Hydrogen-powered vehicles are gaining momentum as a clean alternative to fossil fuels, but storing hydrogen safely and efficiently remains a key challenge. Recent breakthroughs in materials science, tank design, and system integration are transforming how hydrogen is stored, making fuel cell vehicles more practical, affordable, and accessible.

Key Takeaways

- Hydrogen storage is critical for fuel cell vehicle performance and safety: Efficient storage enables longer driving ranges and faster refueling, matching or exceeding conventional vehicles.

- High-pressure gaseous storage dominates current technology: Most hydrogen vehicles use 700-bar compressed gas tanks, but research is pushing toward lighter, stronger materials.

- Solid-state and liquid storage methods are emerging as game-changers: Metal hydrides, chemical hydrides, and cryogenic liquids offer higher energy density and improved safety.

- Advanced materials like carbon nanotubes and MOFs show promise: These nanomaterials can absorb and release hydrogen efficiently at lower pressures and temperatures.

- Hybrid and modular storage systems are being developed: Combining multiple storage methods can optimize performance, weight, and cost for different vehicle types.

- Safety and cost remain top priorities: Innovations focus on leak prevention, thermal management, and scalable manufacturing to make hydrogen storage viable for mass adoption.

- Government and industry collaboration is accelerating progress: Partnerships between automakers, research labs, and energy companies are driving real-world testing and commercialization.

📑 Table of Contents

- Introduction: The Hydrogen Revolution on the Road

- Why Hydrogen Storage Matters for the Future of Transportation

- Current State of Hydrogen Storage: Compressed Gas Tanks

- Emerging Technologies: Solid-State and Liquid Hydrogen Storage

- Hybrid and Modular Storage Systems

- Overcoming Challenges: Cost, Safety, and Scalability

- The Road Ahead: What’s Next for Hydrogen Storage?

- Conclusion

Introduction: The Hydrogen Revolution on the Road

Imagine a car that emits nothing but water vapor, refuels in under five minutes, and travels over 500 miles on a single tank. That’s not science fiction—it’s the promise of hydrogen fuel cell vehicles (FCVs). As the world races toward decarbonization, hydrogen is emerging as a powerful player in the clean transportation revolution. But for all its potential, hydrogen has a stubborn problem: how do you store it safely, efficiently, and affordably in a vehicle?

Unlike gasoline or batteries, hydrogen is the lightest and most diffusive element on the periodic table. It takes up a lot of space, even when compressed, and it can weaken metals over time—a phenomenon known as hydrogen embrittlement. These challenges have made storage one of the biggest hurdles in making hydrogen-powered cars mainstream. Yet, thanks to rapid advancements in materials science, engineering, and system design, we’re now witnessing a wave of innovations that are turning the tide.

From high-tech carbon fiber tanks to futuristic metal-organic frameworks, researchers and engineers are reimagining how hydrogen can be carried on board a vehicle. These breakthroughs aren’t just academic—they’re being tested in real-world prototypes and even commercial fleets. As governments set ambitious climate goals and automakers invest billions in hydrogen infrastructure, the race to perfect hydrogen storage has never been more urgent—or more promising.

