Hydrogen refueling station maintenance is critical for safety, reliability, and performance. Regular inspections, component monitoring, and adherence to strict protocols help prevent leaks, ensure compliance, and extend equipment life. Proper training and documentation are key to maintaining a safe and efficient hydrogen infrastructure.

Key Takeaways

- Routine inspections are essential: Daily, weekly, and monthly checks help detect wear, leaks, or malfunctions early.

- Component-specific maintenance matters: Compressors, storage tanks, dispensers, and cooling systems each require tailored care.

- Safety protocols cannot be overlooked: Hydrogen’s flammability and low ignition energy demand strict handling procedures.

- Staff training is non-negotiable: Technicians must be certified and up-to-date on hydrogen safety and equipment operation.

- Documentation supports compliance: Detailed logs of maintenance, repairs, and inspections ensure regulatory adherence and operational transparency.

- Preventive over reactive maintenance: Scheduled upkeep reduces downtime and costly emergency repairs.

- Environmental monitoring enhances safety: Gas detectors, ventilation, and weatherproofing protect both equipment and personnel.

📑 Table of Contents

Introduction to Hydrogen Refueling Station Maintenance

As the world shifts toward cleaner energy solutions, hydrogen-powered vehicles are gaining momentum. From buses and trucks to passenger cars and forklifts, fuel cell electric vehicles (FCEVs) are becoming a viable alternative to traditional internal combustion engines. At the heart of this green revolution lies the hydrogen refueling station—a complex, high-tech infrastructure that must operate safely and efficiently around the clock.

But here’s the catch: hydrogen is not your average fuel. It’s the lightest and most abundant element in the universe, but it’s also highly flammable, prone to leakage, and requires extreme pressure or cryogenic temperatures for storage. This makes maintaining a hydrogen refueling station a unique challenge. Unlike gasoline or diesel pumps, hydrogen stations involve high-pressure systems, sensitive sensors, and specialized components that demand precision care. Neglecting maintenance can lead to equipment failure, safety hazards, or costly downtime.

Why Maintenance Matters in Hydrogen Infrastructure

Hydrogen refueling stations are critical nodes in the emerging clean transportation network. They must deliver hydrogen safely, quickly, and reliably—just like any conventional fueling station. However, the stakes are higher due to hydrogen’s physical and chemical properties. A single oversight in maintenance can result in leaks, fires, or even explosions, putting both operators and the public at risk.

