Renewable hydrogen production is revolutionizing the clean energy landscape by offering a zero-emission fuel source made from water and renewable electricity. This green fuel is essential for decarbonizing hard-to-abate sectors like heavy industry and long-haul transport.

Key Takeaways

- Renewable hydrogen is produced using clean energy sources like wind and solar: Unlike gray hydrogen, it emits no carbon dioxide during production, making it a truly sustainable fuel.

- It plays a critical role in achieving global climate goals: By replacing fossil fuels in industries such as steel, cement, and shipping, renewable hydrogen helps reduce greenhouse gas emissions.

- Electrolysis is the primary method for green hydrogen production: This process splits water into hydrogen and oxygen using electricity from renewable sources.

- Energy storage and grid balancing are key benefits: Excess renewable energy can be stored as hydrogen, providing stability to power grids and enabling long-term energy storage.

- Transportation and heavy industry are major application areas: Hydrogen fuel cells power trucks, ships, and trains, while hydrogen replaces coal in steelmaking.

- Government policies and investments are accelerating adoption: Countries like Germany, Japan, and Australia are leading the way with national hydrogen strategies and funding.

- Challenges remain, including cost and infrastructure: Lowering production costs and building hydrogen refueling networks are essential for widespread use.

Key Takeaways

- Understanding Renewable hydrogen production and its importance: Provides essential knowledge

📑 Table of Contents

- Introduction: The Rise of Renewable Hydrogen

- What Is Renewable Hydrogen and How Is It Made?

- Why Renewable Hydrogen Matters for Climate Goals

- Applications of Renewable Hydrogen Across Industries

- Global Progress and Government Support

- Challenges and the Path Forward

- Conclusion: A Cleaner Future with Renewable Hydrogen

Introduction: The Rise of Renewable Hydrogen

Imagine a world where heavy trucks, cargo ships, and steel factories run without polluting the air. That future is closer than you think—thanks to renewable hydrogen production. This clean fuel, made using electricity from wind, solar, and hydropower, is emerging as a game-changer in the fight against climate change. Unlike traditional hydrogen, which is often produced from natural gas and releases carbon dioxide, renewable hydrogen is made without emissions. It’s called “green hydrogen” for a reason—it’s clean, sustainable, and key to a zero-carbon future.

The energy transition isn’t just about replacing coal with solar panels or gas with wind turbines. It’s also about finding solutions for sectors that are hard to electrify directly. Think about steel mills that need intense heat, or cargo ships that travel thousands of miles without refueling. Batteries alone can’t handle these demands. That’s where renewable hydrogen steps in. It can store energy, power industrial processes, and fuel long-distance transport—all while producing only water as a byproduct.

What Is Renewable Hydrogen and How Is It Made?

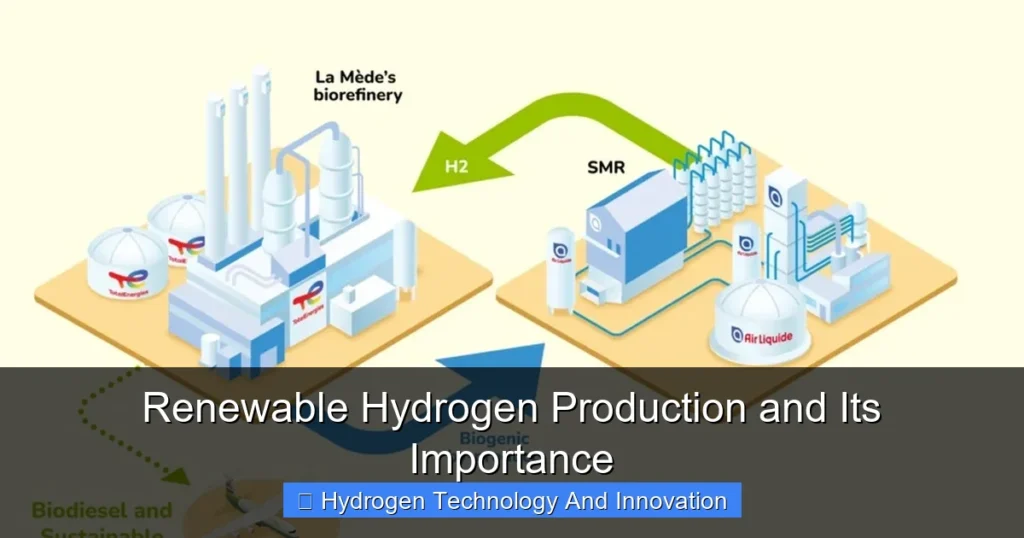

Visual guide about Renewable Hydrogen Production and Its Importance

Image source: img.fuelcellsworks.com

Renewable hydrogen, often referred to as green hydrogen, is hydrogen gas produced using renewable energy sources and water. The most common method is called electrolysis, a process that uses electricity to split water (H₂O) into hydrogen (H₂) and oxygen (O₂). When that electricity comes from wind, solar, or hydropower, the entire process is carbon-free.

