vehicles offer a driving range of 300 to 400 miles on a single tank. The Toyota Mirai, for instance, has an EPA-estimated range of 402 miles—more than many BEVs on the market. This makes FCVs ideal for road trips, ride-sharing, and commercial applications where downtime must be minimized.

Environmental Impact

When it comes to environmental benefits, the full picture depends on how the hydrogen is produced. If hydrogen is made using renewable energy—such as solar or wind power—through a process called electrolysis, then the entire lifecycle of the vehicle can be nearly carbon-free. This “green hydrogen” is the gold standard for sustainability.

However, most hydrogen today is produced from natural gas through a method called steam methane reforming (SMR), which does release carbon dioxide. This “gray hydrogen” reduces the environmental advantage of FCVs. But even in these cases, studies show that hydrogen vehicles still produce fewer emissions than gasoline cars over their lifetime, especially when combined with carbon capture technologies.

As renewable energy becomes more affordable and widespread, the shift to green hydrogen is accelerating. Countries like Germany, Japan, and Australia are investing heavily in green hydrogen production, aiming to make it a cornerstone of their clean energy strategies.

Performance and Driving Experience

Driving a hydrogen fuel cell vehicle feels remarkably similar to driving a high-end electric car. The ride is smooth, quiet, and responsive, with no engine noise or gear shifts. The electric motor delivers instant torque, making acceleration feel effortless—even at low speeds.

Many FCVs also come equipped with advanced driver-assistance systems (ADAS), regenerative braking, and premium interiors. The Hyundai NEXO, for example, features a futuristic dashboard with dual 12.3-inch displays, augmented reality navigation, and a solar roof that helps power auxiliary systems.

For commercial and heavy-duty applications, hydrogen fuel cells offer even greater advantages. Trucks, buses, and trains that run on hydrogen can travel long distances without frequent stops, making them ideal for freight and public transit. Companies like Nikola and Toyota are already testing hydrogen-powered semi-trucks, with plans for widespread deployment in the coming years.

Challenges and Limitations

Despite their promise, hydrogen fuel cell vehicles face several significant challenges that have slowed their widespread adoption. Understanding these hurdles is key to appreciating the current state of the technology and what needs to happen for it to succeed.

One of the biggest obstacles is infrastructure. As of 2024, there are fewer than 100 hydrogen refueling stations in the United States, with most located in California. This limited network makes it difficult for drivers outside major metropolitan areas to own or operate an FCV. In contrast, electric vehicle charging stations are far more common, with tens of thousands of public chargers across the country.

Building a hydrogen refueling network is expensive. Each station can cost between $1 million and $3 million to construct, depending on size and location. Unlike electric chargers, which can be installed at homes, businesses, and parking lots, hydrogen stations require specialized equipment for compression, storage, and dispensing. They also need a reliable supply of hydrogen, which often means transporting it from centralized production facilities—adding to cost and complexity.

Cost of Hydrogen Production and Distribution

The cost of producing and delivering hydrogen remains high compared to gasoline or electricity. Currently, green hydrogen produced via electrolysis can cost $4 to $6 per kilogram, while gray hydrogen from natural gas is cheaper but still more expensive than fossil fuels on an energy-equivalent basis.

Transporting hydrogen is also challenging. Because it’s a small, light molecule, it can leak easily and embrittle metal pipes. It’s typically transported by truck in compressed or liquid form, which consumes energy and increases emissions. Pipelines are more efficient but require significant investment and regulatory approval.

Energy Efficiency Concerns

Another limitation is energy efficiency. When you compare the well-to-wheel efficiency of hydrogen fuel cell vehicles to battery electric vehicles, BEVs come out ahead. It takes about three times more energy to power an FCV than a BEV over the same distance.

Here’s why: producing hydrogen via electrolysis is only about 70–80% efficient. Compressing and transporting it loses another 10–15%. Then, converting hydrogen back into electricity in the fuel cell is about 60% efficient. Add it all up, and the total efficiency is around 30–35%. In contrast, charging a battery and driving an electric motor is over 75% efficient.

This doesn’t mean hydrogen is useless—it means it’s best suited for applications where batteries fall short, like long-haul trucking, aviation, or industrial processes. For passenger cars in urban areas, BEVs may still be the more efficient choice.

Public Perception and Safety Concerns

Hydrogen has a reputation for being dangerous, largely due to historical events like the Hindenburg disaster. While that incident involved a different type of hydrogen-filled airship and not modern fuel cells, the stigma persists.

In reality, hydrogen is no more dangerous than gasoline when handled properly. It’s flammable, but it disperses quickly in open air, reducing the risk of fire. Modern FCVs are designed with multiple safety systems, including leak detectors, automatic shutoff valves, and reinforced tanks.

Still, public education is needed to build trust. Many people don’t understand how hydrogen works or how safe it can be. Automakers and governments are working to improve awareness through demonstrations, safety campaigns, and transparent reporting.

Current Market and Leading Models

While hydrogen fuel cell vehicles are still a niche market, several automakers have made significant investments in the technology. The most prominent players include Toyota, Hyundai, and Honda—each offering production-ready models that are available for purchase or lease in select regions.

Toyota launched the Mirai in 2014, making it one of the first mass-produced hydrogen cars. The second-generation Mirai, introduced in 2020, features a sleeker design, improved range, and better efficiency. It’s available in the U.S., Japan, and parts of Europe, with a starting price around $50,000—though many buyers qualify for government incentives that reduce the cost significantly.