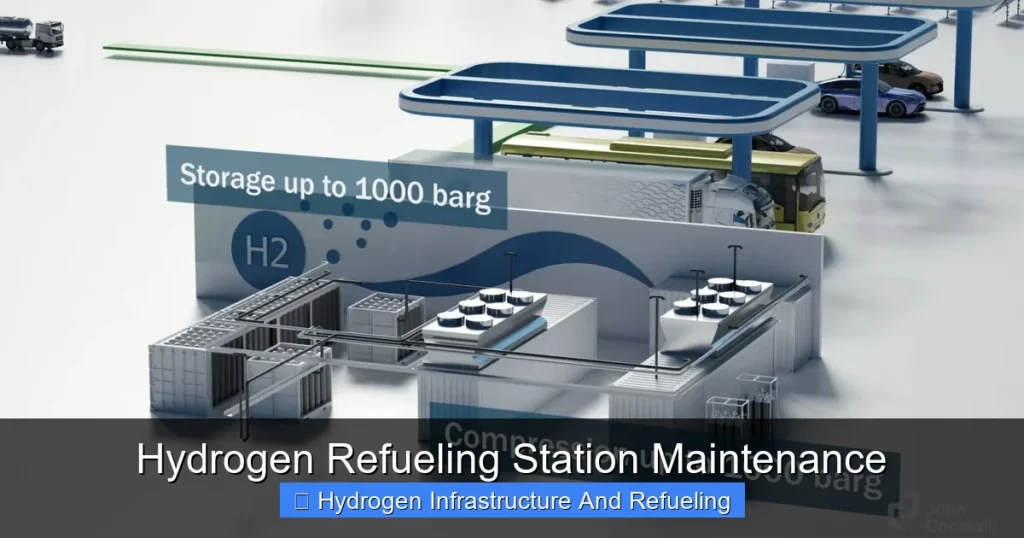

Visual guide about Hydrogen Refueling Station Maintenance

Image source: energynews.biz

Beyond safety, regular maintenance ensures operational efficiency. A well-maintained station minimizes downtime, reduces energy consumption, and extends the lifespan of expensive equipment. It also helps maintain customer trust. Imagine a driver arriving at a hydrogen station only to find it out of service—frustrating, right? Consistent uptime builds confidence in hydrogen as a practical fuel option.

The Cost of Neglect

Consider a real-world example: a station in California experienced a compressor failure due to inadequate lubrication. The repair took three days and cost over $50,000 in parts and labor. Worse, the station lost revenue and damaged its reputation with local fleet operators. This could have been avoided with a simple monthly inspection of the compressor’s oil levels and filter condition.

Another common issue is seal degradation. Hydrogen molecules are tiny and can escape through microscopic gaps in seals and gaskets. Over time, exposure to high pressure and temperature cycles weakens these components. Without routine replacement, leaks develop—often undetected until a sensor triggers an alarm. Early detection through scheduled maintenance prevents such scenarios.

Regulatory and Compliance Drivers

Maintenance isn’t just about performance—it’s also about compliance. Hydrogen stations must adhere to strict regulations set by organizations like the National Fire Protection Association (NFPA), the International Code Council (ICC), and local authorities having jurisdiction (AHJs). These standards cover everything from equipment installation to emergency shutdown procedures.

For instance, NFPA 2: Hydrogen Technologies Code outlines detailed requirements for station design, operation, and maintenance. It mandates regular testing of pressure relief devices, leak detection systems, and emergency ventilation. Failure to comply can result in fines, shutdowns, or legal liability in the event of an incident.

Core Components Requiring Maintenance

A hydrogen refueling station is made up of several interconnected systems, each playing a vital role in the fueling process. Understanding these components—and how to maintain them—is essential for station operators and technicians.

Hydrogen Compressors

Compressors are the workhorses of a hydrogen station. They take low-pressure hydrogen (often from on-site production or delivery trucks) and compress it to high pressures—typically 350 bar (5,000 psi) or 700 bar (10,000 psi)—for storage and dispensing. These machines operate under extreme stress and require careful attention.

Maintenance tasks include checking oil levels, replacing filters, inspecting valves, and monitoring vibration levels. Oil contamination is a common issue—dirt or moisture can degrade lubrication and damage internal parts. Technicians should follow the manufacturer’s recommended service intervals, which may range from 500 to 2,000 operating hours.

Tip: Use oil analysis kits to test for water content, acidity, and particulate matter. This helps predict when an oil change is needed, preventing unexpected failures.

High-Pressure Storage Tanks

Storage tanks hold compressed hydrogen until it’s needed for refueling. These vessels are built to withstand immense pressure, but they’re not invincible. Over time, metal fatigue, corrosion, or improper handling can compromise their integrity.

Routine inspections should include visual checks for dents, rust, or paint degradation. Ultrasonic thickness testing can detect thinning walls, a sign of internal wear. Pressure relief devices (PRDs) must be tested annually to ensure they activate at the correct pressure.

Example: A station in Germany avoided a potential rupture by catching a hairline crack during a scheduled ultrasonic scan. The tank was replaced before any hydrogen escaped.

Dispensers and Hoses

The dispenser is the customer-facing part of the station—the nozzle you connect to your vehicle. But it’s also a complex piece of equipment with valves, sensors, and thermal management systems. Hoses, in particular, are prone to wear from repeated use and environmental exposure.

