Renewable energy is transforming hydrogen fuel production by enabling clean, sustainable methods like electrolysis powered by solar, wind, and hydropower. This shift reduces carbon emissions and supports global decarbonization goals, making green hydrogen a cornerstone of the clean energy transition.

Key Takeaways

- Renewable energy enables green hydrogen production: Solar, wind, and hydropower can power electrolysis to split water into hydrogen and oxygen without emitting greenhouse gases.

- Green hydrogen reduces carbon footprints: Unlike gray or blue hydrogen, green hydrogen produced with renewables has near-zero lifecycle emissions.

- Electrolysis is the key technology: Proton exchange membrane (PEM) and alkaline electrolyzers are becoming more efficient and cost-effective with renewable integration.

- Energy storage and grid stability benefit: Excess renewable energy can be stored as hydrogen, helping balance supply and demand on the grid.

- Government policies and investments are accelerating adoption: Countries like Germany, Japan, and Australia are leading in green hydrogen initiatives and funding.

- Industrial and transportation sectors are key markets: Green hydrogen can decarbonize hard-to-abate industries like steel, chemicals, and heavy transport.

- Challenges remain in cost and infrastructure: Scaling up requires lower electrolyzer costs, better storage solutions, and expanded distribution networks.

📑 Table of Contents

- Introduction: The Hydrogen Revolution Powered by Renewables

- How Renewable Energy Powers Hydrogen Production

- Environmental Benefits of Green Hydrogen

- Economic and Technological Advancements

- Applications and Market Opportunities

- Challenges and the Path Forward

- Conclusion: A Clean Energy Future Powered by Renewables and Hydrogen

Introduction: The Hydrogen Revolution Powered by Renewables

Imagine a world where the fuel that powers our cars, heats our homes, and runs our factories produces no harmful emissions. That world is no longer a distant dream—it’s being built today, and renewable energy is at the heart of it. Hydrogen, the most abundant element in the universe, is emerging as a clean energy carrier with the potential to revolutionize how we store and use energy. But not all hydrogen is created equal. The color-coded system—gray, blue, and green—tells a story of environmental impact, and only one color truly delivers on the promise of sustainability: green hydrogen.

Green hydrogen is produced using renewable energy sources like solar, wind, and hydropower to power a process called electrolysis. This method splits water (H₂O) into hydrogen and oxygen, with no carbon dioxide released in the process. Unlike gray hydrogen, which relies on natural gas and emits significant CO₂, or blue hydrogen, which captures some emissions but still depends on fossil fuels, green hydrogen offers a truly clean alternative. As the world races to meet climate goals and reduce reliance on fossil fuels, renewable-powered hydrogen production is stepping into the spotlight as a game-changer.

