Hydrogen car engines are evolving rapidly, offering zero-emission transportation with innovations in fuel cells, storage, and infrastructure. From improved efficiency to faster refueling, these breakthroughs are making hydrogen vehicles more practical and sustainable than ever before.

Key Takeaways

- Hydrogen fuel cells are becoming more efficient and affordable, thanks to advances in materials and manufacturing processes.

- New storage technologies allow safer, lighter hydrogen tanks, improving vehicle range and safety standards.

- Green hydrogen production using renewable energy is reducing the carbon footprint of hydrogen-powered vehicles.

- Refueling infrastructure is expanding globally, with more hydrogen stations being built in key markets like Europe, Japan, and California.

- Automakers are investing heavily in hydrogen models, including sedans, SUVs, and heavy-duty trucks, signaling long-term industry commitment.

- Hybrid hydrogen-electric systems are emerging as a bridge technology, combining the best of both powertrains.

- Government policies and incentives are accelerating adoption, supporting research and consumer adoption.

📑 Table of Contents

- Introduction: The Rise of Hydrogen-Powered Vehicles

- How Hydrogen Car Engines Work: A Simple Breakdown

- Breakthroughs in Fuel Cell Technology

- Advances in Hydrogen Storage Solutions

- Green Hydrogen: The Clean Fuel Revolution

- Infrastructure and Refueling Innovations

- Automaker Commitment and Real-World Applications

- The Road Ahead: Challenges and Opportunities

- Conclusion: A Hydrogen-Powered Future Is Closer Than You Think

Introduction: The Rise of Hydrogen-Powered Vehicles

Imagine driving a car that emits nothing but water vapor—no smog, no greenhouse gases, just clean air behind you. That’s the promise of hydrogen car engines, and it’s no longer science fiction. While electric vehicles (EVs) have dominated the clean transportation conversation in recent years, hydrogen-powered vehicles are quietly making a comeback, thanks to a wave of technological innovations.

Hydrogen has long been seen as a potential game-changer in the automotive world. It’s abundant, energy-dense, and when used in a fuel cell, it produces electricity with only water as a byproduct. But for decades, challenges like high production costs, inefficient storage, and lack of infrastructure held hydrogen vehicles back. Today, those barriers are crumbling. Advances in fuel cell technology, green hydrogen production, and vehicle design are transforming hydrogen cars from niche prototypes into real contenders in the clean mobility race.

How Hydrogen Car Engines Work: A Simple Breakdown

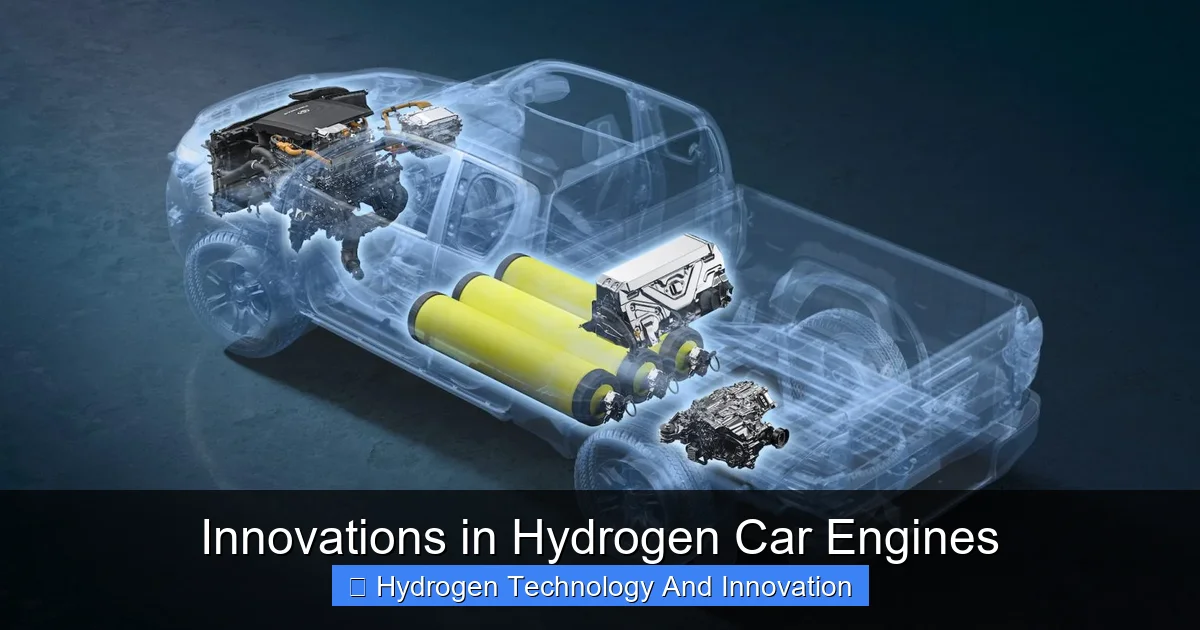

Visual guide about Innovations in Hydrogen Car Engines

Image source: mag.toyota.co.uk

Before diving into the latest innovations, it helps to understand how hydrogen car engines actually function. Unlike traditional gasoline engines that burn fuel, hydrogen vehicles typically use fuel cells to generate electricity. Here’s how it works in plain terms.

