Hydrogen fuel cell vehicles (FCEVs) offer a promising zero-emission alternative to traditional cars and trucks, powered by clean energy from renewable hydrogen production. By combining advanced fuel cell technology with green hydrogen made from solar, wind, and water, we can drastically reduce transportation emissions and dependence on fossil fuels.

Imagine driving a car that emits nothing but water vapor—no smog, no greenhouse gases, just clean air behind you. That’s the promise of hydrogen fuel cell vehicles (FCEVs), a cutting-edge technology that’s gaining momentum as the world seeks sustainable alternatives to fossil fuels. Unlike battery electric vehicles (BEVs), which store electricity in large batteries, FCEVs generate their own power on board using hydrogen gas and oxygen from the air. The result? A quiet, smooth ride with zero tailpipe emissions and a refueling experience that takes just minutes—similar to filling up a gas tank.

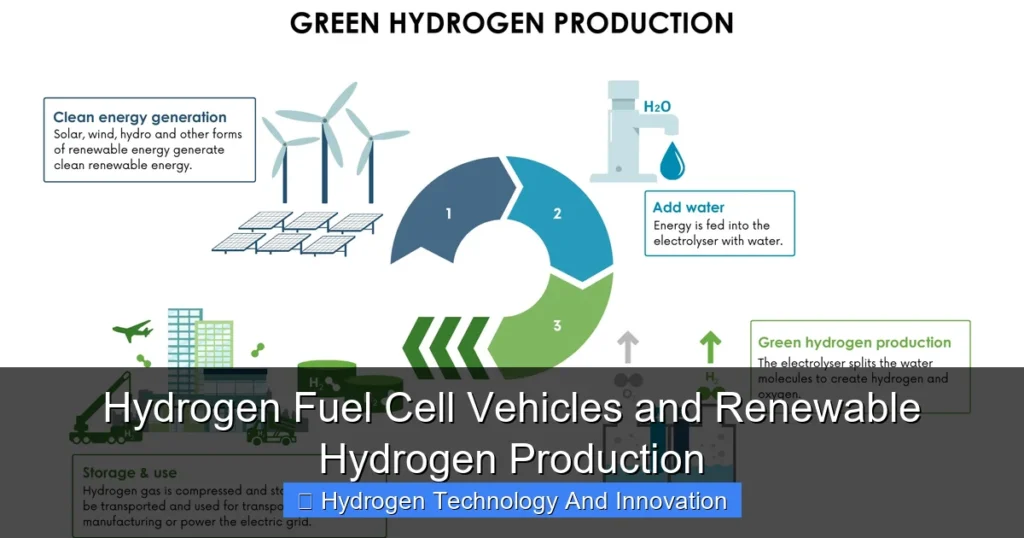

But here’s the catch: for hydrogen vehicles to truly be “green,” the hydrogen itself must be produced using renewable energy. This is where renewable hydrogen production comes into play. Instead of extracting hydrogen from natural gas—a process that releases carbon dioxide—renewable hydrogen is made by splitting water molecules using electricity from solar panels, wind turbines, or other clean sources. This method, known as electrolysis, produces what’s called “green hydrogen,” a truly sustainable fuel that can power not just cars, but buses, trucks, trains, and even ships.

The synergy between hydrogen fuel cell vehicles and renewable hydrogen production represents a major leap forward in the fight against climate change. As countries around the world commit to net-zero emissions targets, hydrogen is emerging as a key player in decarbonizing sectors that are hard to electrify with batteries alone. From long-haul freight to industrial heating, hydrogen offers a versatile, scalable solution. And with advancements in fuel cell efficiency, storage technology, and renewable energy integration, the dream of a hydrogen-powered future is becoming more tangible every day.

Key Takeaways

- Hydrogen fuel cell vehicles produce zero tailpipe emissions, emitting only water vapor and warm air, making them a clean alternative to gasoline and diesel vehicles.

- Renewable hydrogen is produced using clean energy sources like wind, solar, and hydropower through a process called electrolysis, splitting water into hydrogen and oxygen.

- FCEVs offer fast refueling and long driving ranges, often comparable to conventional vehicles, with some models exceeding 300 miles per tank.

- Hydrogen infrastructure is expanding slowly but steadily, with growing investment in refueling stations, especially in California, Japan, and Europe.

- Green hydrogen can decarbonize heavy industries and transport, including shipping, aviation, and long-haul trucking, where batteries face limitations.

- Challenges remain in cost, storage, and scalability, but ongoing innovation and policy support are driving progress toward a hydrogen-powered future.

