Green hydrogen is emerging as a game-changer in the clean energy transition, offering a zero-emission fuel source powered entirely by renewable electricity. As technology advances and costs fall, green hydrogen is poised to revolutionize sectors from transportation to heavy industry, paving the way for a truly sustainable energy future.

Key Takeaways

- Green hydrogen is produced using renewable energy to split water into hydrogen and oxygen, emitting no carbon. This makes it a clean alternative to fossil fuel-based hydrogen.

- Electrolysis technology is rapidly improving, with PEM and alkaline systems leading the charge. Innovations are boosting efficiency and reducing costs.

- Scaling up renewable energy is critical to making green hydrogen economically viable. Solar and wind power are the primary drivers of production.

- Heavy industries like steel, cement, and chemicals are prime candidates for green hydrogen adoption. These sectors struggle to decarbonize using electricity alone.

- Government policies and international partnerships are accelerating investment and infrastructure development. Subsidies, tax credits, and green hydrogen hubs are gaining momentum.

- Challenges remain in storage, transportation, and cost competitiveness. But breakthroughs in materials science and logistics are steadily overcoming these hurdles.

- The future of green hydrogen depends on collaboration across sectors, innovation, and long-term policy support. With the right foundation, it can become a cornerstone of global decarbonization.

📑 Table of Contents

- Introduction: A Clean Fuel for a Cleaner Future

- What Is Green Hydrogen and How Is It Made?

- The Role of Renewable Energy in Green Hydrogen Production

- Technological Innovations Driving the Future

- Applications and Industries Leading the Adoption

- Challenges and Barriers to Widespread Adoption

- The Global Outlook and Future Trends

- Conclusion: Powering Tomorrow with Green Hydrogen

Introduction: A Clean Fuel for a Cleaner Future

Imagine a world where the fuel that powers our factories, trucks, and ships leaves no carbon footprint behind. No smog, no greenhouse gases, just clean energy driving progress. That world is no longer a distant dream—it’s being built right now, and green hydrogen is at the heart of it.

Hydrogen has long been hailed as a potential clean energy carrier. But not all hydrogen is created equal. Most hydrogen today is produced from natural gas in a process that releases significant amounts of carbon dioxide—this is known as “grey hydrogen.” There’s also “blue hydrogen,” which captures some of those emissions, but it still relies on fossil fuels. Green hydrogen, on the other hand, is different. It’s made by using renewable electricity—like wind or solar—to split water molecules into hydrogen and oxygen through a process called electrolysis. The result? A fuel that’s not only clean but also sustainable.

As the world races to meet climate goals and reduce dependence on fossil fuels, green hydrogen is stepping into the spotlight. It’s not just a niche solution for a few industries—it’s becoming a key player in the global energy transition. From powering long-haul trucks to helping steelmakers go carbon-neutral, green hydrogen is proving its versatility. And with technology advancing and costs dropping, the future of green hydrogen production looks brighter than ever.

What Is Green Hydrogen and How Is It Made?