How Renewable Energy Powers Hydrogen Production

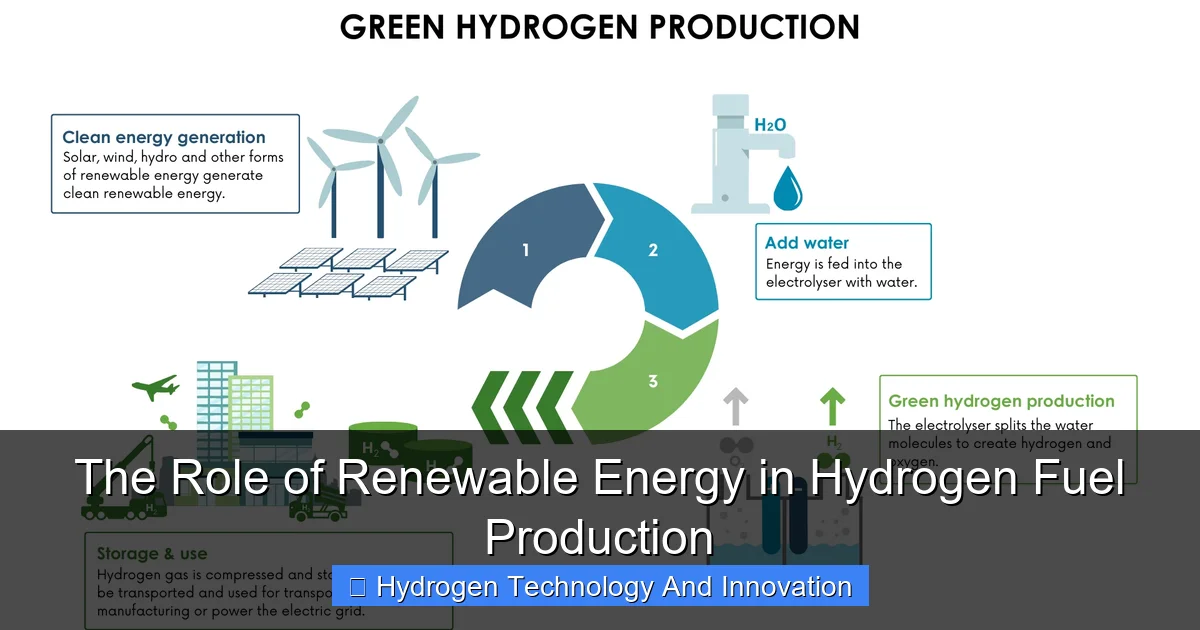

Visual guide about The Role of Renewable Energy in Hydrogen Fuel Production

Image source: dep.nj.gov

At the core of green hydrogen production is electrolysis—a clean, electrochemical process that uses electricity to break water molecules into hydrogen and oxygen. When that electricity comes from renewable sources, the entire production cycle becomes emissions-free. This synergy between renewables and hydrogen is not just environmentally beneficial; it’s also increasingly economically viable.

The Electrolysis Process Explained

Electrolysis works by passing an electric current through water in a device called an electrolyzer. The water molecules split into hydrogen gas (H₂) at the cathode and oxygen gas (O₂) at the anode. The hydrogen is then collected, purified, and stored for later use. The key to making this process green is ensuring the electricity driving it comes from renewable sources like solar panels, wind turbines, or hydroelectric dams.

There are several types of electrolyzers, but the most common for renewable integration are alkaline and proton exchange membrane (PEM) systems. Alkaline electrolyzers are mature and cost-effective, ideal for large-scale operations. PEM electrolyzers, while more expensive, offer faster response times and better compatibility with variable renewable inputs—making them perfect for solar and wind farms that don’t generate power 24/7.

Matching Renewables to Hydrogen Production

One of the biggest advantages of using renewable energy for hydrogen production is flexibility. Solar and wind power are intermittent—they generate electricity only when the sun shines or the wind blows. But instead of letting that excess energy go to waste, it can be used to produce hydrogen during peak generation times. This turns a challenge into an opportunity.

For example, a solar farm in sunny Australia might generate more electricity than the grid can absorb during midday. Instead of curtailment (wasting the energy), that power can be diverted to an electrolyzer to produce hydrogen. The hydrogen can then be stored and used later—when the sun sets, during cloudy days, or even shipped to other regions. This not only maximizes the value of renewable energy but also provides a reliable energy storage solution.

Real-World Examples of Renewable-Powered Hydrogen

Several projects around the world are already proving the viability of this model. In Germany, the HySupply project combines wind energy with PEM electrolysis to produce green hydrogen for industrial use. Similarly, in Chile’s Atacama Desert, the HIF (Highly Innovative Fuels) project uses solar power to produce green hydrogen and e-fuels for export.

Australia is another leader, with the Asian Renewable Energy Hub planning to use 14 gigawatts of wind and solar to produce green hydrogen and ammonia for domestic use and international markets. These projects demonstrate that renewable-powered hydrogen production is not just theoretical—it’s happening now, at scale.

Environmental Benefits of Green Hydrogen

The environmental case for green hydrogen is compelling. As nations strive to meet net-zero emissions targets, decarbonizing sectors that are hard to electrify—like heavy industry and long-haul transport—is a major challenge. Green hydrogen offers a solution.

Zero Carbon Emissions at the Point of Production

Unlike fossil fuel-based hydrogen production, which emits up to 10 kilograms of CO₂ for every kilogram of hydrogen, green hydrogen production emits virtually no greenhouse gases. When powered by renewables, the only byproducts are hydrogen and oxygen—both clean and non-toxic. This makes green hydrogen a critical tool in reducing the carbon footprint of energy-intensive industries.

Lifecycle Emissions: A Full Picture

It’s important to consider the entire lifecycle of hydrogen production, not just the electrolysis step. This includes the manufacturing of electrolyzers, the construction of renewable energy infrastructure, and the transportation of hydrogen. Studies show that even when accounting for these factors, green hydrogen still has a significantly lower carbon footprint than gray or blue hydrogen.