- Consumers can support the transition by staying informed and advocating for clean energy policies that promote renewable hydrogen and FCEV adoption.

📑 Table of Contents

How Hydrogen Fuel Cell Vehicles Work

At the heart of every hydrogen fuel cell vehicle is a device called a fuel cell stack. This stack combines hydrogen gas from the vehicle’s onboard tank with oxygen from the air to produce electricity, water, and heat. The electricity powers the car’s motor, while the only byproduct—water vapor—exits through the tailpipe. It’s a clean, quiet, and efficient process that mirrors the principles of a battery, but without the need for constant recharging.

The Fuel Cell Stack: Power from Chemistry

The fuel cell stack is made up of hundreds of individual fuel cells layered together. Each cell contains an anode, a cathode, and an electrolyte membrane. When hydrogen gas enters the anode, a catalyst—usually platinum—splits the hydrogen atoms into protons and electrons. The protons pass through the electrolyte membrane to the cathode, while the electrons are forced to travel through an external circuit, creating an electric current. At the cathode, the protons, electrons, and oxygen from the air combine to form water. This electrochemical reaction generates the electricity needed to drive the vehicle.

Hydrogen Storage: Safe and Efficient

Storing hydrogen safely and efficiently is a key challenge in FCEV design. Most hydrogen fuel cell vehicles use high-pressure tanks that store hydrogen gas at around 700 bar (10,000 psi)—roughly 30 times the pressure of a typical car tire. These tanks are made from advanced composite materials like carbon fiber, which are lightweight yet incredibly strong. Modern FCEVs are designed with multiple safety systems, including pressure relief devices and leak detection sensors, to ensure safe operation even in the event of a collision.

Performance and Refueling Experience

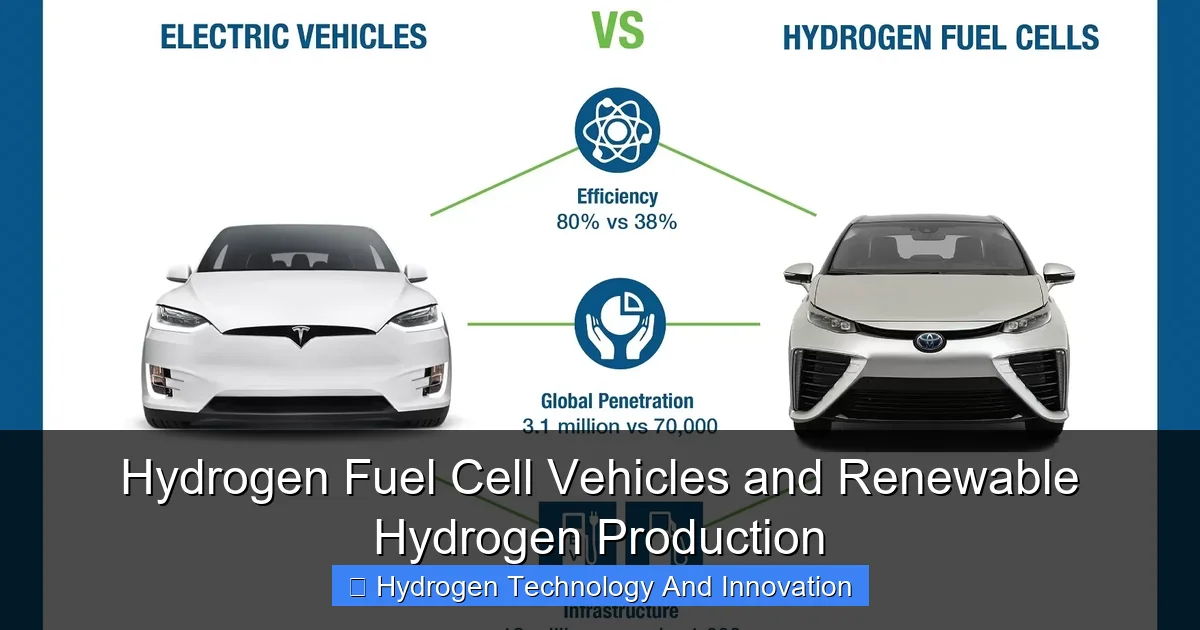

One of the biggest advantages of FCEVs over battery electric vehicles is refueling time. While BEVs can take 30 minutes to several hours to recharge, hydrogen vehicles can be refueled in just 3 to 5 minutes—similar to gasoline cars. This makes FCEVs especially appealing for long-distance travel and commercial applications like taxis and delivery trucks. Additionally, many FCEVs offer driving ranges of 300 to 400 miles on a single tank, rivaling conventional vehicles and outperforming many electric models.