Why Hydrogen Storage Matters for the Future of Transportation

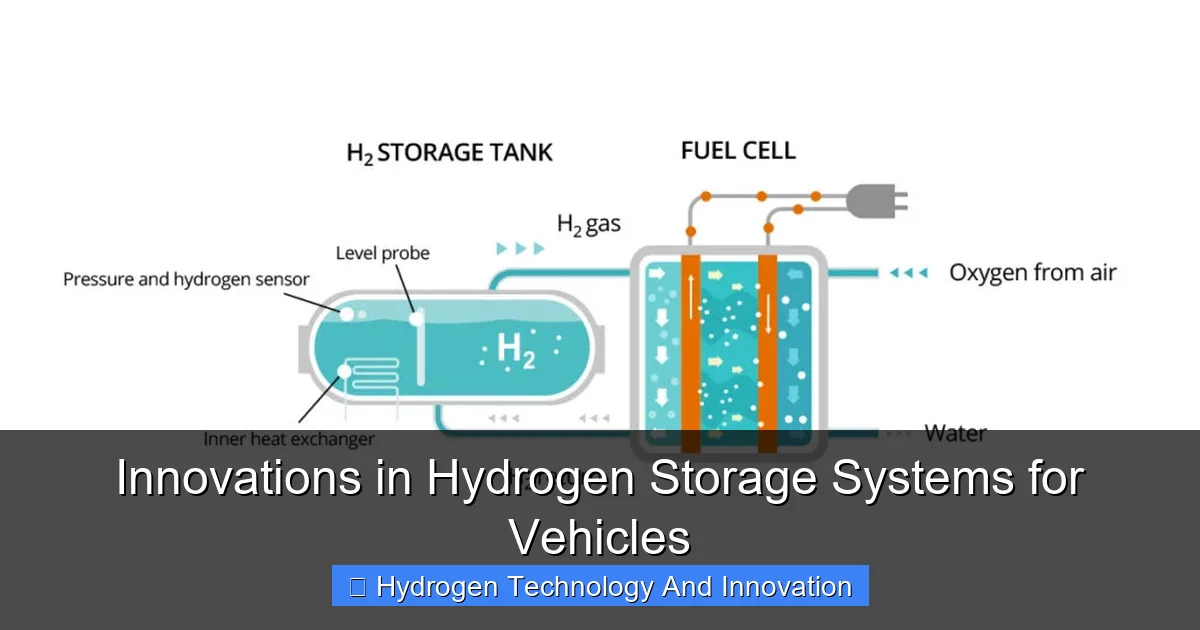

Visual guide about Innovations in Hydrogen Storage Systems for Vehicles

Image source: modelon.com

To understand why hydrogen storage is such a big deal, let’s start with the basics. Hydrogen is an incredibly clean fuel. When used in a fuel cell, it combines with oxygen from the air to produce electricity, with only water and heat as byproducts. No carbon dioxide, no smog-forming pollutants—just pure, clean energy. That makes it ideal for decarbonizing sectors where batteries struggle, like long-haul trucking, shipping, and aviation.

But here’s the catch: hydrogen has one of the lowest energy densities by volume of any fuel. At standard temperature and pressure, a kilogram of hydrogen takes up about 11,000 liters. That’s why you can’t just pour it into a regular gas tank. To make it practical for vehicles, hydrogen must be stored in a way that maximizes energy density while minimizing weight, volume, and safety risks.

There are three main ways to store hydrogen: as a compressed gas, as a cryogenic liquid, or in a solid or chemical form. Each method has trade-offs in terms of cost, efficiency, and safety. For example, compressing hydrogen to 700 times atmospheric pressure allows it to fit into a compact tank, but it requires strong, heavy containers and energy-intensive compression. Liquefying hydrogen makes it even denser, but it must be kept at -253°C (-423°F), which demands complex and energy-hungry cooling systems.

Despite these challenges, the benefits are too great to ignore. A well-designed hydrogen storage system can give a vehicle a range comparable to gasoline-powered cars, with refueling times of just a few minutes. That’s a huge advantage over battery electric vehicles (BEVs), which can take hours to recharge. And because hydrogen can be produced from renewable sources like wind and solar, it offers a truly sustainable path to zero-emission transportation.

The Role of Hydrogen in a Clean Energy Ecosystem

Hydrogen isn’t just about cars. It’s part of a broader vision for a clean energy future. Known as the “hydrogen economy,” this concept involves producing, distributing, and using hydrogen across multiple sectors—transportation, industry, and power generation. In this ecosystem, excess renewable energy can be used to split water into hydrogen and oxygen through electrolysis. The hydrogen is then stored and used when needed, acting as a clean energy carrier.

For transportation, this means hydrogen can complement batteries rather than compete with them. While BEVs are ideal for short-range urban driving, hydrogen FCVs shine in applications requiring long range, heavy payloads, or fast refueling. Think delivery trucks, buses, trains, and even ships. In fact, companies like Toyota, Hyundai, and Nikola are already testing hydrogen-powered trucks for freight transport.