For instance, a 2022 report by the International Energy Agency (IEA) found that green hydrogen produced with wind power has lifecycle emissions of less than 1 kg CO₂ per kg of hydrogen—compared to over 10 kg for gray hydrogen. This dramatic difference underscores the importance of using renewable energy in the production process.

Supporting Biodiversity and Reducing Pollution

Beyond carbon emissions, green hydrogen production also reduces other forms of environmental harm. Fossil fuel extraction and refining contribute to air and water pollution, habitat destruction, and health risks for nearby communities. By shifting to renewable-powered hydrogen, we can reduce reliance on these harmful practices and protect ecosystems.

Moreover, green hydrogen can replace fossil fuels in applications like ammonia production (used in fertilizers) and methanol synthesis, further cutting industrial pollution. As renewable energy infrastructure expands, the environmental benefits will only grow.

Economic and Technological Advancements

The economics of green hydrogen are improving rapidly, thanks to falling renewable energy costs and advances in electrolyzer technology. What was once considered too expensive is now becoming competitive—especially in regions with abundant solar or wind resources.

Falling Costs of Renewable Energy

The cost of solar and wind power has dropped dramatically over the past decade. According to the International Renewable Energy Agency (IRENA), the global weighted average cost of electricity from solar photovoltaics fell by 89% between 2010 and 2022. Wind power saw similar declines. This makes renewable energy one of the cheapest sources of electricity in many parts of the world.

Since electricity is the main input cost in green hydrogen production, these price drops directly reduce the cost of hydrogen. In sunny regions like the Middle East or Australia, green hydrogen is already approaching cost parity with gray hydrogen—especially when carbon pricing is factored in.

Improving Electrolyzer Efficiency and Durability

Electrolyzer technology is also advancing. Modern PEM and alkaline electrolyzers are becoming more efficient, durable, and scalable. New materials and manufacturing techniques are reducing costs and increasing lifespan. For example, researchers are developing electrolyzers that can operate at higher temperatures and pressures, improving efficiency and reducing energy losses.

Startups and major industrial players alike are investing in next-generation systems. Companies like ITM Power, Nel Hydrogen, and Siemens Energy are scaling up production and driving innovation. As manufacturing scales, economies of scale will further reduce costs.

Government Support and Investment

Governments around the world are recognizing the strategic importance of green hydrogen and are stepping in with funding and policy support. The European Union’s Hydrogen Strategy aims to install 40 gigawatts of electrolyzers by 2030. The U.S. Inflation Reduction Act includes tax credits of up to $3 per kilogram for clean hydrogen production, making green hydrogen highly competitive.

Japan and South Korea have launched national hydrogen strategies, while Australia and Canada are positioning themselves as green hydrogen exporters. These investments are accelerating deployment and helping to build the supply chains needed for a hydrogen economy.

Applications and Market Opportunities

Green hydrogen isn’t just for power generation—it has a wide range of applications across industries. Its versatility makes it a valuable tool for decarbonization.

Industrial Use: Decarbonizing Heavy Industry

Industries like steel, cement, and chemicals are among the hardest to decarbonize because they require high-temperature heat and chemical processes that are difficult to electrify. Green hydrogen can replace coal and natural gas in these applications.

For example, in steelmaking, hydrogen can be used in direct reduced iron (DRI) processes, eliminating the need for coal-based blast furnaces. Swedish company HYBRIT has already demonstrated a pilot plant that produces fossil-free steel using green hydrogen. Similar innovations are underway in the chemical sector, where hydrogen is a key feedstock for producing ammonia and methanol.

Transportation: Fuel for the Future

Green hydrogen can power fuel cell electric vehicles (FCEVs), offering long range and fast refueling—advantages over battery electric vehicles for heavy-duty transport. Trucks, buses, ships, and even airplanes are exploring hydrogen as a clean fuel.

In Germany, hydrogen-powered trains are already in service on non-electrified rail lines. In Japan, hydrogen refueling stations support a growing fleet of FCEVs. While battery electric vehicles dominate passenger cars, hydrogen is gaining traction in sectors where weight and range are critical.

Energy Storage and Grid Balancing

One of the most promising roles for green hydrogen is long-duration energy storage. Unlike batteries, which are best for short-term storage, hydrogen can be stored for weeks or months. This makes it ideal for balancing seasonal variations in renewable energy supply.