Understanding Electrolysis: The Heart of Green Hydrogen

Electrolysis happens in a device called an electrolyzer. Inside, water flows over electrodes connected to a power source. When electricity passes through, it breaks the water molecules apart. Hydrogen gas bubbles up at the cathode (negative electrode), while oxygen is released at the anode (positive electrode). The hydrogen is then collected, purified, and stored for use.

There are different types of electrolyzers, each suited for various applications:

- Proton Exchange Membrane (PEM) Electrolyzers: These are compact and respond quickly to changes in power supply, making them ideal for pairing with solar or wind farms.

- Alkaline Electrolyzers: A more established technology, these are cost-effective and widely used in industrial settings.

- Solid Oxide Electrolyzers (SOEC): These operate at high temperatures and are highly efficient, especially when paired with waste heat from industrial processes.

The key to making hydrogen truly renewable is ensuring the electricity used comes from clean sources. If the grid is powered by coal or gas, the hydrogen produced isn’t green—even if the process looks the same. That’s why renewable hydrogen production depends on expanding wind and solar capacity.

Other Methods: Beyond Electrolysis

While electrolysis is the leading method, researchers are exploring other ways to produce renewable hydrogen. One promising approach is thermochemical water splitting, which uses high-temperature heat from concentrated solar power to break down water. Another is biological hydrogen production, where certain bacteria or algae produce hydrogen under specific conditions.

However, these methods are still in early development. Electrolysis remains the most scalable and commercially viable path forward. Companies like Siemens Energy, ITM Power, and Nel Hydrogen are already deploying large-scale electrolyzers around the world.

Why Renewable Hydrogen Matters for Climate Goals

The world is racing to cut greenhouse gas emissions and limit global warming to 1.5°C above pre-industrial levels. According to the International Energy Agency (IEA), hydrogen could account for 13% of global final energy demand by 2050 in a net-zero scenario. Renewable hydrogen is central to this vision.

Decarbonizing Hard-to-Abate Sectors

Some industries are notoriously difficult to decarbonize. Heavy transport, aviation, shipping, and industrial processes like steel and cement production require high energy density and intense heat—conditions that are hard to meet with batteries or direct electrification.

Take steelmaking, for example. Traditionally, coal is used to reduce iron ore into iron, releasing large amounts of CO₂. But companies like SSAB in Sweden are now using hydrogen instead. In their HYBRIT project, hydrogen reacts with iron ore to produce sponge iron and water—no carbon emissions. This breakthrough could eliminate up to 10% of Sweden’s total CO₂ emissions.

Similarly, in shipping, companies like Maersk are investing in green ammonia (made from renewable hydrogen) to power cargo ships. Ammonia can be used as a fuel or converted back to hydrogen on board. This allows long voyages without refueling and without burning fossil fuels.

Supporting Renewable Energy Integration

One of the biggest challenges with wind and solar power is their variability. The sun doesn’t always shine, and the wind doesn’t always blow. This creates mismatches between energy supply and demand.

Renewable hydrogen offers a solution. Excess electricity from solar panels or wind turbines can be used to produce hydrogen through electrolysis. This hydrogen can then be stored for weeks or months and used later—either to generate electricity in fuel cells or as a feedstock for industry.

For example, in South Australia, the government is building a hydrogen energy storage system to store surplus wind energy. During periods of low demand, excess power runs electrolyzers. When demand spikes, the stored hydrogen powers turbines to feed electricity back into the grid. This helps stabilize the grid and reduces reliance on fossil fuel backups.

Applications of Renewable Hydrogen Across Industries

Renewable hydrogen isn’t just a lab experiment—it’s already being used in real-world applications across multiple sectors. Its versatility makes it a valuable tool in the clean energy toolkit.