But none of this is possible without reliable, efficient hydrogen storage. The success of the hydrogen economy hinges on our ability to store hydrogen safely and cost-effectively. That’s why researchers, engineers, and policymakers are pouring resources into developing next-generation storage technologies. The innovations happening today aren’t just improving vehicles—they’re laying the foundation for a cleaner, more resilient energy system.

Current State of Hydrogen Storage: Compressed Gas Tanks

Today, the most common method for storing hydrogen in vehicles is high-pressure compressed gas. Most fuel cell vehicles on the road—like the Toyota Mirai, Hyundai NEXO, and Honda Clarity—use tanks pressurized to 700 bar (about 10,000 psi). That’s roughly 2.5 times the pressure of a typical scuba tank.

These tanks are made from advanced composite materials, typically a carbon fiber shell wrapped around a lightweight aluminum or polymer liner. The carbon fiber provides incredible strength while keeping the tank light—a critical factor for vehicle efficiency. Modern 700-bar tanks can store about 5–6 kilograms of hydrogen, enough to give a car a range of 300–400 miles.

One of the biggest advantages of compressed gas storage is simplicity. The technology is mature, well-understood, and compatible with existing refueling infrastructure. Hydrogen stations can compress and dispense gas quickly, allowing drivers to refuel in under five minutes—just like gasoline. That’s a major selling point for consumers and fleet operators who value convenience.

But compressed gas isn’t without its drawbacks. The tanks are still relatively heavy and expensive. Carbon fiber is strong but costly to produce, and the manufacturing process is energy-intensive. There are also safety concerns. While modern tanks are designed to withstand crashes, fires, and punctures, the high pressure means any failure could be dangerous. That’s why strict safety standards and rigorous testing are essential.

Improving Tank Design and Materials

To address these challenges, researchers are working on lighter, stronger, and cheaper tank materials. One promising approach is using hybrid composites that combine carbon fiber with other fibers like glass or basalt. These materials can reduce cost while maintaining performance.

Another innovation is the development of fully composite tanks without metal liners. Traditional tanks use aluminum or polymer liners to prevent hydrogen leakage, but these can degrade over time. Linerless tanks made entirely from advanced polymers or composites could be more durable and lighter, though they’re still in the experimental phase.

Thermal management is another area of focus. Compressing hydrogen generates heat, and if the gas isn’t cooled properly during refueling, it can overheat the tank. Overheating can weaken the materials and reduce storage capacity. New cooling systems and smart refueling protocols are being developed to manage temperature more effectively.

Safety and Regulatory Standards

Safety is paramount in hydrogen storage. Because hydrogen is odorless, colorless, and highly flammable, leaks can be hard to detect. That’s why modern tanks are equipped with multiple safety features, including pressure relief devices, hydrogen sensors, and automatic shut-off valves.

Regulatory bodies like the U.S. Department of Transportation (DOT) and the United Nations Economic Commission for Europe (UNECE) have established strict standards for hydrogen tanks. These include tests for burst pressure, fatigue resistance, and fire exposure. Tanks must survive being shot with bullets, exposed to flames, and dropped from heights without failing.

Automakers also conduct extensive real-world testing. For example, Toyota’s Mirai tanks have undergone over 10,000 hours of testing, including crash simulations and extreme weather conditions. These efforts have helped build public confidence in hydrogen vehicle safety.

Emerging Technologies: Solid-State and Liquid Hydrogen Storage

While compressed gas is the current standard, researchers are exploring alternative storage methods that could offer higher density, better safety, and lower costs. Two of the most promising approaches are solid-state storage and cryogenic liquid storage.

Solid-State Hydrogen Storage

Solid-state storage involves binding hydrogen to a solid material, either physically (adsorption) or chemically (absorption). This allows hydrogen to be stored at lower pressures and temperatures, reducing the risk of leaks and explosions.