Inspect hoses for cracks, bulges, or kinks. Replace them every 2–3 years or sooner if damage is detected. Check nozzle seals for wear—hydrogen can escape through even the smallest gap. Also, verify that the dispenser’s temperature sensors are calibrated correctly. Hydrogen expands when heated, so accurate temperature readings are crucial for correct fueling.

Pro tip: Keep spare hoses and nozzles on hand. A damaged hose can shut down a dispenser for hours if replacements aren’t available.

Cooling and Thermal Management Systems

Hydrogen heats up during compression and rapid dispensing. If not cooled, it can exceed safe temperature limits, triggering shutdowns or safety alarms. Most stations use chillers or heat exchangers to maintain optimal gas temperature.

Maintenance involves cleaning condenser coils, checking refrigerant levels, and inspecting coolant pumps. Clogged coils reduce efficiency and increase energy use. In colder climates, antifreeze levels must be monitored to prevent freezing.

Case in point: A station in Canada experienced repeated shutdowns in winter. The issue? Frozen coolant lines. After installing insulation and a freeze protection system, the problem was resolved.

Leak Detection and Gas Monitoring

Hydrogen is odorless, colorless, and invisible—making leaks hard to detect without specialized equipment. That’s why every station must have a network of hydrogen sensors and gas detectors.

These devices should be tested monthly using certified hydrogen test gas. Calibration ensures they respond accurately to low concentrations (typically 1–2% of the lower explosive limit). Also, inspect sensor placement—dead zones where gas might accumulate should be avoided.

Tip: Install sensors at multiple heights. Hydrogen rises, so place some near the ceiling and others at ground level to catch leaks from different sources.

Safety Protocols and Best Practices

Safety is the top priority in hydrogen refueling station maintenance. Even small mistakes can have serious consequences. That’s why strict protocols must be followed at all times.

Personal Protective Equipment (PPE)

Technicians should always wear appropriate PPE, including flame-resistant clothing, safety glasses, and gloves. In high-risk areas, face shields and respirators may be required. Never wear synthetic fabrics—they can melt and cause severe burns.

Also, ensure that all tools are non-sparking. Hydrogen can ignite from a simple static discharge, so use brass or aluminum tools when working near hydrogen systems.

Lockout/Tagout (LOTO) Procedures

Before performing any maintenance, isolate energy sources using lockout/tagout procedures. This means shutting off power, depressurizing lines, and locking valves in the closed position. Tag each lock with the technician’s name and date.

LOTO prevents accidental startup or release of hydrogen during repairs. It’s a simple step that has prevented countless accidents in industrial settings.

Ventilation and Explosion Protection

Hydrogen stations must have adequate ventilation to disperse any leaked gas. Roof vents, exhaust fans, and open designs help prevent accumulation. In enclosed areas, explosion-proof electrical equipment is mandatory.

Regularly inspect ventilation systems for blockages or damage. Ensure that emergency fans activate automatically when a leak is detected.

Emergency Response Planning

Even with the best maintenance, emergencies can happen. Stations must have a clear response plan, including evacuation routes, fire suppression systems, and communication protocols.

Train staff on how to respond to leaks, fires, or injuries. Conduct drills twice a year. Keep emergency contact numbers posted and ensure first aid kits are accessible.

Preventive vs. Reactive Maintenance

There are two approaches to maintenance: reactive (fixing things after they break) and preventive (keeping things from breaking in the first place). For hydrogen stations, preventive maintenance is far superior.

The Case for Preventive Maintenance

Preventive maintenance involves scheduled inspections, part replacements, and system checks based on time or usage. It’s proactive, cost-effective, and reduces the risk of unexpected failures.

For example, replacing a filter every 1,000 hours may cost $200. But if that filter clogs and causes a compressor failure, the repair could cost $10,000 and take days to complete. The math is clear.

Building a Maintenance Schedule

A good maintenance plan includes daily, weekly, monthly, and annual tasks. Here’s a sample schedule:

- Daily: Visual inspection of dispensers, check for leaks, verify sensor readings.