Transportation: Fueling the Future

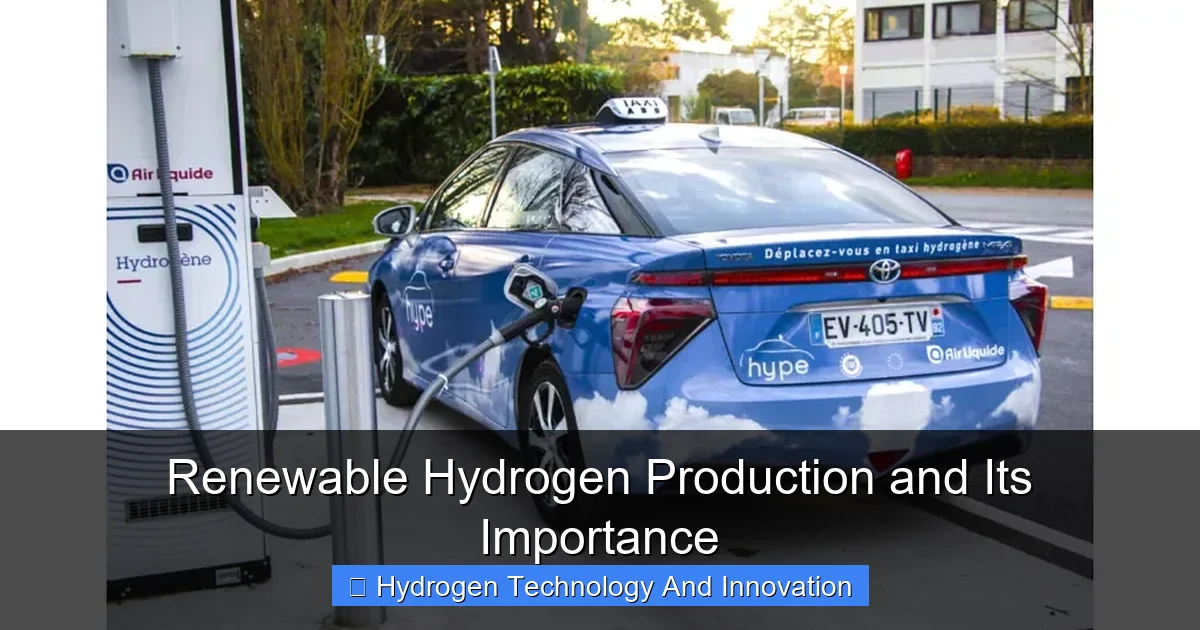

Hydrogen fuel cell vehicles (FCEVs) are gaining traction, especially in heavy-duty transport. Unlike battery-electric trucks, which can take hours to recharge, hydrogen trucks can refuel in minutes and travel long distances.

In California, the Port of Los Angeles is testing hydrogen-powered drayage trucks to move containers from ships to warehouses. These trucks produce zero emissions and reduce air pollution in nearby communities. Similarly, in Germany, hydrogen trains are replacing diesel locomotives on non-electrified rail lines. The Coradia iLint, built by Alstom, runs on hydrogen and emits only water vapor.

Aviation is also exploring hydrogen. Airbus aims to launch a hydrogen-powered commercial aircraft by 2035. While challenges remain—like storing hydrogen at low temperatures—early prototypes show promise for short- to medium-haul flights.

Industry: Replacing Fossil Fuels

Industrial processes account for nearly 25% of global CO₂ emissions. Renewable hydrogen can replace fossil fuels in many of these applications.

In chemicals manufacturing, hydrogen is a key ingredient for producing ammonia, methanol, and other compounds. Traditionally, this hydrogen comes from natural gas (gray hydrogen). Switching to green hydrogen cuts emissions significantly.

In refining, hydrogen is used to remove sulfur from crude oil. Using renewable hydrogen makes the entire refining process cleaner.

And in glass and ceramics production, hydrogen can serve as a clean fuel for high-temperature furnaces. Pilots in the UK and the Netherlands are testing hydrogen-fired kilns with promising results.

Power Generation and Grid Stability

Hydrogen can also play a role in electricity generation. Gas turbines can be modified to burn hydrogen instead of natural gas. In the UK, the Keadby 2 power plant will run on a blend of hydrogen and natural gas, with plans to go 100% hydrogen in the future.

Fuel cells offer another path. These devices convert hydrogen directly into electricity with high efficiency and no emissions. They’re being used in backup power systems, remote microgrids, and even data centers.

Moreover, hydrogen supports grid flexibility. During times of low electricity demand, excess renewable power can be stored as hydrogen. When demand rises, that hydrogen can be converted back to electricity. This helps balance the grid and reduces curtailment of wind and solar farms.

Global Progress and Government Support

Countries around the world are recognizing the potential of renewable hydrogen and investing heavily in its development.

National Hydrogen Strategies

Germany launched its National Hydrogen Strategy in 2020, committing €9 billion to build a green hydrogen economy. The country aims to become a global leader in hydrogen technology and import green hydrogen from North Africa and the Middle East.

Japan has been a pioneer in hydrogen adoption for years. Its “Basic Hydrogen Strategy” targets hydrogen as a core energy source by 2050. The country is investing in hydrogen refueling stations, fuel cell vehicles, and international supply chains.

Australia is leveraging its vast renewable resources to become a major hydrogen exporter. Projects like the Asian Renewable Energy Hub in Western Australia plan to produce green hydrogen and ammonia for export to Asia.