Renewable Hydrogen Production: The Green Fuel Source

For hydrogen to be a truly sustainable fuel, it must be produced using renewable energy. This is where renewable hydrogen production comes in—a process that uses clean electricity to split water into hydrogen and oxygen. Unlike “gray hydrogen,” which is derived from natural gas and emits CO₂, or “blue hydrogen,” which captures some of those emissions, renewable (or “green”) hydrogen is carbon-free from start to finish.

Electrolysis: Splitting Water with Clean Energy

The most common method for producing renewable hydrogen is electrolysis. In this process, an electrolyzer uses electricity to split water (H₂O) into its component parts: hydrogen (H₂) and oxygen (O₂). The hydrogen is then compressed and stored for use in fuel cells, while the oxygen is typically released into the atmosphere or used in industrial applications. When the electricity comes from renewable sources like solar, wind, or hydropower, the entire process is emissions-free.

Visual guide about Hydrogen Fuel Cell Vehicles and Renewable Hydrogen Production

Image source: evse.com.au

Types of Electrolyzers

There are several types of electrolyzers used in renewable hydrogen production, each with its own advantages:

- Alkaline Electrolyzers: Mature and cost-effective, these are widely used in industrial applications. They use a liquid alkaline solution as the electrolyte and operate at moderate temperatures.

- Proton Exchange Membrane (PEM) Electrolyzers: More compact and responsive, PEM electrolyzers use a solid polymer membrane and can quickly adjust to variable renewable energy inputs, making them ideal for solar and wind-powered systems.

- Solid Oxide Electrolyzers (SOEC): Highly efficient but still in development, SOECs operate at high temperatures and can use waste heat from industrial processes, further improving energy efficiency.

Integration with Renewable Energy Grids

One of the most exciting aspects of renewable hydrogen production is its potential to store excess renewable energy. Solar and wind power are intermittent—they generate electricity only when the sun shines or the wind blows. By using surplus energy to produce hydrogen, we can store that energy for later use, whether in vehicles, industrial processes, or even feeding it back into the grid during peak demand. This makes hydrogen a valuable tool for grid stability and energy resilience.

Current Applications and Real-World Examples

Hydrogen fuel cell vehicles are no longer a futuristic concept—they’re already on the roads today. From passenger cars to heavy-duty trucks, FCEVs are being deployed in various sectors, demonstrating their viability and benefits.

Passenger Vehicles: Toyota Mirai and Hyundai NEXO

The Toyota Mirai and Hyundai NEXO are two of the most well-known hydrogen fuel cell cars available to consumers. The Mirai, first launched in 2014, has undergone significant improvements, with the latest model offering over 400 miles of range and a sleek, modern design. The Hyundai NEXO, meanwhile, boasts advanced driver assistance features and a refined interior. Both vehicles are currently available in limited markets, primarily California, where hydrogen refueling infrastructure is most developed.

Public Transit and Commercial Fleets

Cities around the world are adopting hydrogen-powered buses to reduce urban air pollution. For example, London operates a fleet of hydrogen double-decker buses that emit only water vapor, improving air quality in densely populated areas. Similarly, companies like Amazon and UPS are testing hydrogen fuel cell delivery trucks for their logistics fleets. These vehicles offer the long range and quick refueling needed for daily operations, without the downtime associated with battery charging.

Heavy-Duty and Long-Haul Transport

One of the most promising applications for hydrogen is in heavy-duty transportation. Trucks, trains, and ships require high energy density and long range—areas where batteries struggle due to weight and charging limitations. Companies like Nikola and Hyundai are developing hydrogen-powered semi-trucks that can travel over 500 miles on a single tank. In Europe, Alstom’s hydrogen-powered trains, known as Coradia iLint, are already operating on non-electrified rail lines, offering a clean alternative to diesel locomotives.

Challenges and Barriers to Adoption

Despite their potential, hydrogen fuel cell vehicles and renewable hydrogen production face several challenges that must be addressed for widespread adoption.

High Production and Infrastructure Costs

One of the biggest hurdles is cost. Producing green hydrogen is currently more expensive than gray hydrogen due to the high price of electrolyzers and renewable electricity. Additionally, building a nationwide network of hydrogen refueling stations requires significant investment. As of 2024, there are fewer than 100 public hydrogen stations in the United States, mostly concentrated in California. Expanding this infrastructure will require public-private partnerships and government incentives.