Visual guide about The Future of Green Hydrogen Production

Image source: windfarmmanagement.skf.com

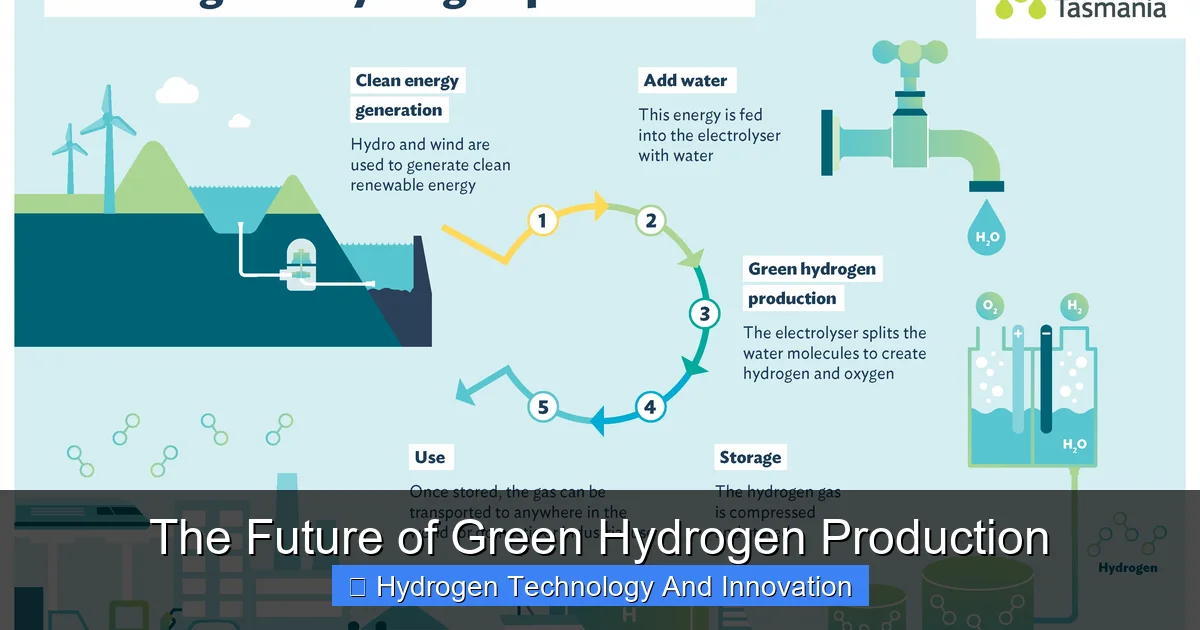

At its core, green hydrogen is hydrogen produced using renewable energy sources. The magic happens through electrolysis—a process that uses electricity to split water (H₂O) into its two components: hydrogen (H₂) and oxygen (O₂). When that electricity comes from wind, solar, or hydropower, the entire process emits zero carbon, making it truly green.

The Electrolysis Process Explained

Electrolysis might sound like something out of a science lab, but it’s actually a well-understood technology that’s been around for over a century. Here’s how it works: you take water and pass an electric current through it using two electrodes—an anode and a cathode—immersed in an electrolyte. At the cathode, hydrogen gas bubbles up. At the anode, oxygen is released. The only byproducts? Pure hydrogen and oxygen. No smoke, no fumes, no carbon.

There are three main types of electrolyzers used today:

- Alkaline Electrolyzers: These are the most mature and widely used. They use a liquid alkaline solution (like potassium hydroxide) as the electrolyte. They’re reliable and cost-effective but less flexible in responding to variable renewable energy inputs.

- Proton Exchange Membrane (PEM) Electrolyzers: These use a solid polymer membrane and can ramp up and down quickly, making them ideal for pairing with intermittent sources like solar and wind. They’re more expensive but offer higher efficiency and compactness.

- Solid Oxide Electrolyzers (SOEC): These operate at high temperatures and are highly efficient, especially when paired with waste heat from industrial processes. They’re still in the early stages of commercialization but hold great promise.

Each technology has its strengths, and the choice depends on the application, location, and energy source.

Why Green Hydrogen Stands Out

What sets green hydrogen apart is its environmental footprint—or lack thereof. Unlike grey or blue hydrogen, which rely on fossil fuels, green hydrogen production emits no CO₂. This makes it a critical tool for decarbonizing sectors that are hard to electrify directly, such as aviation, shipping, and heavy industry.

For example, consider steel production. Traditionally, this industry uses coal in blast furnaces, releasing massive amounts of carbon. But companies like Sweden’s HYBRIT are now using green hydrogen to reduce iron ore directly, eliminating the need for coal and cutting emissions by up to 90%. That’s a game-changer.

The Role of Renewable Energy in Green Hydrogen Production

Green hydrogen is only as clean as the electricity used to produce it. That’s why renewable energy is the backbone of its future. Without abundant, affordable wind and solar power, green hydrogen can’t scale.