- Weekly: Test emergency shutdown systems, inspect hoses and seals.

- Monthly: Calibrate sensors, check compressor oil, inspect storage tanks.

- Annually: Pressure test tanks, replace PRDs, conduct full system audit.

Use digital maintenance software to track tasks, set reminders, and generate reports. This improves accountability and ensures nothing is missed.

Condition-Based Monitoring

Beyond time-based schedules, consider condition-based monitoring. Use sensors to track vibration, temperature, pressure, and flow rates in real time. If values deviate from normal, the system alerts technicians before a failure occurs.

For instance, a sudden spike in compressor vibration could indicate bearing wear. Addressing it early prevents a catastrophic breakdown.

Training and Documentation

Even the best maintenance plan fails without skilled personnel and proper records.

Technician Training

All maintenance staff should be trained and certified in hydrogen safety. Programs like the Hydrogen Safety Training for Emergency Responders (H2Safety) or manufacturer-specific courses provide essential knowledge.

Training should cover hydrogen properties, equipment operation, emergency procedures, and hands-on practice. Refresher courses should be held annually.

Documentation and Recordkeeping

Keep detailed logs of all maintenance activities. Include dates, tasks performed, parts replaced, and technician names. This supports compliance audits and helps identify recurring issues.

Digital records are preferred—they’re easier to search, backup, and share. Some systems even integrate with regulatory reporting tools.

Incident Reporting

If a leak, malfunction, or near-miss occurs, document it immediately. Analyze the root cause and update procedures to prevent recurrence. Sharing lessons learned across your network improves overall safety.

Future Trends in Hydrogen Station Maintenance

The hydrogen industry is evolving rapidly, and maintenance practices are keeping pace.

Remote Monitoring and AI

New stations are equipped with IoT sensors that transmit data to cloud platforms. Artificial intelligence analyzes trends and predicts failures before they happen. This “predictive maintenance” reduces downtime and optimizes resource use.

Modular and Standardized Designs

Manufacturers are developing modular stations with interchangeable components. This simplifies maintenance—technicians can swap out a faulty module instead of repairing it on-site.

Automated Leak Detection

Advanced systems use laser spectroscopy or acoustic sensors to detect leaks with pinpoint accuracy. Some can even locate the source within seconds.

Conclusion

Hydrogen refueling station maintenance is not just a technical task—it’s a commitment to safety, reliability, and sustainability. As hydrogen vehicles become more common, the demand for well-maintained stations will only grow. By following best practices, investing in training, and embracing new technologies, operators can ensure their stations operate smoothly and safely for years to come.

Remember, maintenance is not an expense—it’s an investment. A few hours of preventive care today can prevent a major incident tomorrow. Stay proactive, stay informed, and keep the hydrogen flowing.

Frequently Asked Questions

How often should a hydrogen refueling station be inspected?

Hydrogen refueling stations should undergo daily visual checks, weekly system tests, monthly component inspections, and annual comprehensive audits. High-use stations may require more frequent servicing.

What are the most common maintenance issues at hydrogen stations?

Common issues include compressor oil contamination, seal degradation, hose wear, sensor calibration drift, and clogged cooling systems. Regular inspections help catch these early.

Can hydrogen leaks be detected without special equipment?

No. Hydrogen is invisible and odorless, so leaks cannot be detected by sight or smell. Specialized gas detectors and sensors are required for safe monitoring.

Is it safe to perform maintenance on a hydrogen station?

Yes, when proper safety protocols are followed. This includes using PPE, lockout/tagout procedures, and working in well-ventilated areas. Only trained personnel should perform maintenance.

What happens if a hydrogen station fails inspection?

If a station fails inspection, it may be required to shut down until repairs are made. Operators must address deficiencies and pass a re-inspection before resuming operations.

How can I reduce maintenance costs at a hydrogen station?

Focus on preventive maintenance, use condition-based monitoring, train staff thoroughly, and keep detailed records. This reduces emergency repairs and extends equipment life.