For example, excess solar energy generated in summer can be converted to hydrogen and stored underground in salt caverns or depleted gas fields. When winter demand peaks and solar output drops, the hydrogen can be converted back to electricity using fuel cells or gas turbines.

This capability is especially valuable in regions with high renewable penetration, where grid stability becomes a challenge. Green hydrogen acts as a buffer, ensuring a reliable energy supply even when the sun isn’t shining or the wind isn’t blowing.

Challenges and the Path Forward

Despite its promise, green hydrogen faces several challenges that must be addressed to achieve widespread adoption.

High Production and Infrastructure Costs

While costs are falling, green hydrogen is still more expensive than fossil-based alternatives in many markets. Electrolyzers, storage tanks, and transportation infrastructure require significant upfront investment. Building a hydrogen economy will need coordinated efforts across governments, industries, and investors.

Storage and Transportation Challenges

Hydrogen is a lightweight, low-density gas, making it difficult and expensive to store and transport. It requires high-pressure tanks, cryogenic temperatures, or chemical carriers like ammonia. Developing safe, efficient, and cost-effective solutions is essential.

Pipelines can be used for transport, but most existing gas pipelines aren’t suitable for pure hydrogen without modifications. New infrastructure will be needed, especially for cross-border trade.

Scaling Up Renewable Capacity

Producing large quantities of green hydrogen requires massive amounts of renewable energy. Scaling up solar and wind farms to meet this demand will require land, permitting, and grid upgrades. In some regions, land use conflicts or regulatory hurdles could slow progress.

The Need for Standards and Certification

To ensure credibility, green hydrogen must be certified as truly low-carbon. Standards for measuring and verifying emissions across the supply chain are still evolving. International cooperation will be key to establishing consistent criteria and avoiding greenwashing.

Conclusion: A Clean Energy Future Powered by Renewables and Hydrogen

The role of renewable energy in hydrogen fuel production is not just important—it’s essential. Green hydrogen, powered by solar, wind, and hydropower, offers a clean, scalable solution to some of the world’s most pressing energy and climate challenges. From decarbonizing heavy industry to enabling long-term energy storage, its potential is vast.

While challenges remain, the momentum is undeniable. Falling costs, technological advances, and strong policy support are driving rapid growth. As renewable energy capacity expands and electrolyzer technology improves, green hydrogen will become increasingly competitive and accessible.

The transition to a hydrogen economy won’t happen overnight, but every solar panel installed, every wind turbine erected, and every electrolyzer deployed brings us closer. By harnessing the power of renewables to produce clean hydrogen, we’re not just changing how we make fuel—we’re building a more sustainable, resilient, and equitable energy future for all.

Frequently Asked Questions

What is green hydrogen and how is it different from other types of hydrogen?

Green hydrogen is produced by using renewable energy to power electrolysis, splitting water into hydrogen and oxygen with no carbon emissions. Unlike gray hydrogen (made from natural gas) or blue hydrogen (which captures some emissions), green hydrogen is truly clean and sustainable.

Can renewable energy really power large-scale hydrogen production?

Yes. Solar and wind farms can generate excess electricity during peak times, which can be used to produce hydrogen via electrolysis. This not only maximizes renewable energy use but also provides a way to store and transport clean energy.

Is green hydrogen cost-competitive with fossil fuels?

In regions with abundant renewable resources, green hydrogen is becoming increasingly cost-competitive, especially with government incentives and falling technology costs. While still more expensive than gray hydrogen in some areas, the gap is narrowing rapidly.

What industries can benefit most from green hydrogen?

Heavy industries like steel, chemicals, and cement, as well as transportation sectors such as shipping, aviation, and heavy-duty trucking, can significantly reduce emissions by switching to green hydrogen.

How is green hydrogen stored and transported?

Green hydrogen can be stored in high-pressure tanks, as a liquid at very low temperatures, or converted into carriers like ammonia. It can be transported via pipelines, trucks, or ships, though infrastructure development is still ongoing.

What role do governments play in advancing green hydrogen?

Governments support green hydrogen through funding, tax credits, research grants, and policy frameworks. Initiatives like the EU Hydrogen Strategy and the U.S. Inflation Reduction Act are accelerating investment and deployment worldwide.