Solar and Wind: The Power Duo

Solar and wind energy are the most common sources for green hydrogen production. Their costs have plummeted over the past decade—solar photovoltaic (PV) costs have dropped by over 80% since 2010, and onshore wind by nearly 70%. This makes them not just environmentally friendly but also economically attractive.

In sunny regions like Australia, the Middle East, and parts of the U.S. Southwest, large-scale solar farms are being paired with electrolyzers to produce hydrogen. Australia’s Asian Renewable Energy Hub, for instance, aims to generate 26 gigawatts of wind and solar power to produce green hydrogen and ammonia for export. That’s enough to power millions of homes—or fuel thousands of ships and trucks.

Wind energy, especially offshore wind, is another major player. Countries like Germany and the UK are investing heavily in offshore wind farms that can power hydrogen production hubs near ports. These hubs can then supply hydrogen to ships, trucks, and nearby industries.

Hydropower and Geothermal: Reliable Alternatives

While solar and wind dominate, other renewables also play a role. Hydropower provides consistent, baseload electricity, making it ideal for steady hydrogen production. Norway, for example, uses its abundant hydropower to produce green hydrogen for domestic use and export.

Geothermal energy, though less widespread, offers another stable source. In Iceland, geothermal plants are exploring hydrogen production to diversify their energy exports. The key is matching the energy source to the local geography and demand.

Overcoming Intermittency Challenges

One challenge with solar and wind is their variability—the sun doesn’t always shine, and the wind doesn’t always blow. This can disrupt hydrogen production. But solutions are emerging.

Energy storage systems, like batteries, can store excess renewable energy for use during low-generation periods. Alternatively, hybrid systems that combine multiple renewables can smooth out supply. For example, a solar-wind hybrid plant can generate power more consistently than either source alone.

Smart grid technology also helps. By forecasting weather patterns and adjusting electrolyzer operations in real time, producers can maximize efficiency and minimize waste.

Technological Innovations Driving the Future

The future of green hydrogen isn’t just about scaling up existing technology—it’s about innovating to make production faster, cheaper, and more efficient.

Next-Generation Electrolyzers

Researchers and companies are pushing the boundaries of electrolyzer design. One exciting development is the use of advanced catalysts. Traditional electrolyzers use expensive materials like platinum and iridium. New catalysts made from abundant, low-cost materials—such as nickel, iron, or cobalt—are being tested to reduce costs without sacrificing performance.

Another breakthrough is in membrane technology. PEM electrolyzers are getting thinner, more durable, and more conductive, allowing for higher current densities and faster hydrogen output. Some prototypes now achieve efficiencies above 80%, meaning more hydrogen per unit of electricity.

Modular and Scalable Systems

Modularity is key to scaling green hydrogen. Instead of building massive, centralized plants, companies are developing modular electrolyzer units that can be deployed quickly and scaled as needed. These “hydrogen hubs” can be installed near renewable energy sources or industrial sites, reducing transmission losses and infrastructure costs.

For example, Plug Power in the U.S. offers plug-and-play hydrogen production systems that can be set up in weeks. These systems are being used in warehouses, data centers, and even forklift fleets, proving that green hydrogen isn’t just for heavy industry.

Integration with AI and Automation

Artificial intelligence is playing a growing role in optimizing green hydrogen production. AI algorithms can predict energy demand, adjust electrolyzer output, and detect maintenance needs before failures occur. This not only improves efficiency but also reduces downtime and operational costs.

Automation is also streamlining operations. Remote monitoring systems allow operators to manage multiple hydrogen plants from a central location, making large-scale deployment more feasible.

Applications and Industries Leading the Adoption

Green hydrogen isn’t just a lab experiment—it’s already being used in real-world applications across multiple sectors.

Heavy Industry: Steel, Cement, and Chemicals

Industries that require high heat or chemical reactions are prime candidates for green hydrogen. Steelmaking, as mentioned, is a major focus. In addition to HYBRIT, companies like ArcelorMittal and Thyssenkrupp are piloting hydrogen-based direct reduced iron (DRI) processes.