One of the most studied materials for solid-state storage is metal hydrides. These are compounds like sodium alanate or magnesium hydride that absorb hydrogen into their crystal structure. When heated, they release the hydrogen on demand. The advantage is high volumetric density—some metal hydrides can store more hydrogen per liter than liquid hydrogen.

However, metal hydrides have drawbacks. They are often heavy, which reduces the overall energy efficiency of the vehicle. They also require heat to release hydrogen, which can slow down refueling and reduce responsiveness. And many hydrides degrade over time, losing their capacity after repeated cycles.

Another promising material is chemical hydrides, such as ammonia borane. These compounds release hydrogen through chemical reactions, often triggered by catalysts. They offer high hydrogen content and can be stored at room temperature. But they produce waste byproducts that must be managed, and the regeneration process is complex and energy-intensive.

Nanomaterials: Carbon Nanotubes and Metal-Organic Frameworks

Nanotechnology is opening new frontiers in hydrogen storage. Carbon nanotubes (CNTs) and metal-organic frameworks (MOFs) are ultra-porous materials with enormous surface areas—sometimes over 3,000 square meters per gram. This allows them to adsorb large amounts of hydrogen at relatively low pressures.

MOFs, in particular, are like molecular sponges. They consist of metal ions connected by organic linkers, forming a lattice with tiny pores. By tuning the size and chemistry of these pores, scientists can optimize them for hydrogen uptake. Some MOFs have demonstrated hydrogen storage capacities close to the U.S. Department of Energy’s targets.

The challenge is making these materials practical. CNTs and MOFs are still expensive to produce at scale, and their hydrogen release kinetics need improvement. But ongoing research is focused on scaling up synthesis, reducing costs, and integrating these materials into real-world storage systems.

Cryogenic Liquid Hydrogen Storage

Liquid hydrogen (LH2) is another option. At -253°C, hydrogen becomes a liquid, reducing its volume by a factor of 800 compared to gas at room temperature. This allows for much higher energy density, making it ideal for long-range applications like aviation and heavy-duty transport.

NASA has used liquid hydrogen for decades in rocket propulsion, proving its viability. But for vehicles, the challenges are significant. Maintaining cryogenic temperatures requires sophisticated insulation and refrigeration systems. Even the best insulation allows some heat to leak in, causing the liquid to “boil off” over time. This means liquid hydrogen tanks must be vented periodically, leading to fuel loss.

New vacuum-insulated tanks and advanced cryocoolers are helping reduce boil-off. Companies like Linde and Air Liquide are developing compact, efficient LH2 storage systems for vehicles. Toyota has also experimented with liquid hydrogen in racing prototypes, showing its potential for high-performance applications.

Hybrid and Modular Storage Systems

Rather than relying on a single storage method, some researchers are exploring hybrid systems that combine multiple technologies. For example, a vehicle might use a high-pressure tank for daily driving and a solid-state reservoir for extended range. Or it could switch between compressed gas and liquid hydrogen depending on the mission.

Modular storage is another emerging trend. Instead of one large tank, vehicles could use multiple smaller tanks distributed throughout the chassis. This improves weight distribution, frees up space, and enhances safety by isolating potential failures.

These systems are still in early development, but they represent a flexible, scalable approach to hydrogen storage. By tailoring the storage solution to the vehicle’s needs—whether it’s a city bus, a delivery van, or a long-haul truck—manufacturers can optimize performance, cost, and safety.

Case Study: The Hyundai XCIENT Fuel Cell Truck

A real-world example of advanced hydrogen storage in action is the Hyundai XCIENT Fuel Cell truck. Deployed in Switzerland and other countries, these heavy-duty trucks use two 90 kW fuel cell stacks and seven high-pressure hydrogen tanks. The tanks are mounted on the chassis and can store up to 31 kg of hydrogen, giving the truck a range of over 400 kilometers (250 miles).

Hyundai has focused on making the system robust and reliable. The tanks are designed for easy maintenance and can be refueled in under 10 minutes. The company is also working on a next-generation version with improved efficiency and reduced costs.