The United States has also stepped up. The Inflation Reduction Act (2022) includes tax credits of up to $3 per kilogram for clean hydrogen production, making green hydrogen cost-competitive with fossil-based alternatives.

International Collaboration

No country can go it alone. International partnerships are essential for scaling up renewable hydrogen production and trade.

The European Union is developing a hydrogen backbone—a network of pipelines to transport hydrogen across member states. It’s also working on certification schemes to ensure hydrogen is truly green.

The Hydrogen Council, a global CEO-led initiative, brings together over 100 companies to accelerate hydrogen deployment. Members include Toyota, Shell, and Air Liquide.

And the International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) promotes collaboration on standards, safety, and research.

Challenges and the Path Forward

Despite its promise, renewable hydrogen faces several hurdles. Overcoming them will require innovation, investment, and policy support.

High Production Costs

Currently, green hydrogen costs between $3 and $6 per kilogram, compared to $1–$2 for gray hydrogen. The main cost drivers are electrolyzers and renewable electricity.

But costs are falling. The U.S. Department of Energy’s “Hydrogen Shot” aims to reduce the cost of clean hydrogen to $1 per kilogram within a decade. Advances in electrolyzer efficiency, economies of scale, and cheaper renewables will help achieve this.

Infrastructure Gaps

Hydrogen requires specialized infrastructure for storage, transport, and distribution. Unlike natural gas, it’s less dense and can embrittle metals. New pipelines, compression systems, and refueling stations are needed.

Blending hydrogen into existing natural gas pipelines is a short-term solution. Some countries are already testing blends of up to 20% hydrogen in gas networks.

For long-distance transport, hydrogen is often converted into ammonia or liquid organic carriers (LOHCs) for easier shipping.

Energy Efficiency Concerns

Producing hydrogen via electrolysis is less efficient than using electricity directly. It takes about 50–60 kWh of electricity to produce 1 kg of hydrogen, which can then generate around 33 kWh of electricity in a fuel cell. That’s an overall efficiency of 55–65%.

This means hydrogen is best used where direct electrification isn’t feasible—like in heavy industry or long-haul transport. For passenger cars or home heating, batteries or heat pumps are often more efficient.

Policy and Regulation

Clear policies are needed to create market certainty. Governments must set standards for what counts as “green” hydrogen, provide financial incentives, and support research and development.

Carbon pricing can also level the economic playing field. By putting a price on CO₂ emissions, gray hydrogen becomes more expensive, making green hydrogen more competitive.

Conclusion: A Cleaner Future with Renewable Hydrogen

Renewable hydrogen production is more than a technological breakthrough—it’s a cornerstone of a sustainable energy future. By harnessing wind, solar, and water, we can create a clean fuel that powers industries, transports goods, and stores energy—all without emitting carbon dioxide.

While challenges remain, the momentum is undeniable. From pilot projects in Sweden to national strategies in Japan and Germany, the world is waking up to hydrogen’s potential. With continued innovation, investment, and international cooperation, renewable hydrogen can help us meet climate goals, enhance energy security, and build a cleaner, healthier planet.

The journey won’t be easy, but the destination is worth it. As we transition to a low-carbon economy, renewable hydrogen will play a vital role—not as a silver bullet, but as a powerful tool in our clean energy arsenal.

Frequently Asked Questions

What is renewable hydrogen?

Renewable hydrogen, also known as green hydrogen, is hydrogen gas produced by splitting water using electricity from renewable sources like wind, solar, or hydropower. Unlike gray hydrogen made from natural gas, it emits no carbon dioxide during production.

How is renewable hydrogen different from other types of hydrogen?

Renewable hydrogen is produced using clean energy and water, making it carbon-free. In contrast, gray hydrogen comes from fossil fuels and releases CO₂, while blue hydrogen captures some emissions but still relies on natural gas.

What are the main uses of renewable hydrogen?

Renewable hydrogen is used in heavy industry (like steel and chemicals), transportation (trucks, ships, trains), and energy storage. It can also replace fossil fuels in power generation and industrial heating.

Is renewable hydrogen safe?

Yes, hydrogen is safe when handled properly. It’s lighter than air and disperses quickly if leaked. Strict safety standards and proper infrastructure design minimize risks in storage and transport.

Can renewable hydrogen help fight climate change?

Absolutely. By replacing fossil fuels in hard-to-decarbonize sectors, renewable hydrogen can significantly reduce greenhouse gas emissions and support global climate goals like net-zero by 2050.

When will renewable hydrogen be widely available?

Renewable hydrogen is already being used in pilot projects and early commercial applications. Widespread adoption depends on lowering costs, building infrastructure, and scaling up renewable energy—progress is expected over the next 10–15 years.