Cement production, another carbon-intensive industry, is also exploring hydrogen. While most cement emissions come from chemical reactions (not fuel), hydrogen can replace fossil fuels in kilns, reducing overall emissions.

The chemical industry uses hydrogen as a feedstock for producing ammonia, methanol, and other compounds. Traditionally, this hydrogen comes from natural gas. Switching to green hydrogen can drastically cut the carbon footprint of these products.

Transportation: Trucks, Ships, and Planes

Transportation is a major source of emissions, and while electric vehicles (EVs) are growing, they’re not ideal for all uses. Long-haul trucks, ships, and airplanes need high-energy-density fuels that can be stored and transported easily—enter hydrogen.

Hydrogen fuel cell trucks are already on the road. Companies like Nikola and Toyota are developing hydrogen-powered semis that can travel over 500 miles on a single fill. These trucks refuel in minutes, unlike battery EVs that require hours of charging.

In shipping, green hydrogen is being converted into ammonia or liquid organic hydrogen carriers (LOHCs) for easier transport. The International Maritime Organization (IMO) has set targets to cut shipping emissions by 50% by 2050, and green hydrogen is a key part of that strategy.

Aviation is also exploring hydrogen. Airbus has announced plans to develop hydrogen-powered aircraft by 2035, with prototypes already in testing. While challenges remain—especially around storage and airport infrastructure—the potential is enormous.

Energy Storage and Grid Balancing

Green hydrogen can also serve as a form of long-term energy storage. Excess renewable energy can be used to produce hydrogen, which is then stored and converted back to electricity when needed using fuel cells. This helps balance the grid and ensures a stable power supply even when the sun isn’t shining or the wind isn’t blowing.

Countries like Germany and Japan are investing in hydrogen-based grid stabilization projects. In Australia, the proposed Hydrogen Energy Supply Chain (HESC) project aims to export green hydrogen to Japan for use in power generation.

Challenges and Barriers to Widespread Adoption

Despite its promise, green hydrogen faces several hurdles that must be overcome for it to reach its full potential.

High Production Costs

Currently, green hydrogen is more expensive than grey or blue hydrogen. The main cost drivers are electricity and electrolyzers. While renewable energy prices are falling, electrolyzers still account for a significant portion of the total cost.

However, costs are expected to drop as production scales up. The International Renewable Energy Agency (IRENA) estimates that green hydrogen could become cost-competitive with grey hydrogen by 2030 in many regions, especially where renewable energy is cheap.

Storage and Transportation

Hydrogen is a tricky molecule to handle. It’s the lightest element, highly flammable, and tends to leak through materials. Storing it requires high pressure (for gas) or very low temperatures (for liquid), both of which are energy-intensive.

Transporting hydrogen over long distances is also challenging. Pipelines can be used, but they require special materials to prevent embrittlement. Alternatively, hydrogen can be converted into ammonia or other carriers for easier transport, but this adds complexity and cost.

Infrastructure Gaps

There’s a lack of infrastructure for hydrogen production, distribution, and refueling. Unlike gasoline or electricity, hydrogen refueling stations are rare, and hydrogen pipelines are limited. Building this infrastructure requires significant investment and coordination.

However, governments and private companies are stepping up. The European Union’s Hydrogen Strategy aims to install 40 GW of electrolyzers by 2030. The U.S. has launched the Regional Clean Hydrogen Hubs program, funding seven major projects across the country.

Policy and Regulatory Support

Clear, consistent policies are essential to drive investment. Subsidies, tax credits, and carbon pricing can level the economic playing field. The U.S. Inflation Reduction Act, for example, offers a production tax credit of up to $3 per kilogram of green hydrogen, making it much more competitive.

International cooperation is also key. Countries are forming alliances like the Green Hydrogen Catapult to accelerate deployment and share best practices.

The Global Outlook and Future Trends

The future of green hydrogen is bright, with momentum building worldwide.