Inside a hydrogen fuel cell, hydrogen gas (H₂) is fed into the anode side of the cell. At the same time, oxygen from the air enters the cathode side. A special membrane called a proton exchange membrane (PEM) sits in the middle. This membrane allows positively charged hydrogen ions (protons) to pass through to the cathode, but blocks electrons. Those electrons are forced to travel through an external circuit, creating an electric current that powers the car’s motor.

At the cathode, the hydrogen ions, electrons, and oxygen combine to form water (H₂O)—the only emission. This process is silent, efficient, and produces no harmful pollutants. The electricity generated can either power the vehicle directly or charge a small battery that assists during acceleration.

Fuel Cells vs. Hydrogen Combustion Engines

It’s important to note that not all hydrogen engines are the same. There are two main types: fuel cell electric vehicles (FCEVs) and hydrogen internal combustion engines (HICEVs). FCEVs, like the Toyota Mirai or Hyundai NEXO, use fuel cells to generate electricity. They’re quiet, efficient, and produce zero emissions.

HICEVs, on the other hand, burn hydrogen in a modified gasoline engine. While they still emit only water and small amounts of nitrogen oxides (NOx), they’re less efficient than fuel cells and are mostly used in experimental or heavy-duty applications. Most innovations today focus on improving fuel cell technology, as it offers the cleanest and most efficient path forward.

Breakthroughs in Fuel Cell Technology

The heart of any hydrogen car is its fuel cell stack—the system that converts hydrogen into electricity. Recent innovations are making these stacks smaller, lighter, more durable, and cheaper to produce.

Improved Catalysts and Membranes

One of the biggest challenges in fuel cell design has been the use of expensive platinum-based catalysts. Platinum is rare and costly, driving up the price of fuel cells. But researchers are now developing alternative catalysts using non-precious metals like iron and cobalt, or even carbon-based materials. These new catalysts are not only cheaper but also more durable under real-world conditions.

At the same time, advancements in membrane technology are boosting efficiency. Newer PEMs can operate at higher temperatures and lower humidity, reducing the need for complex cooling and humidification systems. This simplifies the overall design and improves reliability.

Stack Design and Manufacturing Innovations

Fuel cell stacks are made up of hundreds of individual cells layered together. Innovations in stack design are allowing manufacturers to pack more power into smaller spaces. For example, Toyota has developed a new stack that’s 20% smaller and 30% lighter than previous versions, while delivering the same power output.

Automated manufacturing techniques are also reducing production costs. Companies like Ballard Power Systems are using roll-to-roll printing to produce fuel cell components at high speeds, similar to how newspapers are printed. This mass-production approach could bring down costs significantly, making hydrogen vehicles more competitive with EVs and gasoline cars.

Durability and Cold-Weather Performance

Early fuel cells struggled in cold climates, often failing to start in freezing temperatures. But new designs now include built-in heating elements and improved water management systems that prevent ice buildup. Hyundai’s latest NEXO, for instance, can start in temperatures as low as -30°C (-22°F), making it viable in colder regions like Canada and Scandinavia.

Durability has also improved. Modern fuel cells can now last over 10,000 hours of operation—equivalent to driving 300,000 miles—without significant degradation. This matches or exceeds the lifespan of traditional engines, addressing one of the major concerns about long-term reliability.

Advances in Hydrogen Storage Solutions

Storing hydrogen safely and efficiently has been a major hurdle. Hydrogen is the lightest element and highly flammable, so it must be stored under high pressure or at very low temperatures. Innovations in storage technology are making this process safer, lighter, and more practical.

High-Pressure Composite Tanks

Most hydrogen cars today use Type IV composite tanks, which are made of a plastic liner wrapped in carbon fiber. These tanks can withstand pressures of up to 700 bar (10,000 psi)—enough to store enough hydrogen for a range of 300–400 miles. New manufacturing techniques are reducing the weight and cost of these tanks, while improving their crash resistance.

For example, Hexagon Purus, a Norwegian company, has developed ultra-lightweight tanks that reduce vehicle weight by up to 50% compared to older steel tanks. This not only improves fuel efficiency but also allows for more passenger and cargo space.