Overcoming Challenges: Cost, Safety, and Scalability

Despite the progress, hydrogen storage still faces significant hurdles. Cost is a major barrier. High-pressure tanks made from carbon fiber can cost thousands of dollars each, making hydrogen vehicles more expensive than their gasoline or battery-powered counterparts.

Safety remains a public concern. While hydrogen is no more dangerous than gasoline when handled properly, its invisible, odorless nature requires careful management. Education and transparent communication are key to building trust.

Scalability is another issue. Producing advanced materials like carbon fiber and MOFs at the scale needed for mass-market vehicles is a logistical challenge. Manufacturing processes must become faster, cheaper, and more sustainable.

Government and Industry Collaboration

To accelerate progress, governments and private companies are working together. In the U.S., the Department of Energy’s Hydrogen and Fuel Cell Technologies Office funds research into advanced storage materials and systems. The European Union’s Clean Hydrogen Partnership supports similar initiatives.

Automakers are also investing heavily. Toyota, Hyundai, and BMW have all announced plans to expand their hydrogen vehicle lineups. Energy companies like Shell and TotalEnergies are building hydrogen refueling networks across Europe and North America.

These collaborations are essential. No single company or country can solve the hydrogen storage challenge alone. By sharing knowledge, resources, and infrastructure, the industry can move faster toward a hydrogen-powered future.

The Road Ahead: What’s Next for Hydrogen Storage?

The future of hydrogen storage is bright. As materials science advances and manufacturing scales up, we can expect lighter, cheaper, and more efficient systems. Innovations like self-healing tanks, smart sensors, and AI-driven thermal management will further enhance safety and performance.

One exciting possibility is on-board hydrogen generation. Instead of storing pure hydrogen, future vehicles might carry chemical fuels like methanol or ammonia, which can be reformed into hydrogen as needed. This could simplify storage and leverage existing fuel infrastructure.

Another trend is the integration of hydrogen storage with renewable energy systems. Home hydrogen refueling stations, powered by solar panels, could allow consumers to produce and store their own fuel. This decentralized model could reduce reliance on large-scale infrastructure.

Ultimately, the goal is to make hydrogen storage as simple, safe, and affordable as filling up a gas tank. With continued innovation and collaboration, that vision is within reach.

Conclusion

Hydrogen storage is no longer a roadblock—it’s a frontier. From high-pressure tanks to nanomaterials and cryogenic liquids, the innovations happening today are transforming how we think about clean transportation. While challenges remain, the progress is undeniable. As technology improves and costs come down, hydrogen-powered vehicles will become a common sight on our roads. The journey to a zero-emission future is long, but with every breakthrough in hydrogen storage, we’re one step closer to reaching the destination.

Frequently Asked Questions

What is the most common method of hydrogen storage in vehicles today?

The most common method is high-pressure compressed gas storage, typically at 700 bar. This approach uses lightweight composite tanks made from carbon fiber and is used in vehicles like the Toyota Mirai and Hyundai NEXO.

Are hydrogen storage tanks safe?

Yes, modern hydrogen tanks are designed to be extremely safe. They undergo rigorous testing for crash resistance, fire exposure, and pressure integrity. Safety features like pressure relief devices and hydrogen sensors further reduce risks.

How does solid-state hydrogen storage work?

Solid-state storage binds hydrogen to materials like metal hydrides or metal-organic frameworks (MOFs). These materials absorb hydrogen at low pressures and release it when heated, offering higher density and improved safety compared to compressed gas.

Can hydrogen be stored as a liquid in vehicles?

Yes, liquid hydrogen is used in some applications, especially in aviation and heavy transport. It offers high energy density but requires cryogenic temperatures (-253°C) and advanced insulation to prevent boil-off.

What are the main challenges in hydrogen storage?

The main challenges include high cost, weight, safety concerns, and energy losses during compression or liquefaction. Researchers are working to develop lighter, cheaper, and more efficient storage solutions.

Will hydrogen vehicles ever be as common as electric cars?

Hydrogen vehicles are likely to complement, rather than replace, battery electric vehicles. They excel in long-range and heavy-duty applications, and as storage technology improves, they could become more widespread in specific sectors.