Regional Leaders and Emerging Markets

Europe is leading the charge, with ambitious targets and strong policy support. Germany, France, and the Netherlands are investing billions in hydrogen infrastructure. The EU’s REPowerEU plan aims to produce 10 million tons of domestic green hydrogen by 2030.

Australia and the Middle East are positioning themselves as global exporters, leveraging their abundant solar and wind resources. Chile, with its vast deserts and strong winds, is also emerging as a green hydrogen hub.

In Asia, Japan and South Korea are investing heavily in hydrogen for transportation and industry. China, while still reliant on coal-based hydrogen, is rapidly expanding its renewable capacity and could become a major player in green hydrogen.

Projected Growth and Investment

According to BloombergNEF, global green hydrogen production could reach 30 million tons per year by 2030, up from less than 1 million today. Investment is surging, with over $300 billion committed to hydrogen projects worldwide.

As technology improves and economies of scale kick in, costs are expected to fall dramatically. Electrolyzer prices could drop by 70% by 2030, and green hydrogen could cost as little as $1–$2 per kilogram in optimal locations—making it competitive with fossil fuels.

The Path to a Hydrogen Economy

The ultimate vision is a “hydrogen economy,” where hydrogen is used widely across energy, industry, and transport. While this may take decades, the foundation is being laid today.

Success will depend on continued innovation, supportive policies, and global collaboration. But if the momentum continues, green hydrogen could become one of the most important clean energy solutions of the 21st century.

Conclusion: Powering Tomorrow with Green Hydrogen

Green hydrogen is more than just a buzzword—it’s a transformative technology with the power to reshape our energy landscape. By harnessing renewable electricity to produce a clean, versatile fuel, we can decarbonize industries that were once thought impossible to clean up.

From steel mills to shipping lanes, from remote villages to bustling cities, green hydrogen is opening new doors to a sustainable future. Yes, challenges remain—costs, infrastructure, and logistics—but every day, innovators, policymakers, and businesses are finding solutions.

The future of green hydrogen production isn’t just about technology. It’s about vision, collaboration, and the shared goal of leaving a healthier planet for future generations. As we continue to invest in this clean energy frontier, one thing is clear: green hydrogen isn’t just the future—it’s already here.

Frequently Asked Questions

What makes green hydrogen different from other types of hydrogen?

Green hydrogen is produced using renewable energy to split water into hydrogen and oxygen, emitting no carbon dioxide. In contrast, grey hydrogen is made from natural gas and releases CO₂, while blue hydrogen captures some emissions but still relies on fossil fuels.

How efficient is green hydrogen production?

Current electrolyzers achieve efficiencies of 60–80%, depending on the technology. PEM and solid oxide electrolyzers are among the most efficient, especially when paired with renewable energy sources and optimized operating conditions.

Can green hydrogen be used in existing vehicles?

Hydrogen fuel cell vehicles require specialized infrastructure and vehicles designed for hydrogen. While you can’t use green hydrogen in a standard gasoline car, fuel cell electric vehicles (FCEVs) like the Toyota Mirai are already on the market and compatible with green hydrogen.

Is green hydrogen safe to store and transport?

Hydrogen is flammable and requires careful handling, but with proper safety measures—such as high-strength tanks, leak detection systems, and ventilation—it can be stored and transported safely. Industry standards and regulations are continually improving to ensure safety.

How much does green hydrogen cost compared to fossil fuels?

Currently, green hydrogen costs $3–$8 per kilogram, making it more expensive than grey hydrogen. However, as renewable energy and electrolyzer costs fall, it’s expected to reach $1–$2 per kilogram by 2030, becoming competitive with fossil fuels in many applications.

What role do governments play in green hydrogen development?

Governments are critical in driving green hydrogen through policies, subsidies, and infrastructure investment. Programs like the U.S. Hydrogen Hubs, the EU Hydrogen Strategy, and international partnerships are accelerating research, deployment, and market creation.