Liquid Hydrogen and Cryogenic Storage

While most passenger vehicles use compressed gas, some heavy-duty trucks and experimental cars are exploring liquid hydrogen storage. Liquid hydrogen takes up less space and offers higher energy density, but it must be kept at -253°C (-423°F), requiring advanced insulation.

Companies like BMW and Toyota have tested liquid hydrogen prototypes, and while widespread adoption is still years away, the technology holds promise for long-haul transportation. New cryogenic materials and vacuum-insulated tanks are making liquid storage more feasible and safer.

Solid-State and Chemical Storage

Researchers are also exploring solid-state storage methods, where hydrogen is absorbed into materials like metal hydrides or carbon nanotubes. These systems could allow for safer, ambient-pressure storage, eliminating the need for high-pressure tanks.

For instance, the U.S. Department of Energy is funding projects on ammonia-based hydrogen storage, where hydrogen is extracted from ammonia on-demand inside the vehicle. This approach could simplify refueling and reduce infrastructure costs, though it’s still in the early stages.

Green Hydrogen: The Clean Fuel Revolution

Even the cleanest hydrogen car is only as green as the hydrogen it uses. Most hydrogen today is produced from natural gas through a process called steam methane reforming, which emits carbon dioxide. But the real breakthrough is green hydrogen—hydrogen produced using renewable energy.

Electrolysis Powered by Renewables

Green hydrogen is made by splitting water (H₂O) into hydrogen and oxygen using electricity from solar, wind, or hydro power. This process, called electrolysis, produces zero emissions when powered by renewables. Countries like Germany, Australia, and Chile are investing heavily in large-scale electrolyzer plants to produce green hydrogen for industrial and transportation use.

For example, the HyDeal Ambition project in Spain aims to produce green hydrogen at scale by 2030, using solar farms across the Iberian Peninsula. The goal is to make green hydrogen cheaper than fossil-based hydrogen, creating a sustainable fuel supply chain.

Onboard Hydrogen Production

Some innovators are exploring ways to produce hydrogen directly in the vehicle. For instance, a startup called H2Pro has developed a compact electrolyzer that could be installed in cars, allowing drivers to generate hydrogen from water using solar-charged batteries. While still experimental, this concept could revolutionize refueling by eliminating the need for hydrogen stations.

Hydrogen from Waste and Biomass

Another promising avenue is producing hydrogen from organic waste or biomass. Technologies like gasification and pyrolysis can convert agricultural residues, food waste, or even sewage into hydrogen. This not only provides a clean fuel source but also helps manage waste and reduce landfill emissions.

In Japan, a pilot project is converting food waste from Tokyo restaurants into hydrogen for fuel cell buses. This circular approach turns a pollution problem into a clean energy solution.

Infrastructure and Refueling Innovations

One of the biggest barriers to hydrogen car adoption has been the lack of refueling stations. But that’s changing fast, thanks to public and private investments in hydrogen infrastructure.

Expanding Hydrogen Station Networks

Countries like Japan, South Korea, Germany, and the U.S. (especially California) are leading the way in building hydrogen refueling networks. As of 2024, there are over 1,000 hydrogen stations worldwide, with hundreds more under construction.

In California, the state government has committed to building 200 stations by 2025, supported by automaker partnerships. Shell, Toyota, and Hyundai are jointly funding new stations, while companies like Air Liquide and Linde are expanding their industrial hydrogen networks to include public refueling.

Mobile and Modular Refueling Solutions

To serve rural or remote areas, companies are developing mobile hydrogen refuelers—trucks equipped with compressors and storage tanks that can deliver hydrogen on demand. These mobile units can support emergency services, construction sites, or temporary events.

Modular stations are also gaining traction. These prefabricated units can be installed quickly and scaled up as demand grows. They’re ideal for fleet operators, such as delivery companies or public transit agencies, who want to transition to hydrogen without waiting for permanent infrastructure.

Home Refueling and Personal Stations

Imagine refueling your hydrogen car at home, just like charging an EV. Companies like Atmosfy and H2GOPOWER are developing compact home refueling systems that use electrolysis to produce hydrogen from tap water and solar power.

These systems are still expensive and limited in output, but they represent a future where hydrogen refueling is as convenient as plugging in. As technology improves and costs fall, home hydrogen stations could become as common as EV chargers.

Automaker Commitment and Real-World Applications

Automakers are not just talking about hydrogen—they’re investing billions in real vehicles and fleets. While passenger cars are the most visible, hydrogen is proving especially valuable in heavy-duty transportation.