Hyundai’s NEXO, introduced in 2018, is another flagship model. It boasts a range of up to 380 miles and includes advanced features like solar roof panels and air-purifying filters. Hyundai has also partnered with companies like Cummins and Rimac to develop hydrogen-powered trucks and performance vehicles.

Honda offered the Clarity Fuel Cell from 2017 to 2021, though it has since paused production. The company remains committed to hydrogen technology and is exploring its use in larger vehicles and stationary power systems.

Commercial and Heavy-Duty Applications

While passenger cars get most of the attention, the real growth potential for hydrogen may lie in commercial and heavy-duty transport. Trucks, buses, and trains that travel long distances benefit greatly from hydrogen’s fast refueling and high energy density.

For example, Toyota is testing hydrogen-powered semi-trucks at the Port of Los Angeles, where they haul cargo between terminals and warehouses. These trucks can refuel in under 20 minutes and travel over 300 miles on a single tank—making them a viable alternative to diesel.

In Europe, companies like Alstom have introduced hydrogen-powered trains that emit only water and operate quietly in urban areas. These trains are already in service in Germany and are being considered for routes in the UK and France.

The Future of Hydrogen Fuel Cell Technology

The future of hydrogen fuel cell vehicle technology looks promising, but its success will depend on several key factors: infrastructure development, cost reduction, and policy support.

Governments around the world are beginning to recognize hydrogen’s potential. The U.S. Department of Energy has launched the Hydrogen Shot initiative, aiming to reduce the cost of clean hydrogen to $1 per kilogram within a decade. The European Union has included hydrogen in its Green Deal, with plans to install 40 gigawatts of electrolyzer capacity by 2030.

Private companies are also stepping up. Shell, BP, and Air Liquide are investing in hydrogen refueling networks and production facilities. Automakers are forming partnerships to share technology and reduce costs—such as the collaboration between Toyota and BMW on fuel cell systems.

Green Hydrogen and Renewable Integration

The shift to green hydrogen—produced using renewable energy—is critical for the long-term viability of fuel cell vehicles. As solar and wind power become cheaper and more abundant, excess electricity can be used to split water into hydrogen and oxygen via electrolysis. This hydrogen can then be stored and used when needed, providing a way to balance the grid and reduce curtailment.

In regions with abundant renewable resources—like Australia, Chile, and the Middle East—green hydrogen production is scaling rapidly. These areas could become major exporters of hydrogen, supplying fuel for vehicles, industry, and power generation worldwide.

Integration with Other Technologies

Hydrogen fuel cell technology doesn’t have to compete with battery electric vehicles—it can complement them. In a diversified clean transportation ecosystem, BEVs may dominate urban and short-range travel, while FCVs handle long-haul, heavy-duty, and high-utilization applications.

Smart charging, vehicle-to-grid (V2G) systems, and hydrogen production from waste or biomass could further enhance the sustainability of both technologies. The key is to use the right tool for the right job.

Conclusion

Hydrogen fuel cell vehicle technology represents a bold step toward a cleaner, more sustainable future. With zero emissions, fast refueling, and long range, FCVs offer a compelling alternative to both gasoline and battery electric vehicles—especially in applications where batteries fall short.

While challenges remain—particularly in infrastructure, cost, and energy efficiency—the momentum is building. Governments, automakers, and energy companies are investing billions in hydrogen research and deployment. As green hydrogen production scales up and refueling networks expand, hydrogen-powered transportation could become a common sight on roads around the world.

The journey is just beginning, but the destination is clear: a world where clean energy powers our vehicles, protects our planet, and improves our quality of life. Whether you’re a driver, a policymaker, or simply someone who cares about the future, hydrogen fuel cell technology is worth watching—and supporting.

Frequently Asked Questions

How does a hydrogen fuel cell vehicle produce electricity?

A hydrogen fuel cell vehicle generates electricity through a chemical reaction between hydrogen and oxygen inside a fuel cell stack. Hydrogen is split into protons and electrons at the anode, and the electrons create an electric current that powers the motor, while the protons move to the cathode to form water.

Are hydrogen fuel cell vehicles safe?

Yes, hydrogen fuel cell vehicles are designed with multiple safety features, including high-strength tanks, leak detectors, and automatic shutoff valves. Hydrogen disperses quickly in air, reducing fire risk, and modern FCVs undergo rigorous crash and safety testing.

How long does it take to refuel a hydrogen car?

Refueling a hydrogen fuel cell vehicle takes about 3 to 5 minutes, similar to filling up a gasoline car. This is much faster than charging most battery electric vehicles, which can take 30 minutes to several hours depending on the charger.

Where can I refuel a hydrogen vehicle?

Hydrogen refueling stations are currently limited, with most located in California, Japan, South Korea, and parts of Europe. The network is growing, but availability outside major urban areas remains sparse.

What is green hydrogen, and why is it important?

Green hydrogen is produced using renewable energy (like solar or wind) to split water into hydrogen and oxygen via electrolysis. It’s important because it creates a truly zero-emission fuel cycle, making hydrogen vehicles as clean as possible from production to use.

Can hydrogen fuel cells be used in trucks and buses?

Yes, hydrogen fuel cells are especially well-suited for heavy-duty vehicles like trucks, buses, and trains. Their fast refueling and long range make them ideal for commercial and public transportation, where battery weight and charging time are limiting factors.