Energy Efficiency and Storage Challenges

Hydrogen production, compression, and conversion back to electricity are less efficient than direct battery use. The “well-to-wheel” efficiency of hydrogen vehicles is typically around 25–35%, compared to 70–90% for battery electric vehicles. Additionally, hydrogen is a lightweight gas that requires high-pressure storage or cryogenic temperatures to liquefy, posing engineering and safety challenges.

Public Awareness and Policy Support

Many consumers are still unfamiliar with hydrogen vehicles and their benefits. Misconceptions about safety—fueled by outdated images of the Hindenburg disaster—persist, even though modern hydrogen systems are rigorously tested and safe. Stronger public education campaigns and supportive policies, such as tax credits, grants, and renewable hydrogen mandates, are essential to accelerate adoption.

The Future of Hydrogen: Innovation and Growth

The future of hydrogen fuel cell vehicles and renewable hydrogen production looks bright, driven by technological innovation, falling renewable energy costs, and growing climate commitments.

Advancements in Fuel Cell Technology

Researchers are working to reduce the cost and improve the durability of fuel cells. New catalysts made from non-precious metals could lower production costs, while advances in membrane materials are increasing efficiency and lifespan. Solid-state hydrogen storage, which stores hydrogen in metal hydrides or chemical compounds, could also make vehicles safer and more compact.

Scaling Up Renewable Hydrogen Production

Countries like Germany, Japan, and Australia are investing billions in large-scale green hydrogen projects. For example, the HyDeal Ambition initiative in Europe aims to produce green hydrogen at scale by 2030, targeting costs below $2 per kilogram—making it competitive with fossil fuels. In the U.S., the Department of Energy’s “Hydrogen Shot” initiative aims to reduce the cost of clean hydrogen to $1 per kilogram within a decade.

Integration with a Clean Energy Economy

Hydrogen is increasingly seen as a cornerstone of a decarbonized energy system. It can be used not only for transportation but also for industrial processes, heating, and long-term energy storage. By linking renewable hydrogen production with hydrogen fuel cell vehicles, we can create a circular, sustainable energy ecosystem that reduces reliance on fossil fuels and cuts greenhouse gas emissions across multiple sectors.

How You Can Get Involved

You don’t have to wait for a hydrogen-powered future—you can help shape it today.

Stay Informed and Advocate

Learn more about hydrogen technology and share accurate information with friends and family. Support policies that promote renewable energy, clean transportation, and hydrogen infrastructure. Contact your representatives to express support for green hydrogen initiatives and FCEV incentives.

Consider a Hydrogen Vehicle (When Available)

If you live in an area with hydrogen refueling stations, consider test-driving a Toyota Mirai or Hyundai NEXO. Your experience can help drive demand and encourage further investment in the technology.

Support Renewable Energy

Whether through rooftop solar, community solar programs, or choosing a green energy provider, supporting renewable electricity helps make green hydrogen production more viable and affordable.

The journey toward a hydrogen-powered future is just beginning, but the pieces are falling into place. With continued innovation, investment, and public support, hydrogen fuel cell vehicles and renewable hydrogen production can play a central role in building a cleaner, more sustainable world.

Frequently Asked Questions

Are hydrogen fuel cell vehicles safe?

Yes, hydrogen fuel cell vehicles are designed with multiple safety features, including high-strength storage tanks, leak detection systems, and automatic shut-off valves. Modern FCEVs undergo rigorous testing and are as safe as conventional vehicles.

How is renewable hydrogen different from regular hydrogen?

Renewable hydrogen, also known as green hydrogen, is produced using clean electricity from sources like wind and solar to split water into hydrogen and oxygen. Regular (gray) hydrogen is typically made from natural gas and releases carbon dioxide in the process.

Can I refuel a hydrogen car at home?

Currently, home refueling is not widely available. Most hydrogen refueling stations are public and located in urban areas, primarily in California. Home systems are being developed but are not yet common due to cost and safety regulations.

How long does it take to refuel a hydrogen vehicle?

Refueling a hydrogen fuel cell vehicle takes about 3 to 5 minutes, similar to filling up a gasoline car. This is much faster than charging most electric vehicles, making FCEVs ideal for long trips and commercial use.

What is the range of a hydrogen fuel cell vehicle?

Most hydrogen fuel cell vehicles offer a driving range of 300 to 400 miles on a single tank, with some models like the Toyota Mirai exceeding 400 miles. This range is comparable to many gasoline-powered cars.

Is hydrogen production bad for the environment?

It depends on the method. Green hydrogen, produced with renewable energy, is environmentally friendly. However, gray hydrogen, made from fossil fuels, contributes to carbon emissions. The shift to renewable hydrogen is key to sustainability.