Passenger Vehicles: Mirai, NEXO, and Beyond

Toyota’s Mirai and Hyundai’s NEXO are the most well-known hydrogen cars on the market. The second-generation Mirai, launched in 2021, offers over 400 miles of range and a sleek, modern design. Hyundai’s NEXO boasts similar range and advanced driver-assistance features.

Other automakers are entering the space. BMW plans to launch a hydrogen version of its X5 SUV by 2025, using a fuel cell system developed with Toyota. Even luxury brands like Audi and Mercedes-Benz are exploring hydrogen concepts for high-end models.

Hydrogen Trucks and Buses

Heavy-duty vehicles are a natural fit for hydrogen. Trucks and buses travel long distances and need quick refueling—something hydrogen can deliver in minutes, unlike battery-electric vehicles that require hours to charge.

Companies like Nikola, Hyzon, and Daimler are producing hydrogen-powered trucks for freight and logistics. In Europe, cities like London and Berlin are adding hydrogen buses to their public transit fleets. These vehicles reduce urban air pollution and noise, improving quality of life.

Aviation and Maritime Applications

Hydrogen isn’t just for roads. Airbus is developing hydrogen-powered aircraft, aiming for zero-emission flights by 2035. The ZEROe program includes concepts for turboprop, jet, and blended-wing designs that use liquid hydrogen.

Similarly, shipping companies are testing hydrogen and ammonia-powered vessels. The world’s first hydrogen-fueled ferry, the MF Hydra, began operating in Norway in 2023. These early adopters are paving the way for a cleaner global transport system.

The Road Ahead: Challenges and Opportunities

Despite the progress, hydrogen car engines still face challenges. Costs remain high, infrastructure is uneven, and public awareness is low. But the momentum is building.

Cost Reduction Through Scale

As production scales up, costs will fall. The U.S. Department of Energy estimates that fuel cell costs could drop by 80% by 2030 with mass production and innovation. Similarly, green hydrogen prices are expected to fall below $2 per kilogram—making it competitive with gasoline on a cost-per-mile basis.

Policy Support and Incentives

Governments are stepping in to help. The U.S. Inflation Reduction Act includes tax credits for hydrogen production and fuel cell vehicles. The European Union’s Green Deal funds hydrogen infrastructure and research. Japan’s Basic Hydrogen Strategy aims to make the country a hydrogen society by 2050.

These policies are creating a stable environment for investment and innovation, accelerating the transition.

Public Education and Consumer Adoption

One of the biggest hurdles is public perception. Many people still don’t know how hydrogen cars work or believe they’re unsafe. Automakers and governments need to invest in education campaigns, test drives, and transparent safety data.

As more people experience the quiet, smooth ride of a hydrogen car—and see water dripping from the tailpipe—attitudes will shift.

Conclusion: A Hydrogen-Powered Future Is Closer Than You Think

The innovations in hydrogen car engines are not just incremental—they’re transformative. From more efficient fuel cells and safer storage to green hydrogen production and expanding infrastructure, the pieces of the puzzle are falling into place. While challenges remain, the progress is undeniable.

Hydrogen won’t replace all vehicles overnight, but it will play a vital role in a diversified clean transportation future. For long-haul trucks, buses, and regions with limited EV charging, hydrogen offers a practical, zero-emission solution. And as technology improves and costs decline, hydrogen cars could become a common sight on roads around the world.

The future of mobility isn’t just electric—it’s electric, hydrogen, and everything in between. And with each innovation, we move one step closer to a cleaner, quieter, and more sustainable world.

Frequently Asked Questions

How does a hydrogen car engine work?

A hydrogen car engine typically uses a fuel cell to convert hydrogen gas and oxygen into electricity, which powers the vehicle. The only byproduct is water vapor, making it a zero-emission technology.

Are hydrogen cars safe?

Yes, hydrogen cars are designed with multiple safety features, including leak detection, automatic shutoff valves, and reinforced storage tanks. They undergo rigorous testing and meet strict safety standards.

How far can a hydrogen car go on a full tank?

Most modern hydrogen cars, like the Toyota Mirai or Hyundai NEXO, offer a range of 300–400 miles on a single fill-up, comparable to gasoline vehicles.

How long does it take to refuel a hydrogen car?

Refueling a hydrogen car takes about 3–5 minutes, similar to filling up a gasoline vehicle—much faster than charging most electric cars.

Is hydrogen fuel expensive?

Currently, hydrogen fuel is more expensive than gasoline or electricity, but costs are expected to drop as production scales up and green hydrogen becomes more widespread.

Where can I refuel a hydrogen car?

Hydrogen refueling stations are available in select regions, including California, Japan, South Korea, and parts of Europe. Networks are expanding rapidly with government and industry support.